Automatic varnishing temperature control device and method

A temperature control device and automatic technology, which is applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problem of not being able to fully guarantee the consistency of insulating paint viscosity, failing to meet the painting process conditions, affecting the painting quality and Stability and other issues to achieve the effect of avoiding quality instability, reducing scrap rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

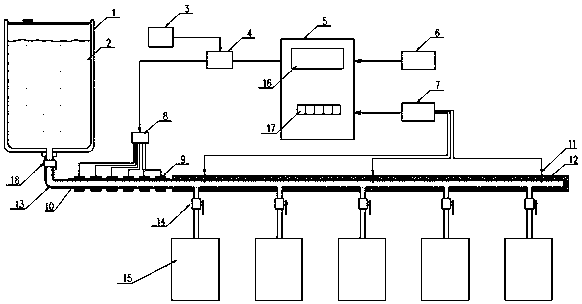

[0014] An automatic paint temperature control device, including a paint storage tank 1, a relay unit 4, a multi-channel temperature controller 5, a terminal box 8, a ceramic heating tile 9, a heat conduction layer 10, a temperature sensor 11, an insulation layer 12, and a main pipe 13. Branch pipeline valve 14, painting room 15 and main pipeline main valve 18, the paint storage tank 1 and the main pipeline 13 are connected to each other through the main pipeline main valve 18, and the main pipeline 13 and the painting room 15 pass through the branch pipeline valve 14 connected to each other, the insulation layer 12 is coated on the outside of the main pipeline 13, the heat conducting layer 10 is coated on the initial section of the main pipeline 13, the ceramic heating tile 9 is installed on the heat conducting layer 10, and the temperature senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com