Rail bearing complex-blade reciprocating operation multi-unit electricity generating windmill and direction adjusting method

A technology of reciprocating operation and reciprocating blades, applied in the field of power generation windmills, can solve the problems of being easily restricted by site terrain and wasting wind resources, and achieve the effects of no harm caused by flying birds, good power quality, and large wind collection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in detail below. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other implementations obtained by persons of ordinary skill in the art without making creative efforts fall within the protection scope of the present invention.

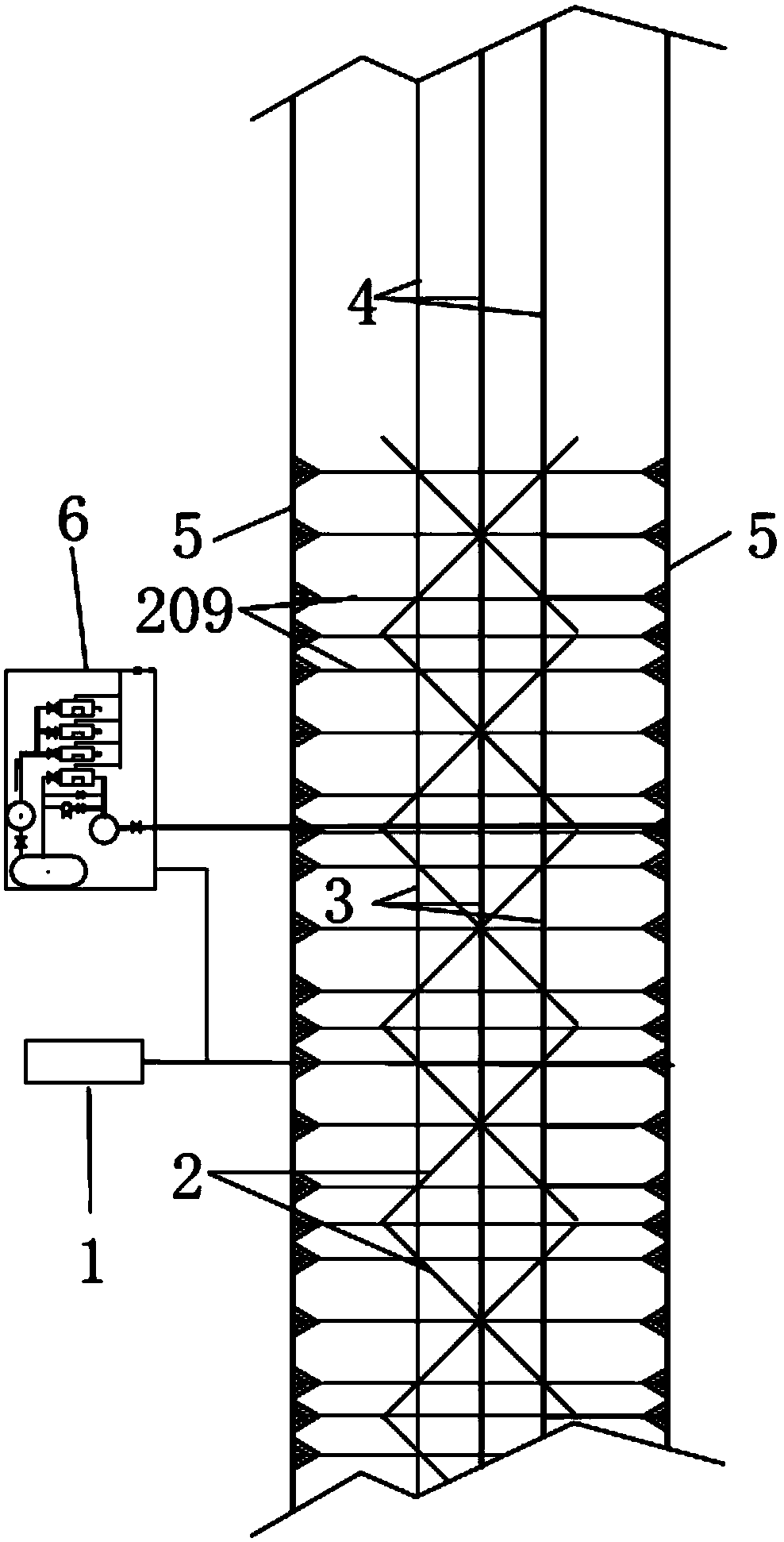

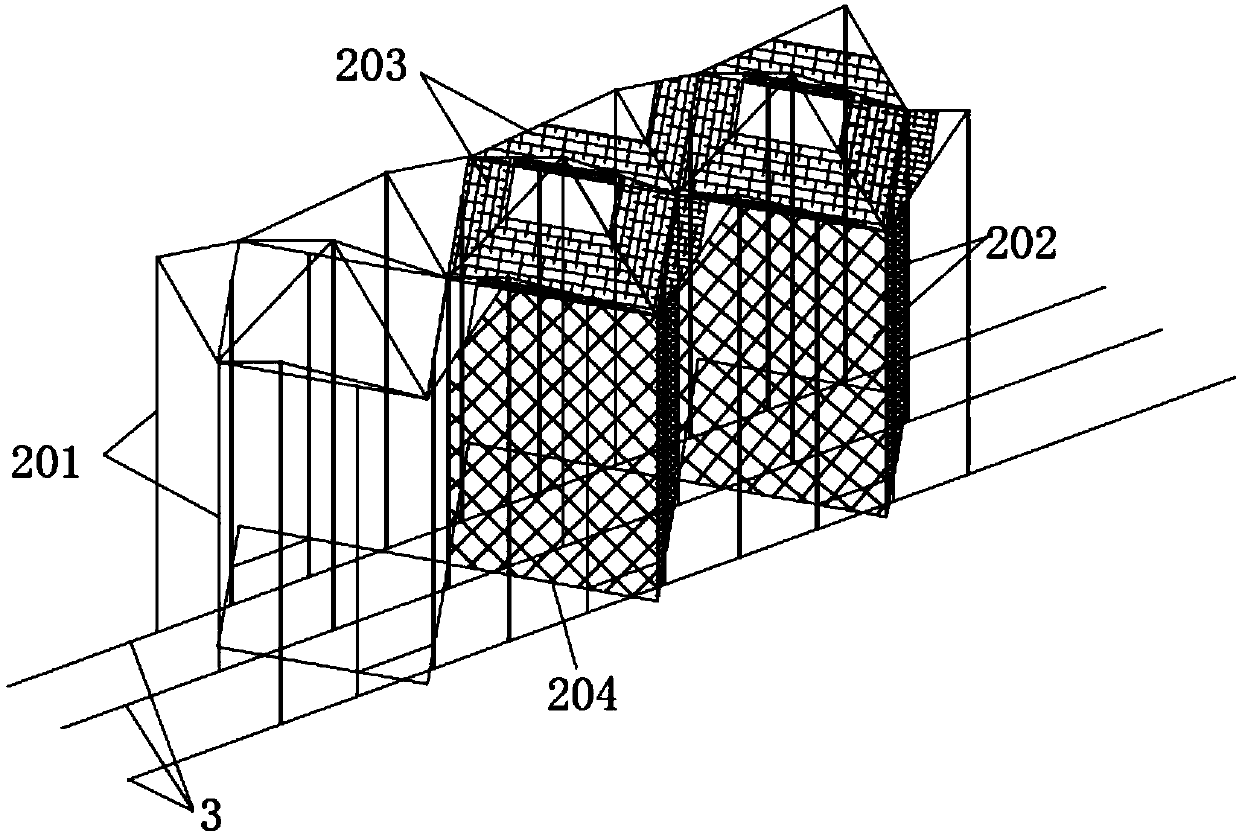

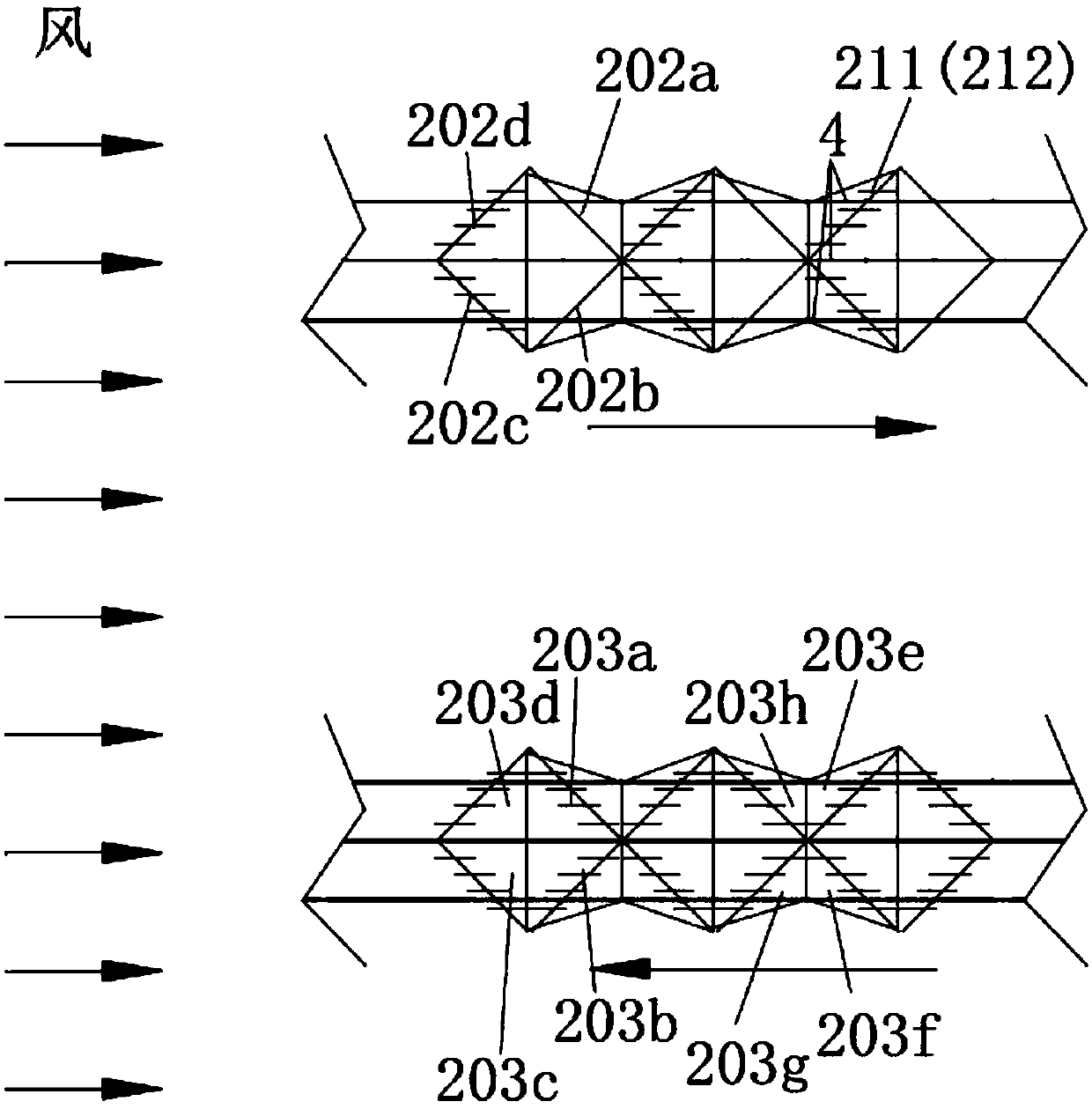

[0048] Such as figure 1 As shown, the rail-carrying compound blades reciprocatingly operate the air pressure energy collection and energy storage multi-unit power generation windmill, including the remote automatic control system 1 of the windmill, the square conjoined compound blade 2 composed of single blades, the windmill body 3 carrying the compound blades, and the support The windmill track 4 that the windmill car body runs, the cable car 5 that runs on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com