Mulberry fruitautomatic collecting and loading device

A technology for automatic fruit collection and fruit collection. It is applied in the fields of picking machines, solid separation, and sieves. It can solve the problems of reduced fruit purity and mixed fruit leaves, so as to ensure normal recovery operations, improve recovery efficiency, and improve the effect of purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

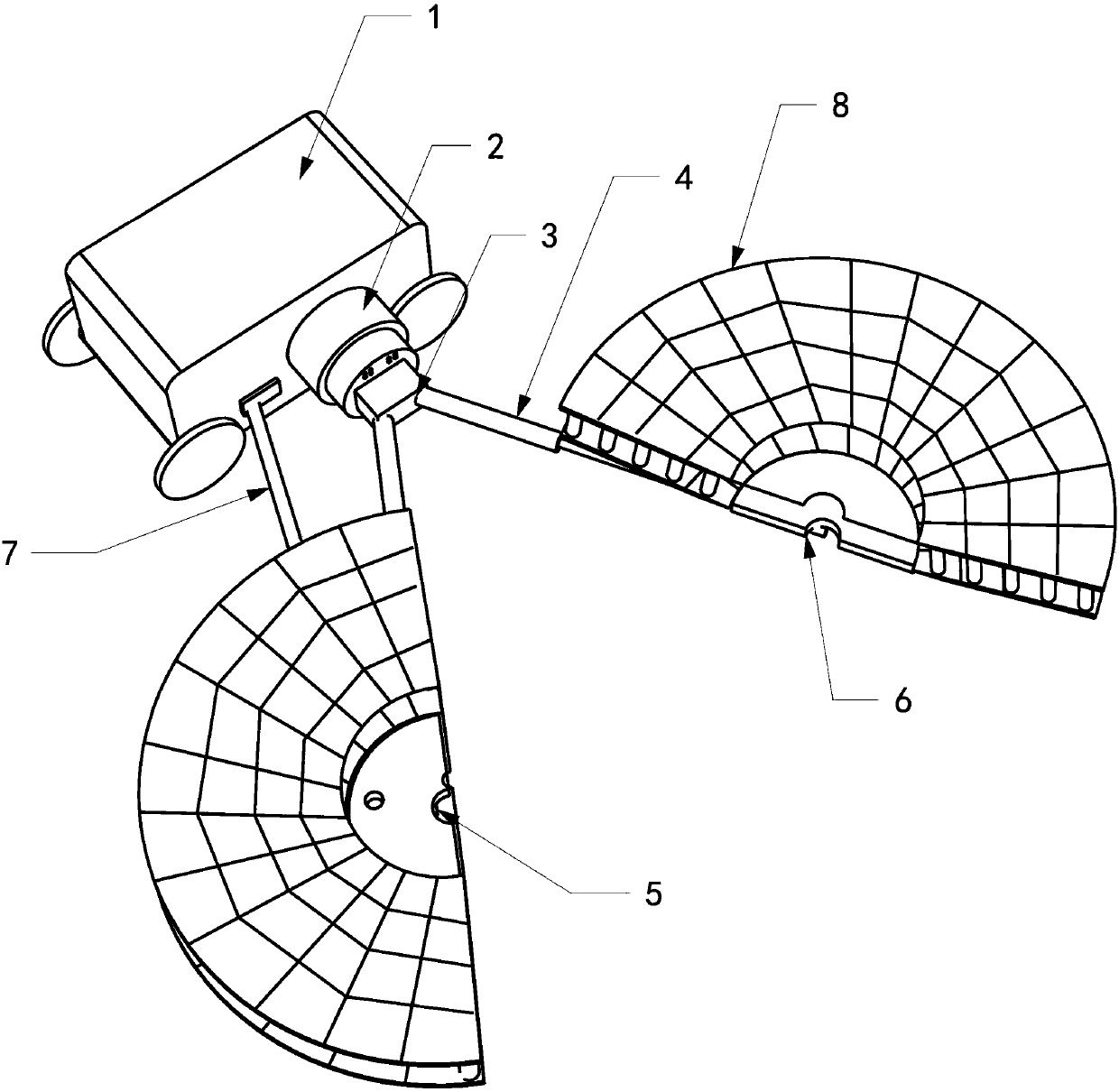

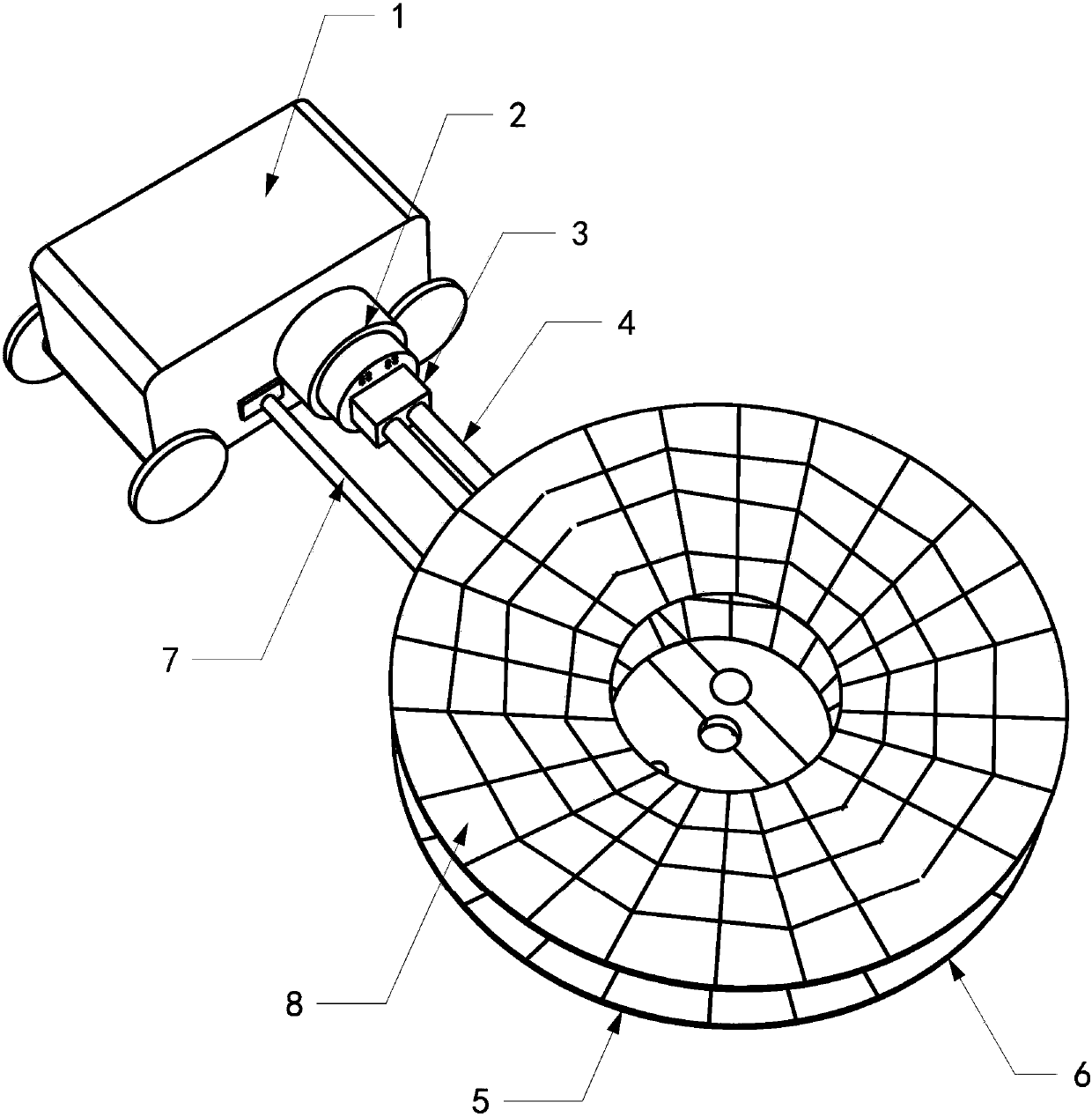

[0029] As shown in the figure, this embodiment provides a kind of automatic collection and packaging equipment for mulberry fruit, including a collection vehicle 1, a vibrating motor 2, a steering controller 3, a telescopic rod 4, and a first semicircular net bag 5 and a second semicircular net pocket 5 that cooperate with each other. Net bag 6, fruit recovery pipe 7 for reclaiming fruit, protective net 8 for preventing leaves from falling into the device, the first semicircle net bag 5 and the second semicircle net bag 6 are connected to the steering controller 3 by telescopic rod 4 respectively , the steering controller 3 is fixed with the vibrating motor 2, the vibrating motor 2 is installed on the side wall of the collection vehicle 1, the inner wall of the fruit recovery pipe 7 is smooth, and one end of the fruit recovery pipe 7 is connected to the first semicircular net bag 5 The center of the fruit recovery pipe 7 is connected to the center of the collection car 1, and t...

