Battery tab welding equipment and welding method

A technology for welding equipment and battery tabs, which is applied to welding equipment, non-electric welding equipment, battery pack components, etc. Improve welding accuracy and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

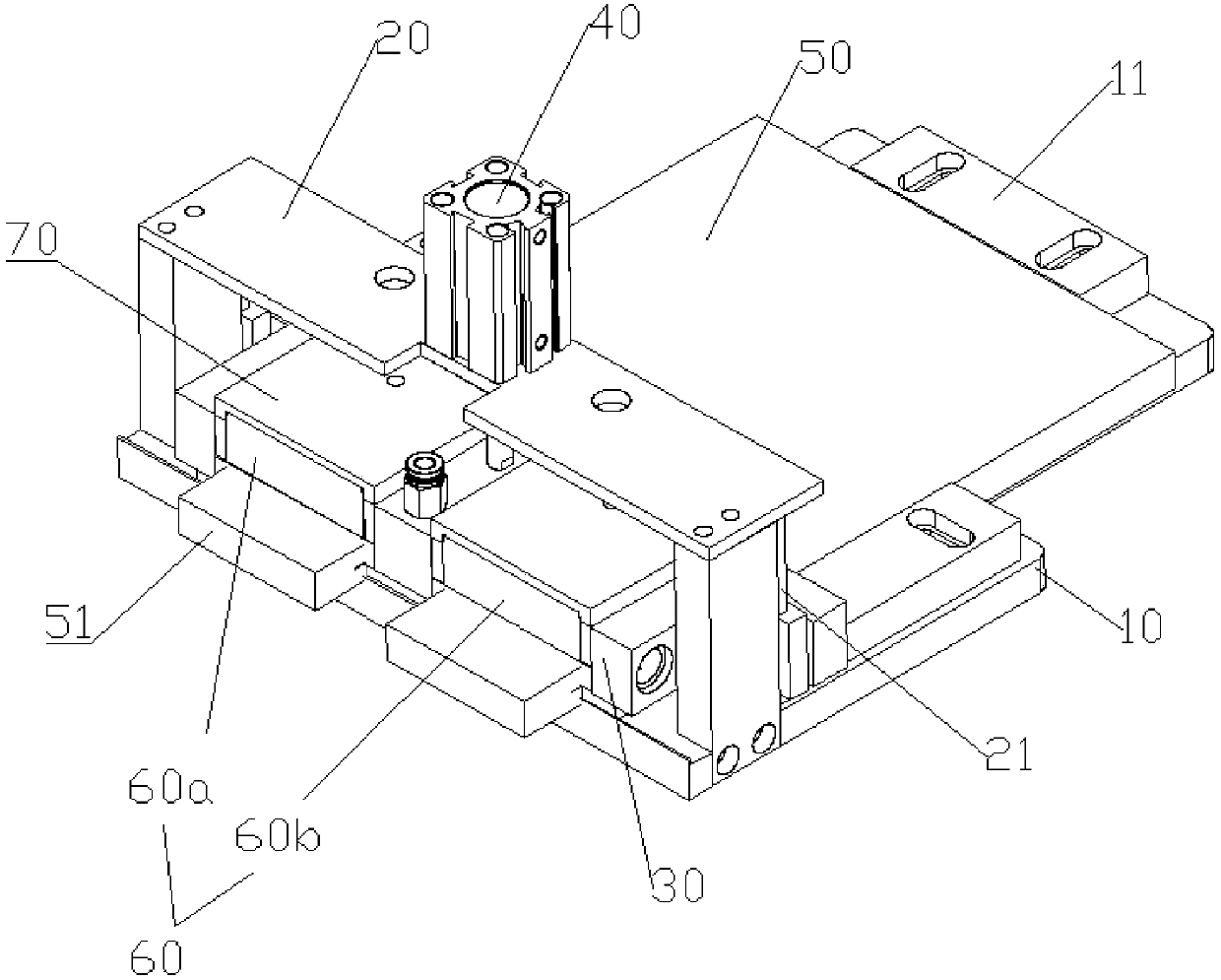

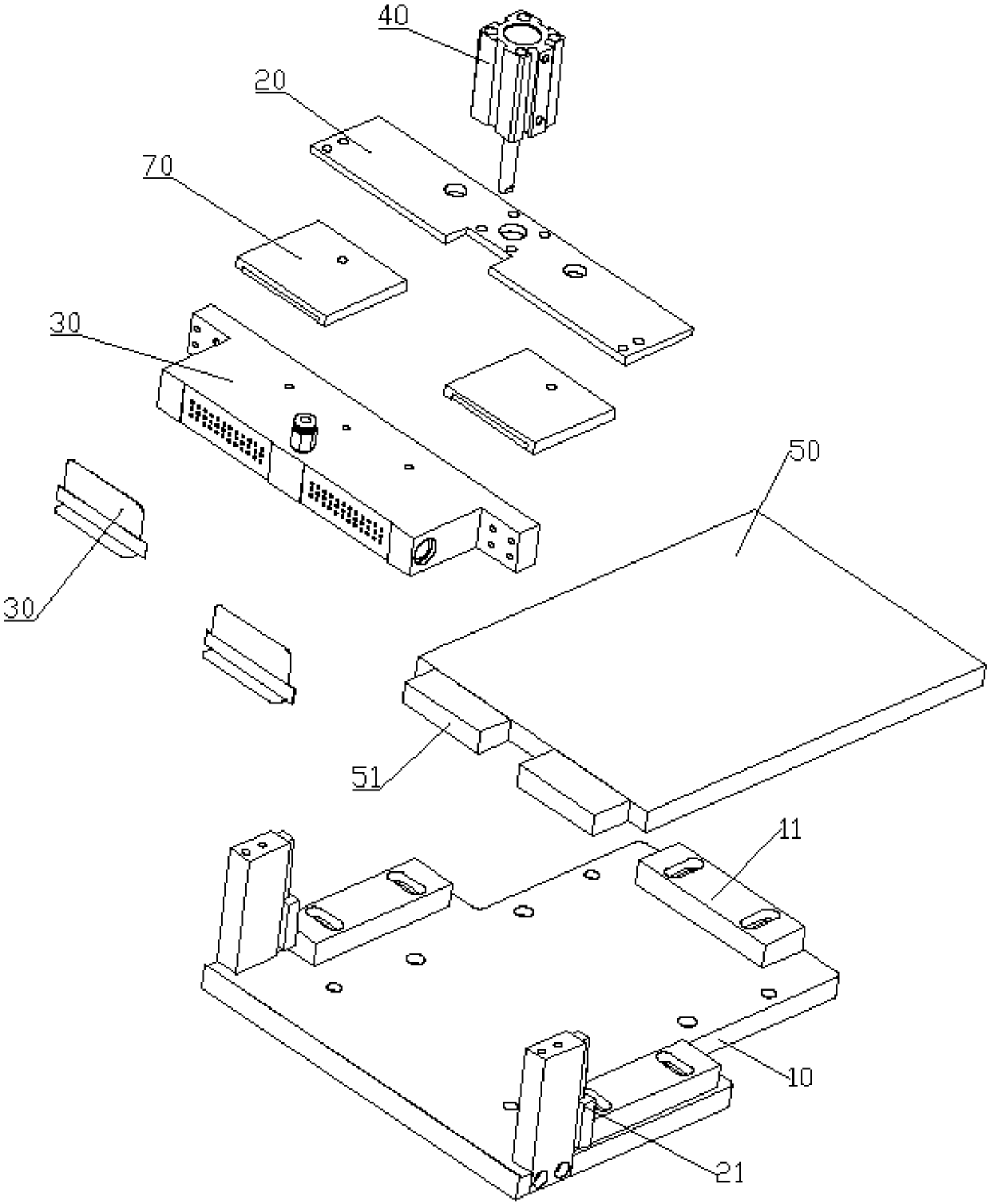

[0058] Such as Figure 1-2 As shown, a battery tab welding device provided in this embodiment includes: a workbench 10, a frame 20, a vacuum adsorption device 30 and an actuator 40;

[0059] The workbench 10 is used to support the cell 50 of the battery;

[0060] The vacuum adsorption device 30 is arranged on the frame 20 in a liftable manner;

[0061] The actuator 40 is fixedly arranged on the frame 20, and is used to drive the vacuum adsorption device 30 to lift up and down;

[0062] The vacuum adsorption device 30 is used for negative pressure adsorption and fixation of the hard tab 60 (or tab for short);

[0063] The hard tab 60 falls down with the vacuum suction device 30 and abuts against the soft tab 51 (or current collector) of the cell 50 .

