Chicken sausage pill and preparation method thereof

A technology of chicken sausage and chicken breast, which is applied in the direction of food science, etc., can solve the problem of not being able to fully retain the original flavor, and achieve the effect of full mouthfeel, mellow mouthfeel, and refreshing aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: The chicken sausage balls of the present invention include the following components: 2 parts of collagen casing and 40 parts of chicken breast filled in collagen casing, 30 parts of chicken meat, 10 parts of chicken skin, 5 parts of soy protein, 10 parts of starch , 10 parts of ice water, 8 parts of seasonings (salt, sugar and MSG), 1 part of food additives (carrageenan, beet red, D-sodium erythorbate and special flavor), 0.5 parts of food flavor (high power meat essential oil), Spices (white pepper powder and Jiawei meat extract powder) 1 part by weight.

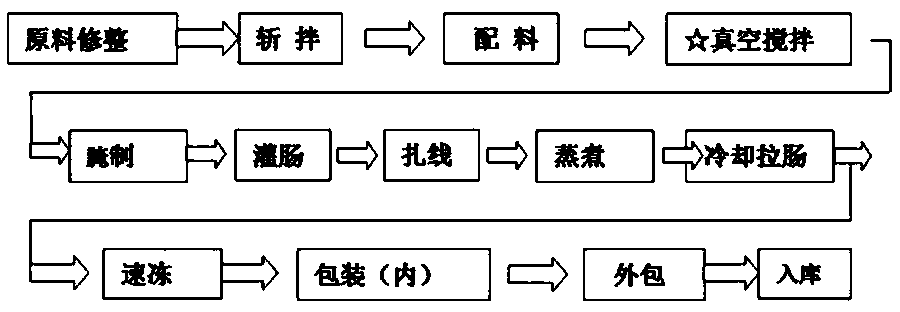

[0024] The preparation method includes the following steps, as shown in Figure 1:

[0025] (1) Chopping and ingredients: take out the meat and poultry provided by qualified suppliers stored in the raw material cold storage, remove the inner and outer packaging of the raw materials and check whether there are sundries on the surface, and then sort them on the shelf to thaw for use. Then turn on the power of the...

Embodiment 2

[0034] Example 2: The components and preparation methods of the product in this example are the same as those in Example 1. The difference is that the contents of each component are: 5 parts of collagen casing and 50 parts of chicken breast filled in collagen casing, chicken 40 parts puree, 20 parts chicken skin, 8 parts soy protein, 20 parts starch, 20 parts ice water, 10 parts seasonings (salt, sugar and monosodium glutamate), food additives (carrageenan, beet red, sodium D-isoascorbate and special Fresh flavor) 3 parts, food flavor (high-powered meat essential oil) 1 part, spices (white pepper powder and Jiawei meat essence powder) 3 parts, by weight.

Embodiment 3

[0035] Example 3: The components and preparation methods of the product in this example are the same as those in Example 1. The difference is that the contents of each component are: 3 parts of collagen casing and 45 parts of chicken breast meat filled in collagen casing, chicken 35 parts puree, 15 parts chicken skin, 6 parts soy protein, 15 parts starch, 15 parts ice water, 9 parts seasonings (salt, sugar and monosodium glutamate), food additives (carrageenan, beet red, sodium D-isoascorbate and special Fresh flavor) 2 parts, edible flavor (high power meat essential oil) 0.8 parts, spices (white pepper powder and Jiawei meat essence powder) 2 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com