Preparation method of fermented chili

A technology of bad peppers and equipment, which is applied in the field of preparation of bad peppers, can solve the problems of easy rancidity of appetizers, difficulty in application, and difficult storage, and achieve the effects of moderate saltiness, reduced processing, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

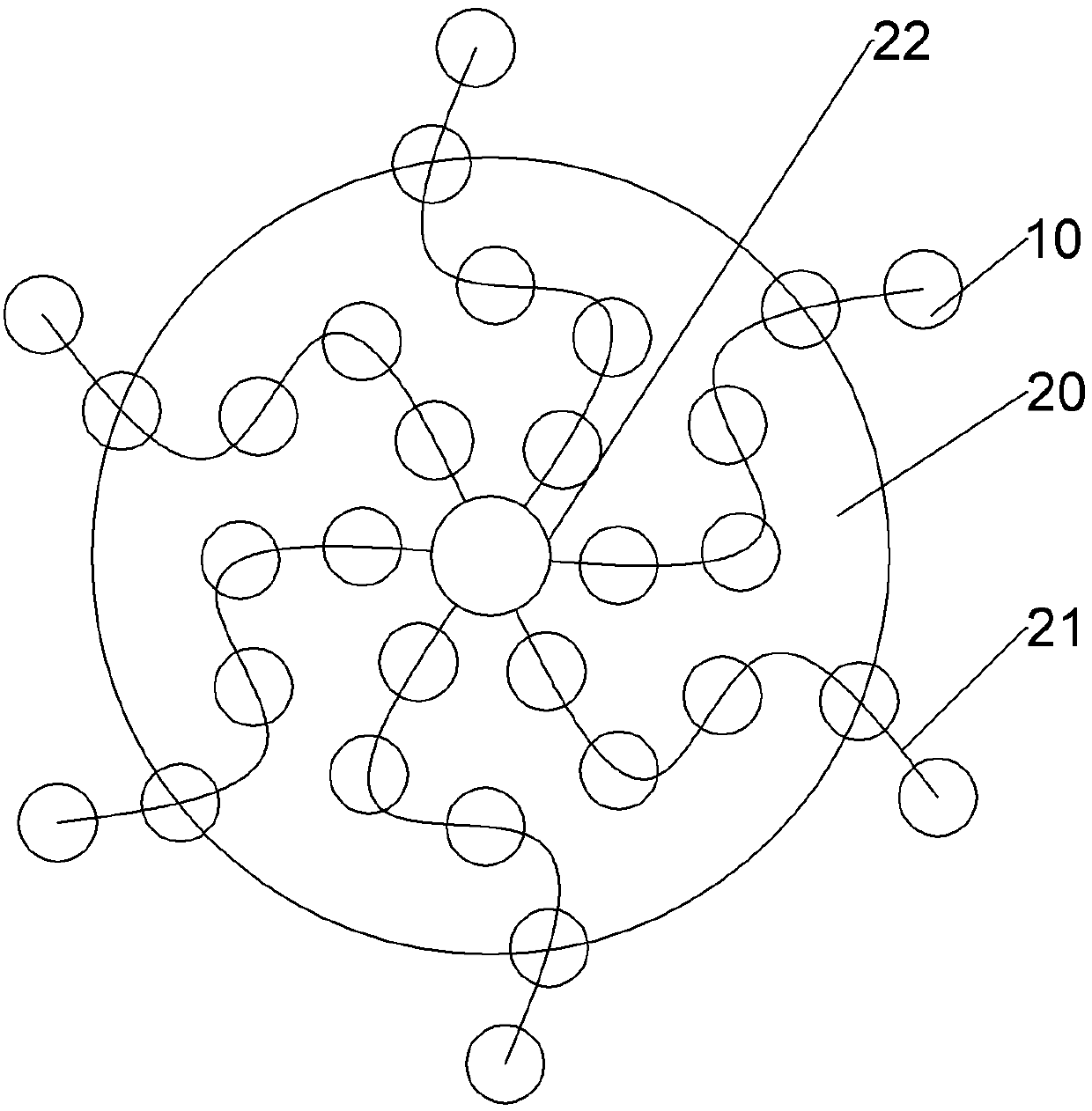

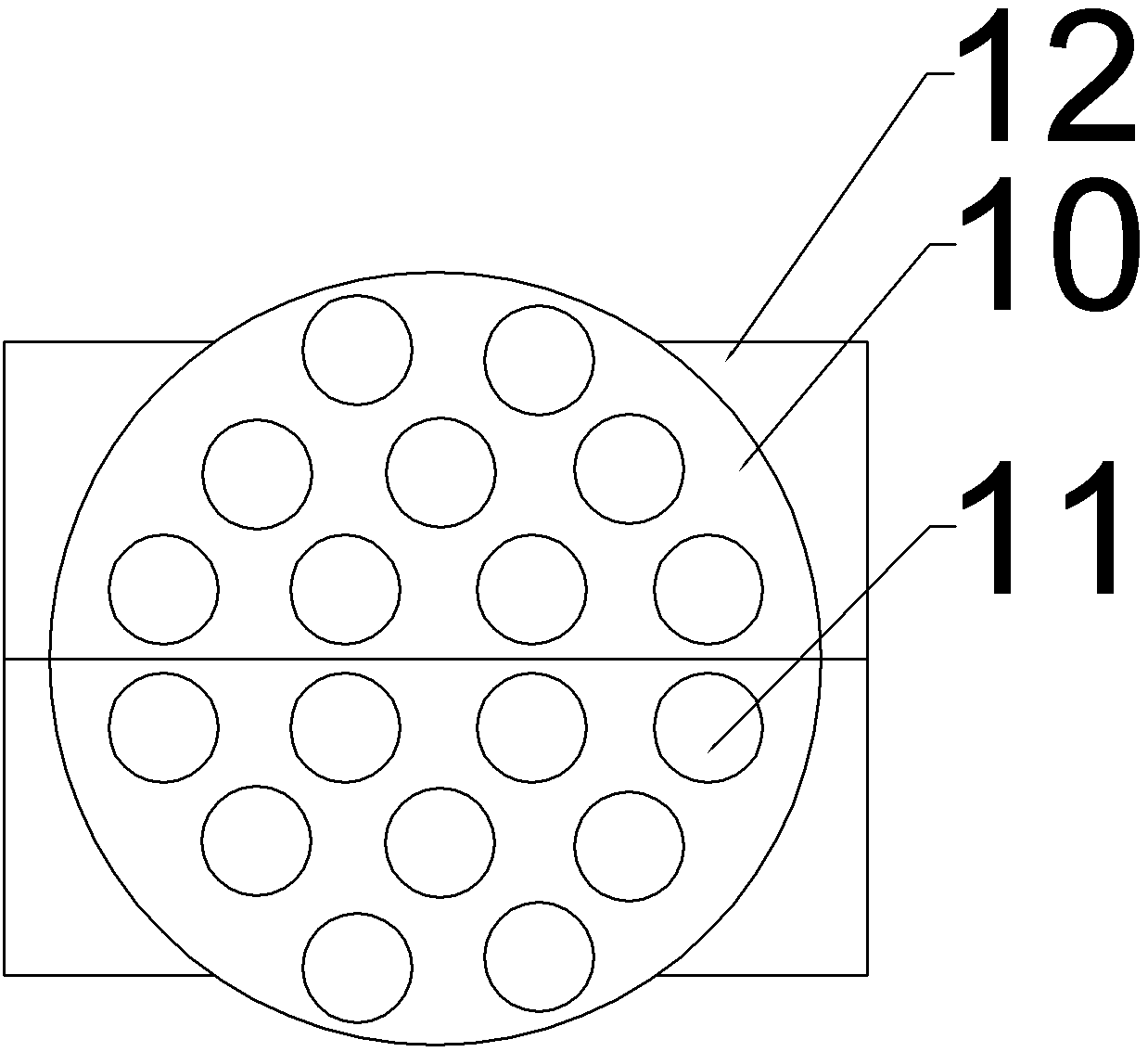

[0019] basically as figure 1 Shown: A device for preparing bad peppers, including a frame, a rotating mechanism and an oil pan arranged in sequence from top to bottom, the rotating mechanism includes a rotating shaft connected to the frame, and two rotating units arranged axially opposite to each other along the rotating shaft The rotating unit includes a turret 21 and a number of rotating shells 10 hemispheres, wherein the turret 21 includes a splined sleeve connected to the rotating shaft and a branch uniformly distributed on the splined sleeve in the circumferential direction, and the rotating shell 10 hemispheres are evenly distributed on the branch, The hemisphere of the rotating shell 10 and the branch are rotatably connected. The hemisphere of the rotating shell 10 of the two rotating units can be fitted, and the spline sleeve and the rotating shaft can be locked by a connecting pin, such as figure 2 As shown, blades 12 are also arranged on the hemisphere of the rotati...

Embodiment 2

[0027] The difference with Embodiment 1 is only:

[0028] The formula of the raw materials is: 20Kg of vegetable oil, 15Kg of pickled pepper, 0.5Kg of pickled ginger, 0.05Kg of old ginger, 0.05Kg of Chinese prickly ash, 3.5Kg of peanut, 0.05Kg of white sesame, 0.1Kg of olive wine, and 0.3Kg of white sugar.

Embodiment 3

[0030] The difference with Embodiment 1 is only:

[0031] The formula of the raw materials is: 22Kg of vegetable oil, 16Kg of pickled pepper, 0.7Kg of pickled ginger, 0.08Kg of old ginger, 0.06Kg of Chinese prickly ash, 3.6Kg of peanut, 0.07Kg of white sesame, 0.13Kg of olive wine, and 0.36Kg of white sugar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com