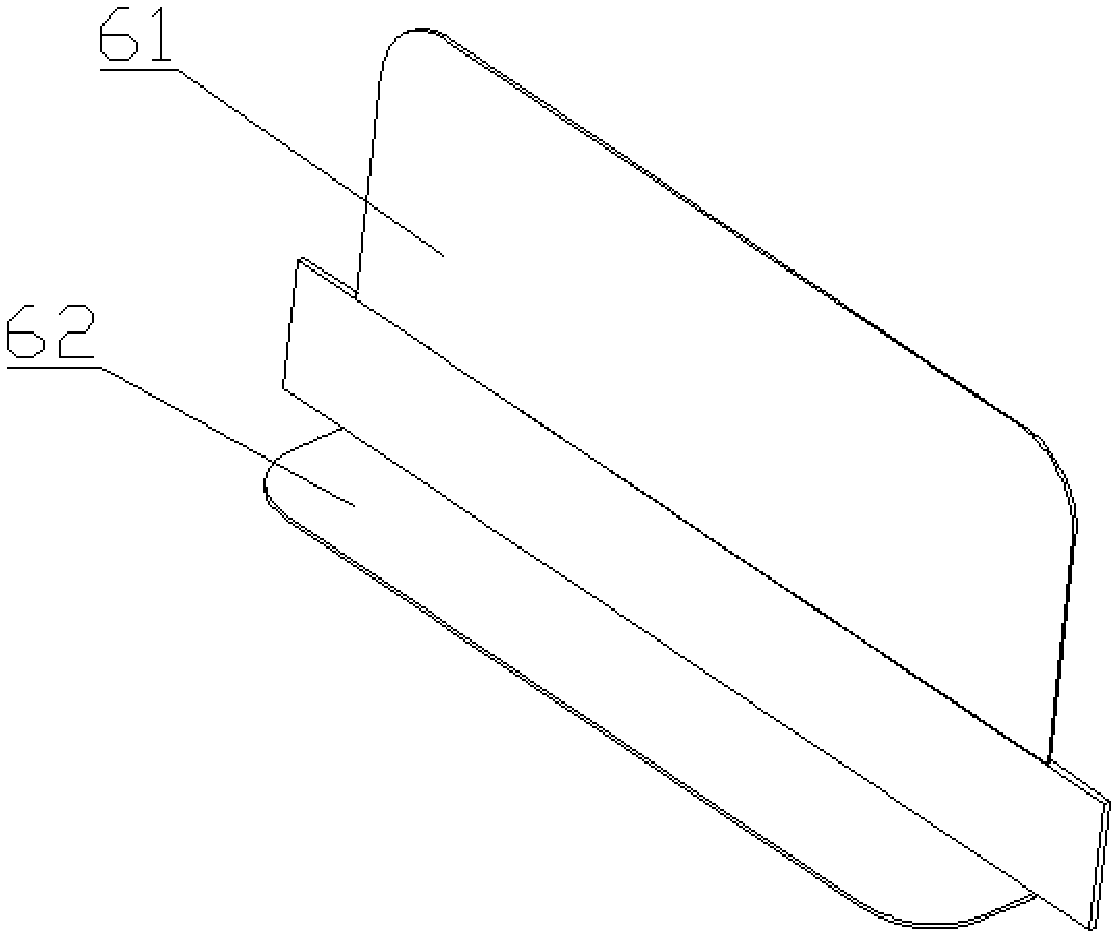

[0064] Among them, the hard tab 60 is usually made of metal thin skin such as copper sheet or aluminum sheet, with a thickness of 0.2-0.5mm, preferably 0.3mm; while the soft tab 51 is made of copper foil, with a thickness of 0...

Embodiment 2

[0087] This embodiment also discloses a welding method using the above-mentioned battery tab welding equipment, wherein reference Figure 1-5 As shown, it includes the following steps:

[0088] S1. Pre-bend the hard lug 60 by 90°;

[0089] S2. Use negative pressure suction and cooperate with the limit mechanism (limit top plate 70) to absorb the bent hard tab 60 under the actuator 40; during the adsorption process, the hard tab 60 is vacuum adsorbed (or negative When pressing and absorbing), the position adjustment in the height and left and right directions is automatically realized;

[0090] S3. Place the cell 50 of the battery on the welding position on the workbench 10; the hard tab 60 corresponds up and down with the soft tab 51 on the cell 50;

[0091] Driven by the actuator 40, the hard tab 60 falls and leans against the soft tab 51, and the two are welded together by ultrasonic waves.

[0092] S4. The negative pressure suction is removed, the hard tab 60 is separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com