Planetary gearbox sun gear gradient pitting corrosion time-varying meshing stiffness analysis method

A time-varying mesh stiffness, planetary gearbox technology, applied in the field of dynamic modeling and signal analysis, can solve problems such as increased impact, increased tooth surface erosion, difficult to distinguish, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

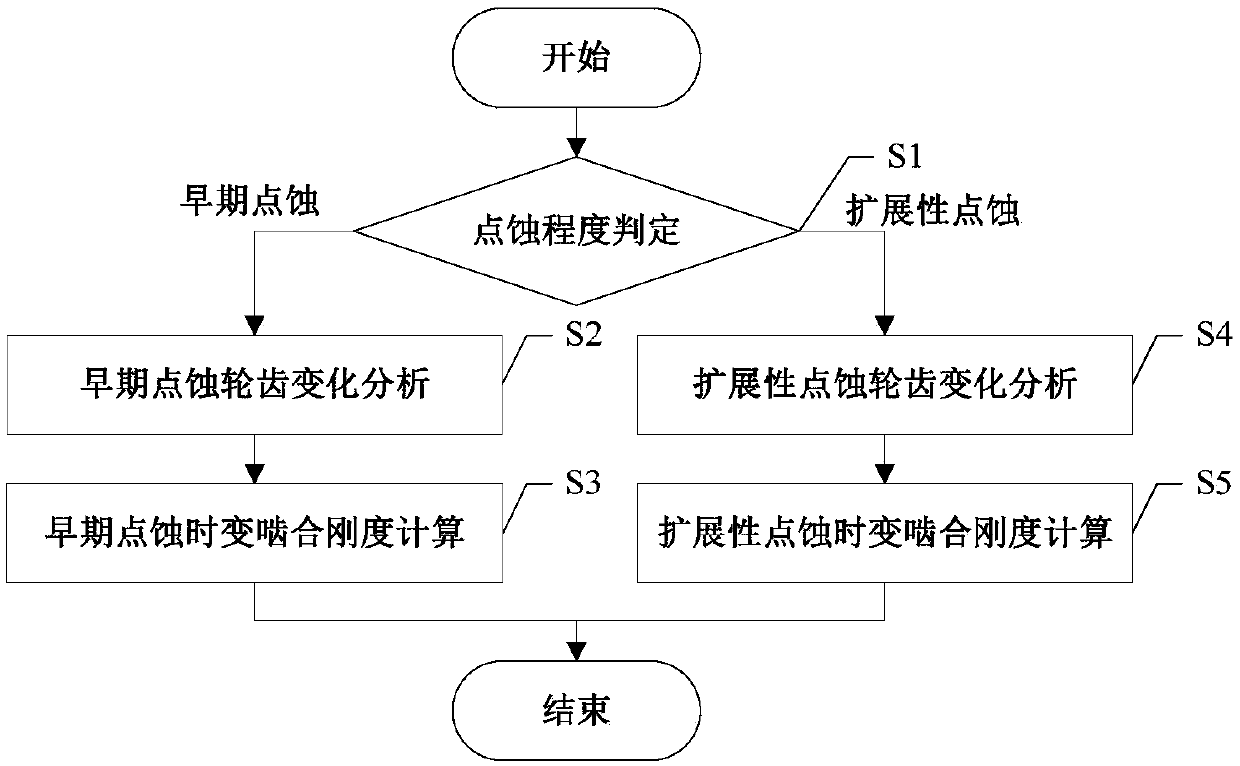

[0065] Such as figure 2 Shown is the scheme flow chart of the present invention, the technical scheme of the present invention is: planetary gear box sun gear gradual change pitting time-varying meshing stiffness analysis method, comprises the following steps:

[0066] S1. Judgment of pitting degree: According to the running time of the planetary gearbox, the tooth surface pitting is divided into two stages: early pitting and extended pitting.

