Production method for chloropinacoline

A production method and chlorine technology, which are applied in chemical instruments and methods, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve the problems of low product purity and many by-products, and achieve high purity, high product yield, and high production efficiency. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

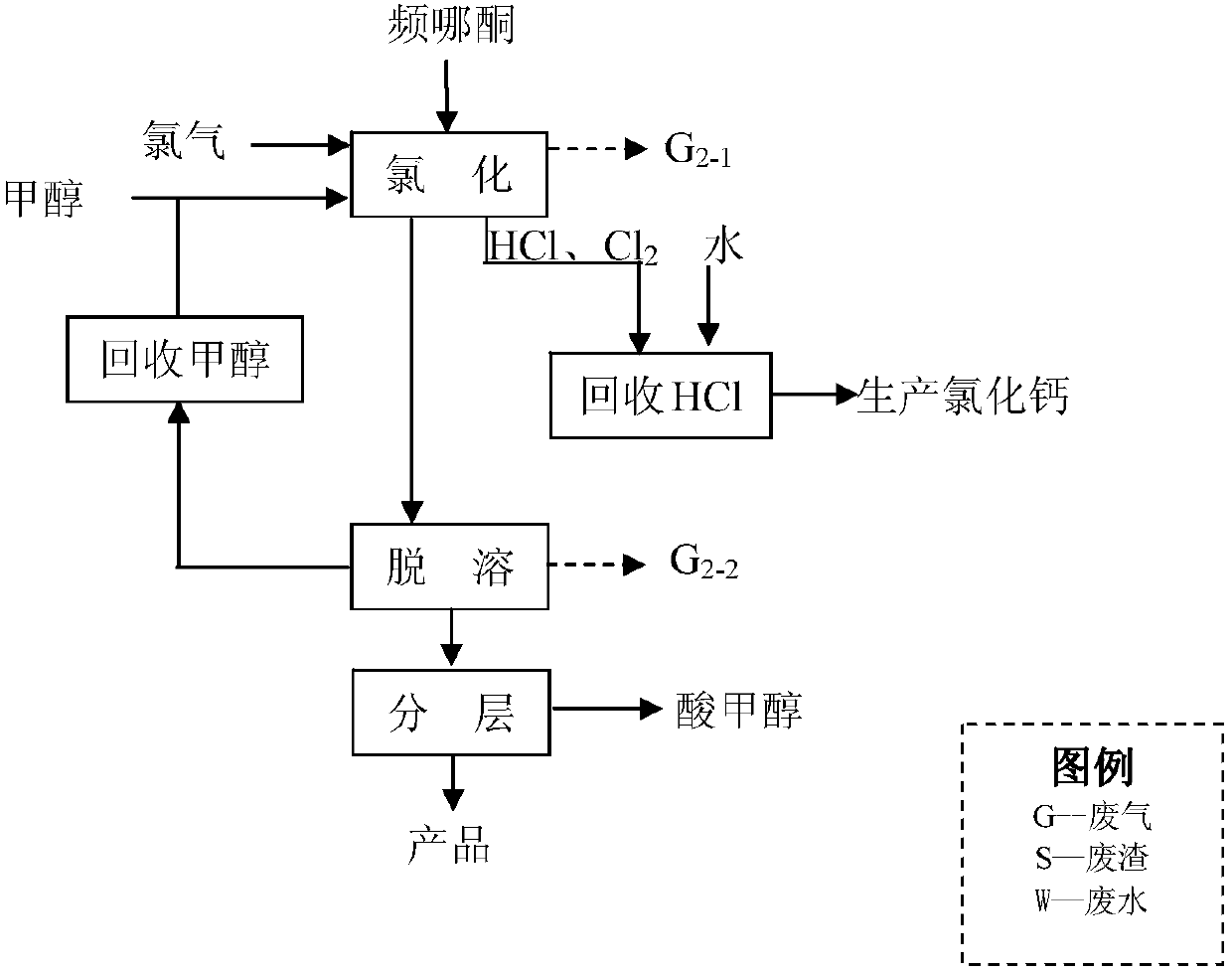

[0015] Present embodiment relates to a kind of production method of chlorpinacolone, such as figure 1 As shown, it specifically includes the following steps:

[0016] 1) Chlorination: The pinacolone produced by the pinacolone production line is pumped into the chlorine reaction kettle, and methanol is introduced as a chlorination reaction catalyst at the same time, the pinacolone is mixed with methanol, cooled with a refrigerated brine jacket for 24 hours, and controlled When the temperature is 0°C, connect the chlorine gas cylinder with the buffer tank with a copper tube, start the reactor to stir, open the valve, and check whether the rotor in the flow meter floats up, check for leakage with ammonia water, and chlorine gas passes through the buffer tank to react with chlorine. After 24 hours of reaction in the kettle, chloropinacolone can be obtained. The construction project is equipped with 4 chlorine reactors, each 2000L, and 4 reactors are operated at the same time. A v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com