Embodiment 2

[0032] In this embodiment, the following optimizations have been made on the basis of Embodiment 1: the first semicircular net pocket 5 and the second semicircular net pocket 6 of this embodiment are both high on the outside and funnel-shaped on the inside.

[0033] The working principle of this embodiment is as follows: when the device is working, the fruit falls into the collection area formed by the closing of the first semicircle net pocket 5 and the second semicircle net pocket 6, and it must enter the middle area before it can be sucked into it by the fruit recovery pipe 7. Temporary storage in the collection car 1, in order to improve the recovery efficiency of the fruit, the present embodiment further designs the first semicircle net pocket 5 and the second semicircle net pocket 6 to be high on the outside and funnel-shaped at the bottom of the inside, which improves the concentration of the fruit to the central area. Probability, improve recovery efficiency.

Embodiment 3

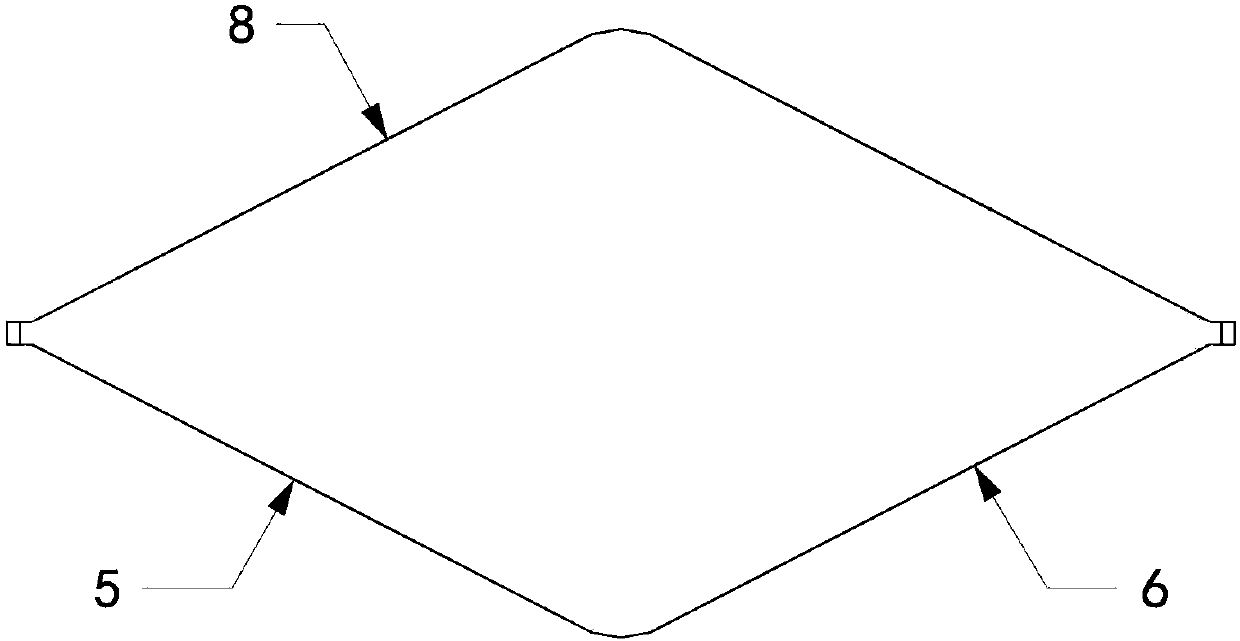

[0035]In this embodiment, the following optimizations are made on the basis of Embodiment 1: the protection net 8 of this embodiment is in the shape of a circular frustum with a low outside and a high inside. After the leaves are isolated by the protective net 8, they are easy to accumulate on the upper surface of the protective net 8, blocking the protective mesh and affecting the collection of fruits. In order to make the leaves easy to separate, the device designs the protective net 8 as a circular platform with a low outer side and a higher inner side. shape, opposite to the direction of inclination of the first semicircle net bag 5 and the second semicircle net bag 6, after setting like this, the leaves will fall to the ground along the slope of the protective net 8 under the action of gravity and vibration force, so as not to Interference is caused to the through hole of the protective net 8, thereby ensuring the normal recovery operation of the fruit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com