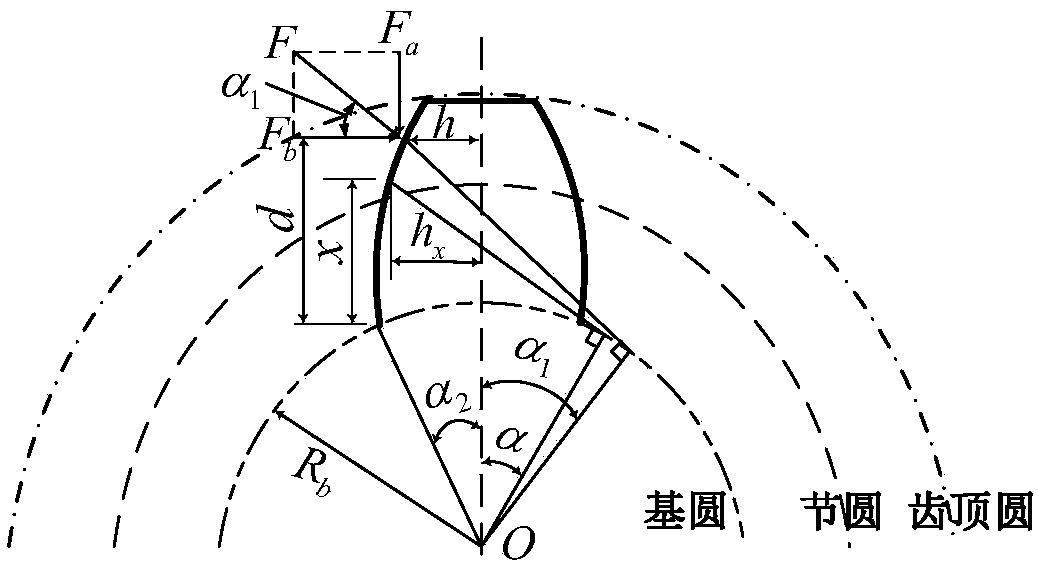

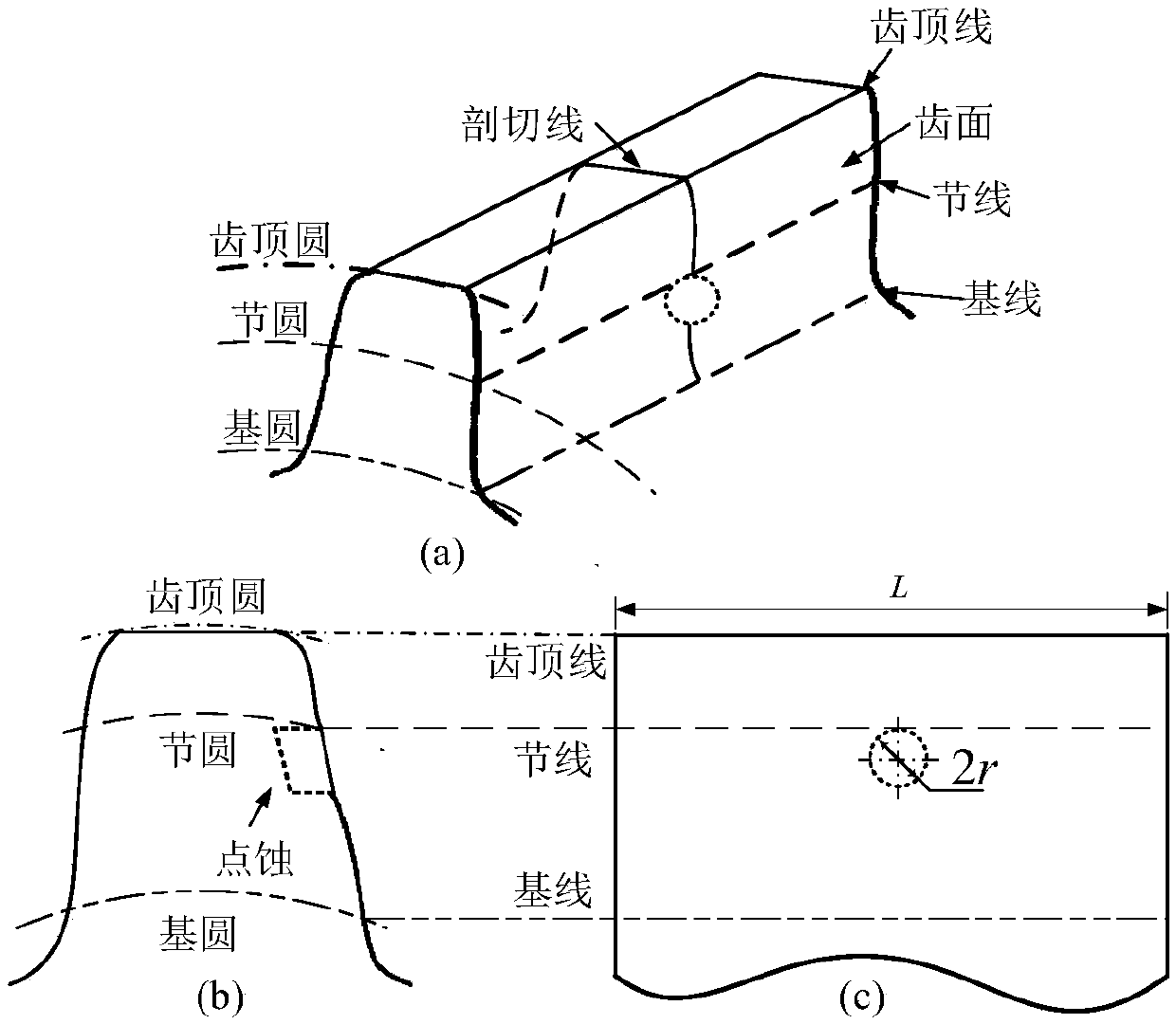

[0067] In the early stage of pitting, the pits or small fatigue pits on the tooth surface occur at the root of the tooth near the pitch line; when they continue to expand, the fatigue pits along the contact line increase and the number increases, and Interconnected to form denudation scars and change th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com