Heterogeneous laminated composite materials and products thereof

A composite material and different material technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve problems such as cost increase and material limitation, achieve weight reduction, low processing cost, good rigidity and the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

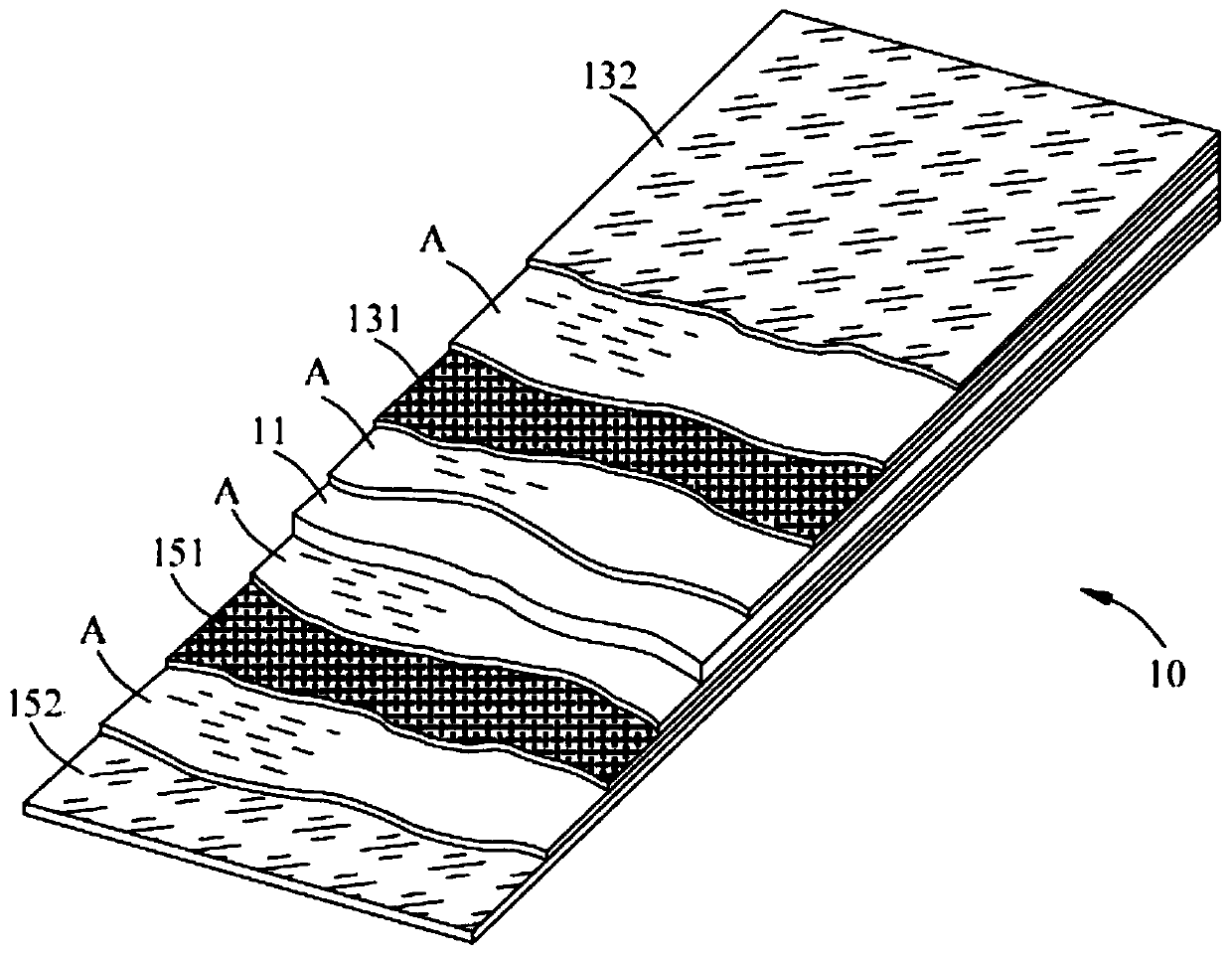

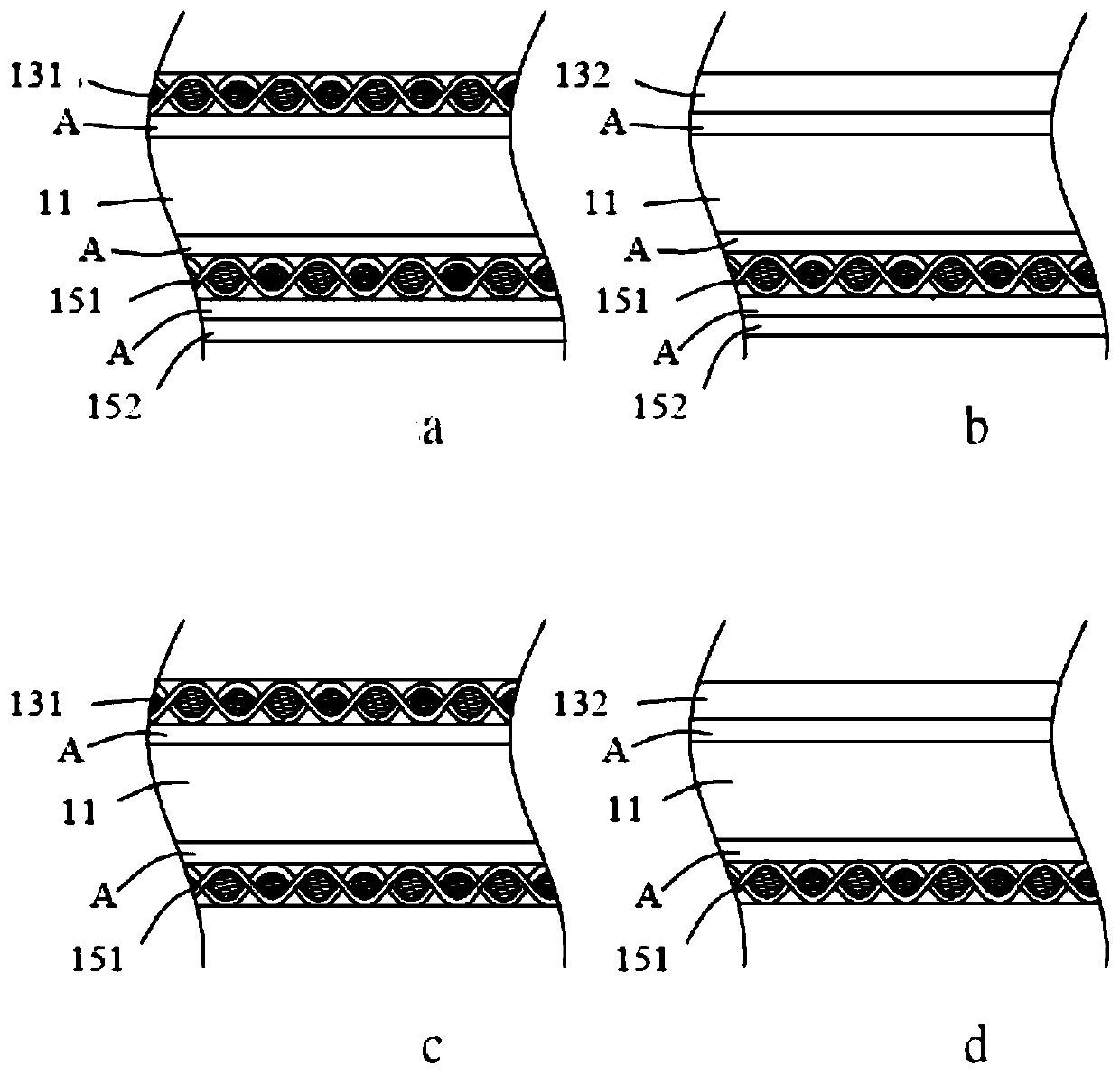

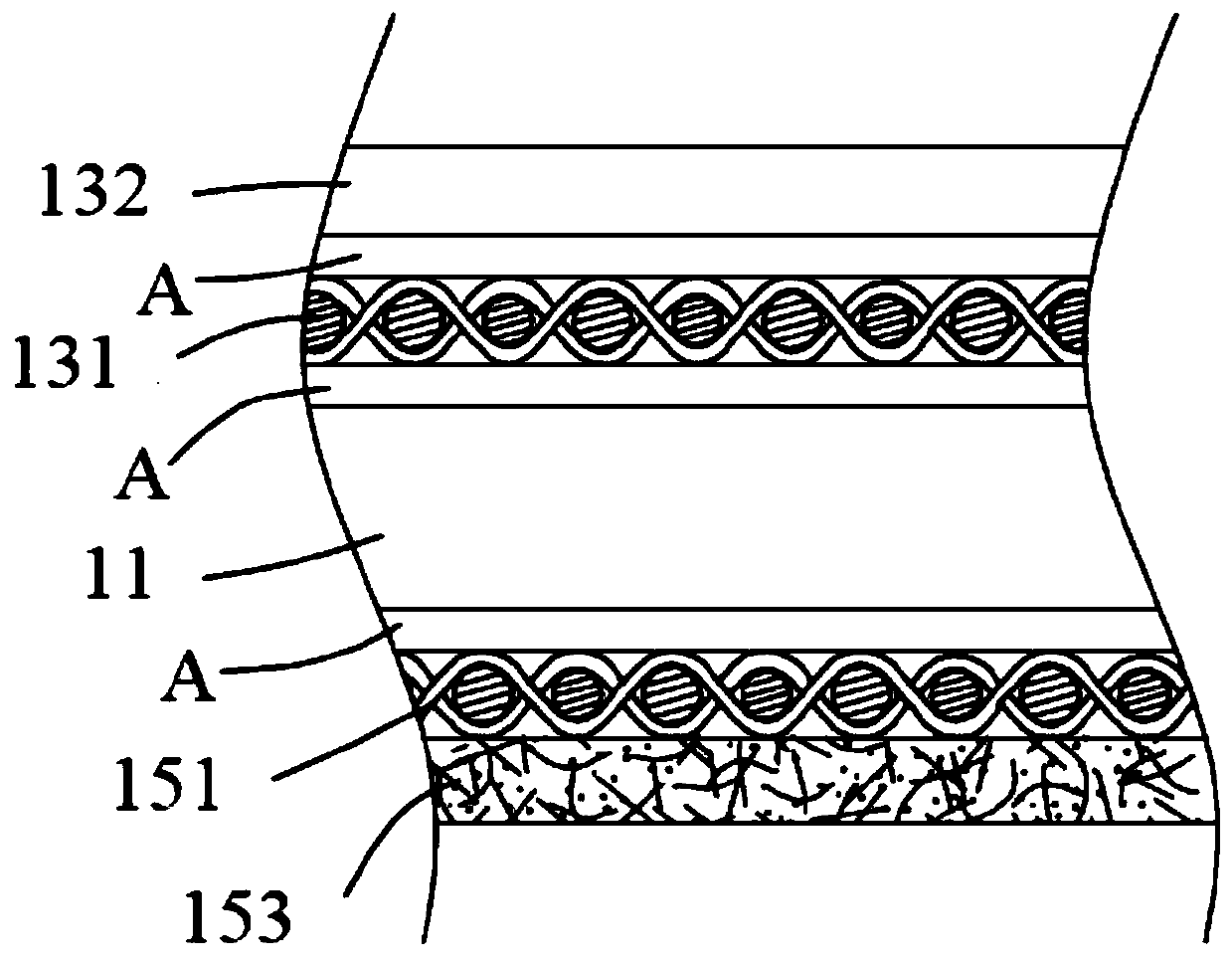

[0036] Please refer to figure 1 The heterogeneous laminated composite material 10 of the first preferred embodiment of the present invention includes a first layer structure 13, a central substrate 11 and a second layer structure 15 stacked in sequence, the first layer structure 13, the second layer An adhesive layer A is respectively provided between the structure 15 and the central substrate 11 for mutual adhesion.

[0037] Wherein, the first layer structure 13 of this embodiment is formed by laminating a first braided fiber layer 131 and a first plastic layer 132, and the first braided fiber layer 131 can not only provide the laminated composite material 10 of different materials with In addition to the appearance of the woven texture, the woven structure has better and more excellent structural strength than ordinary plastic panels. The thickness of the first braided fiber layer 131 in this embodiment is preferably 0.2 mm to 0.5 mm. The material of the first braided fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com