UHV DC converter valve two-port circuit

An ultra-high voltage DC, two-port technology, applied in CAD circuit design, special data processing applications, design optimization/simulation, etc., can solve the inconvenience of transient voltage analysis between valve tower layers, low simulation efficiency, high time complexity and Space complexity and other issues, to achieve the effect of shortening extraction time and computational complexity, improving efficiency, and shortening modeling and simulation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

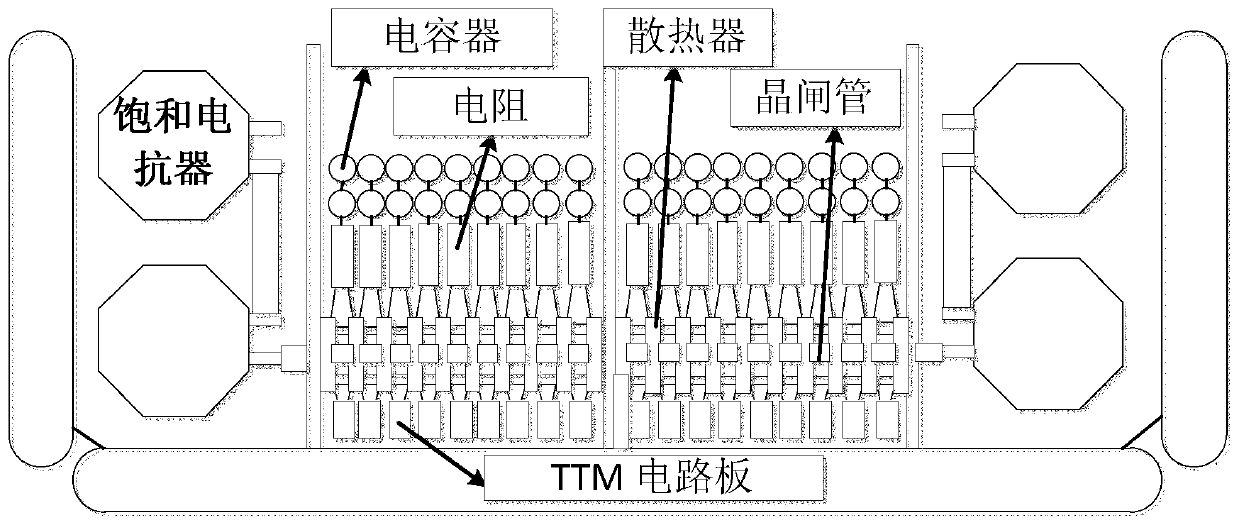

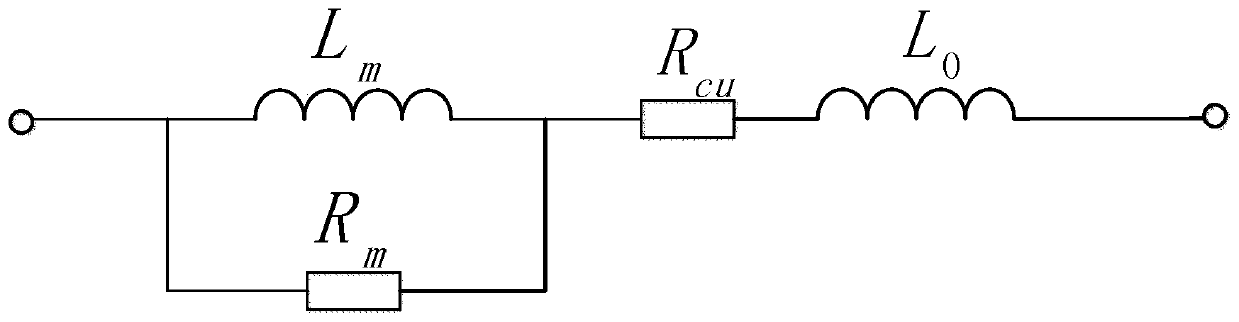

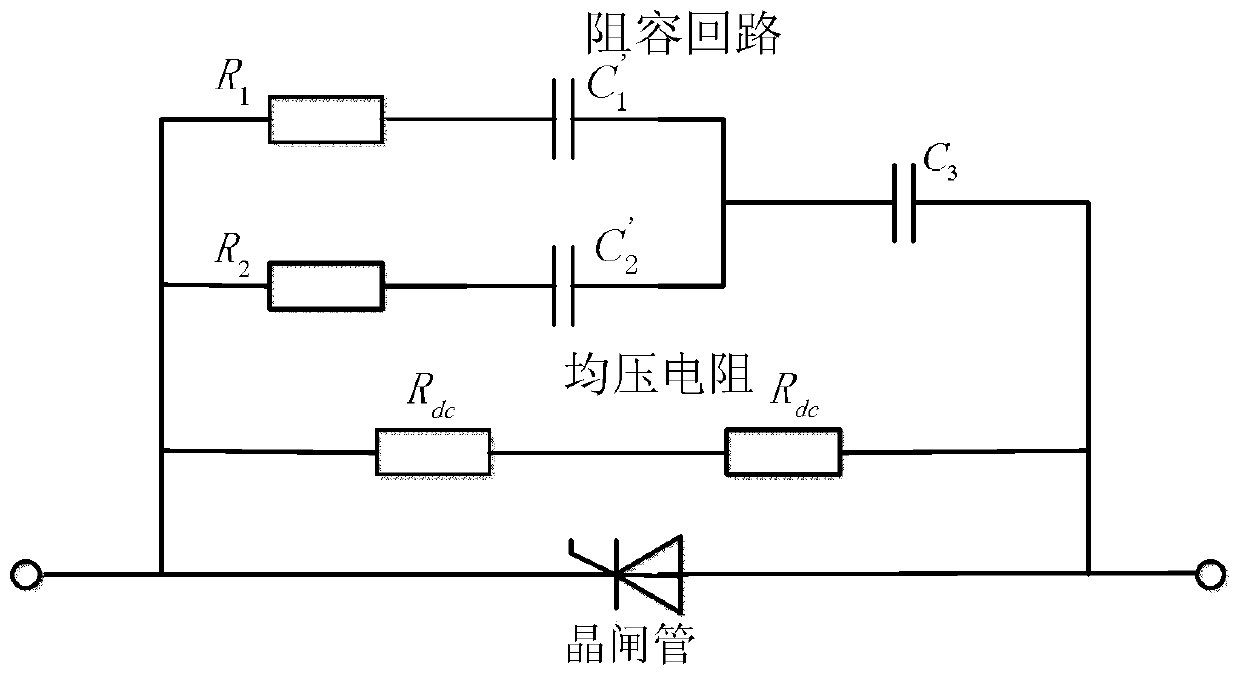

[0058] The present invention takes the ±1100kV UHV converter valve tower as an example, and establishes a two-port equivalent circuit model for it. The ±1100kV converter valve is a double valve with 7 layers in total, the top layer and the bottom layer are respectively a large pressure equalizing ring and a shielding cover. The valve structure of each layer of the middle 5 layers is composed of two converter valve modules placed side by side. The three-dimensional model structure of each valve module is as follows: figure 1 As shown, each valve module is composed of two valve assemblies, the valve assembly includes 2 saturable reactors and 9 thyristor stages, through the insulating structural support, thyristor press-fit structure, saturable reactor, damping resistance unit, damping Capacitor units, gate units, wires and water pipes are connected to each other. The saturable reactor is connected in series with the anode terminal of the thyristor element. attached figure 2 ...

Embodiment 2

[0061] The present invention takes the ±1100kV UHV converter valve tower as an example to extract the equivalent parasitic capacitance of the valve layer port. Figure 9 The three-dimensional model of the shielding cover of the valve tower is shown. The shielding cover of the ±1100kV converter valve adopts a split pressure equalization design. The short shield has two large grading rings symmetrically distributed on the top and two large shields symmetrically distributed on the bottom, connected by 6 oblique busbars and 5 horizontal busbars. Each conductor of the shield does not exist in isolation, but forms a potential relationship through potential clamping and connecting busbars. Specifically, each valve layer is composed of two valve modules, and a total of 4 shields are connected to the outside of each valve module, including 2 corner shields and 2 short shields. The two corner shields are respectively equal to the start potential of the first saturable reactor in the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com