Protecting device for large sharpening machine grinding wheel blasting piece

A protection device and grinding machine technology, applied in grinding/polishing safety devices, grinding/polishing equipment, metal processing equipment, etc., can solve problems such as increasing equipment failure, damage to grinding machine equipment, and temperature rise. , to achieve the effect of reducing the probability of failure, weakening the degree of damage, and reducing the flight speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

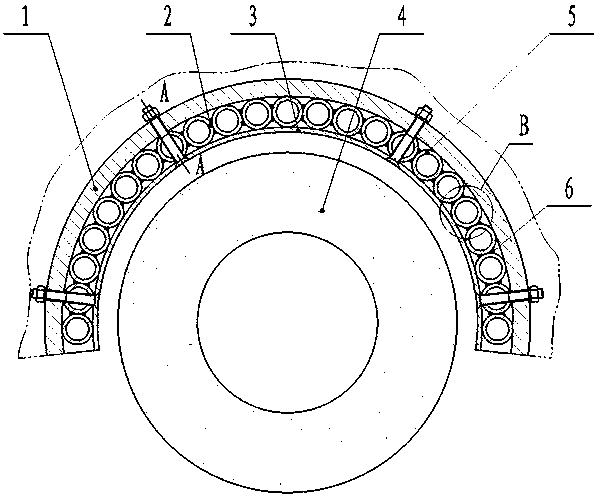

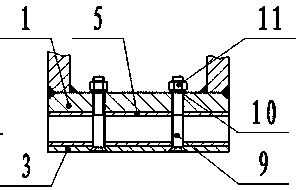

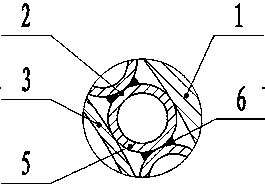

[0018] Such as Figure 1~4 As shown in the figure, a protective device for grinding wheel explosion of a large grinding machine includes a steel pipe group 2, a copper plate 3, and connecting bolts. The inner side of the frame 1 is provided with a steel pipe group 2. The steel pipe group 2 is composed of closely arranged steel pipes 5. The steel pipes 5 are welded to form an arc structure. The inner side of the steel pipe group 2 is provided with a copper plate 3. The frame 1 is fixed by bolts; on the steel pipe group 2, the copper plate 3, and the hanger frame 1, a number of screw holes 7 are evenly arranged along the circumferential direction, and the red copper plate 3, the steel pipe group 2 and the inner wall of the hanger frame 1 are fixed and clamped, Make sure that no relative movement occurs.

[0019] The steel pipe group 2 is attached to the inner wall of the grinder hanger frame 1, and the outer diameter of the arc formed by the steel pipe group 2 is equal to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com