Discharge tube for ozone generator and manufacturing technology thereof

A technology of ozone generator and manufacturing process, which is applied in the direction of ozone preparation, discharge method preparation of ozone, oxygen/ozone/oxide/hydroxide, etc., which can solve the problems of short life, enamel easy to fall off, easy to be damaged, etc., to achieve Effects of high yield, improved equipment stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

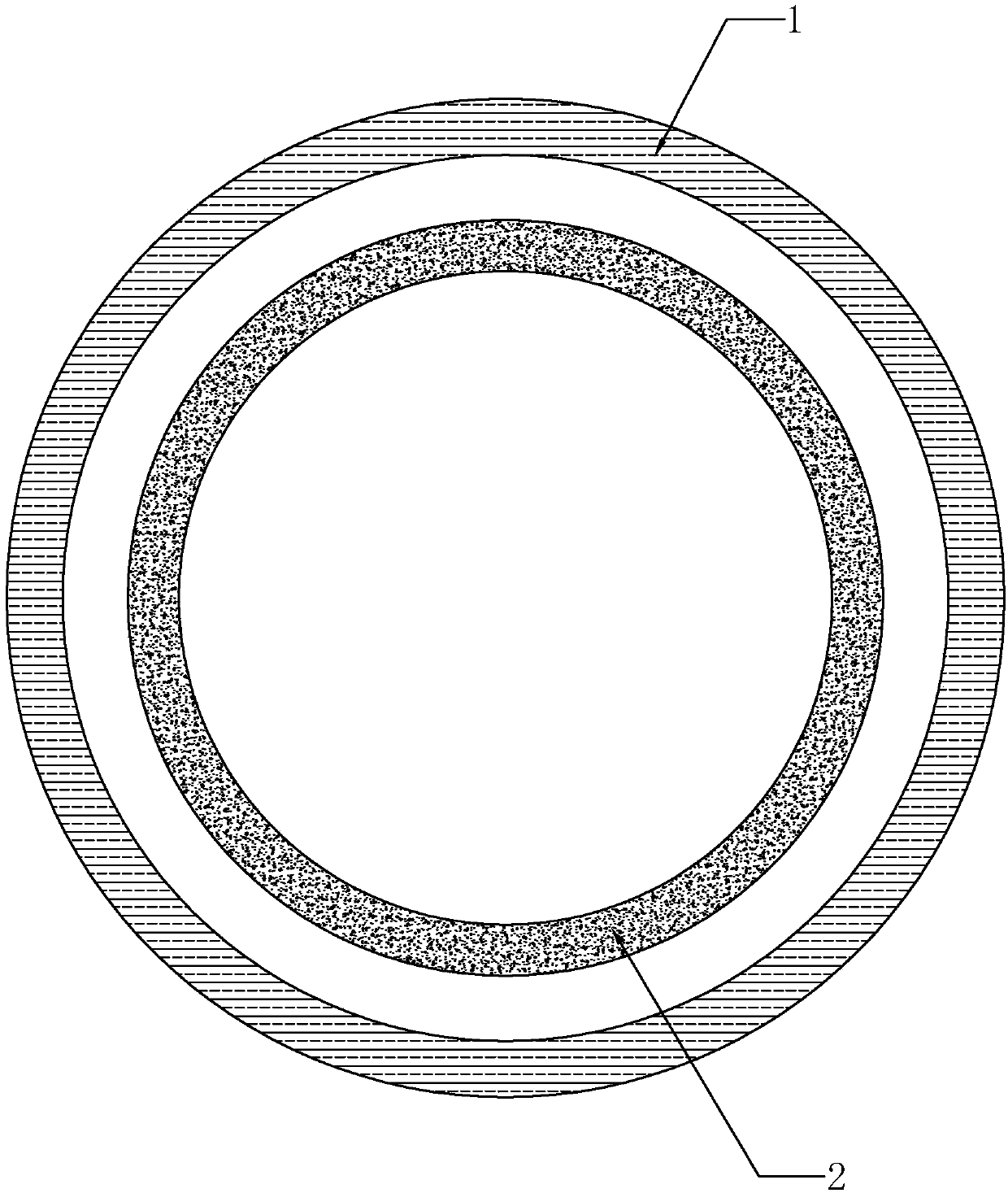

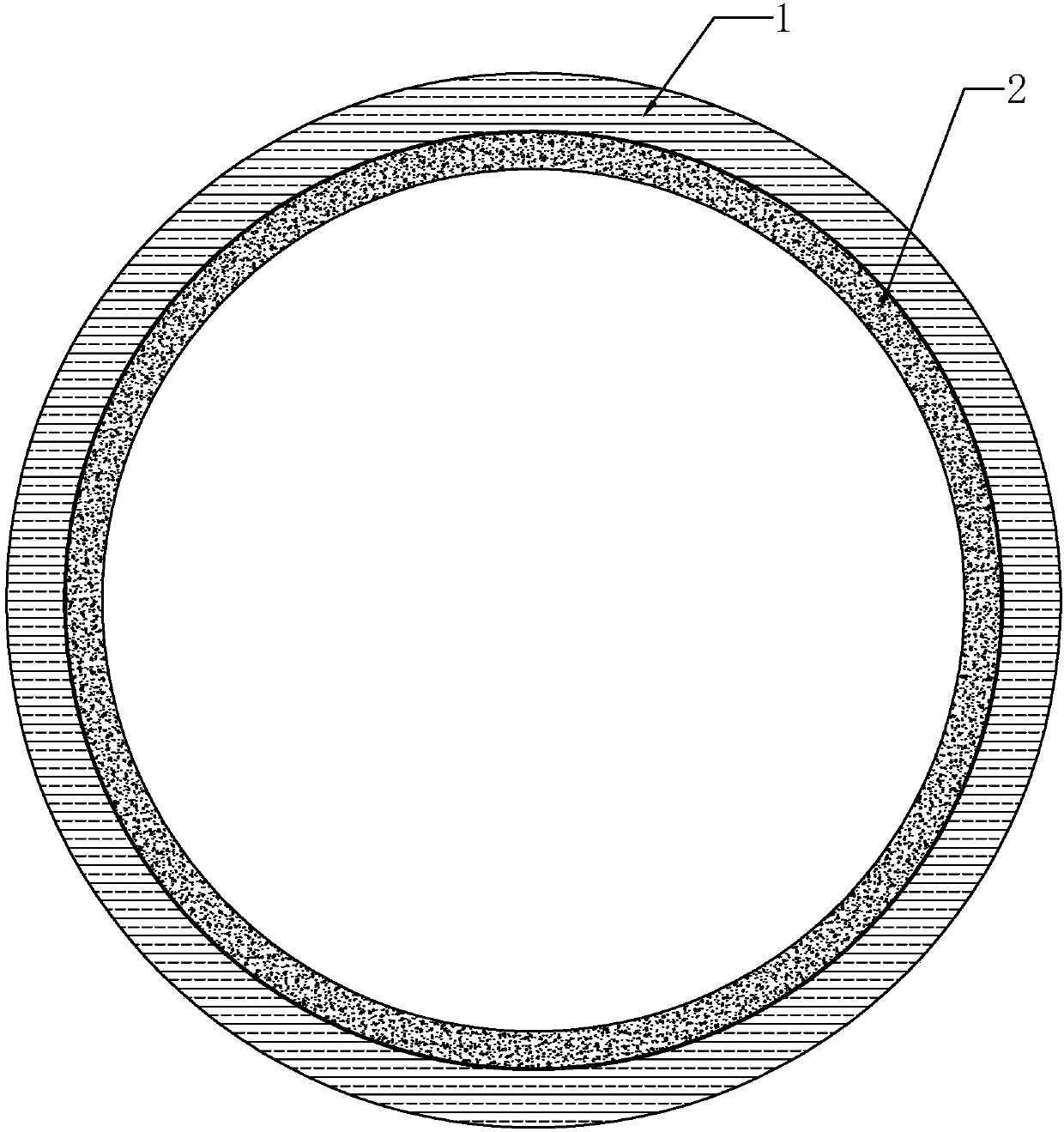

[0017] pass Figure 1 to Figure 2 The discharge tube for the ozone generator of the present invention and its manufacturing process are further described.

[0018] The discharge tube for ozone generator of the present invention includes a grounding electrode and a medium, and is characterized in that: the grounding electrode is a stainless steel tube, the medium is a glass tube, and the glass tube is lined on the inner wall of the stainless steel tube, and the two pass the following process All-in-one settings.

[0019] Preferably, the expansion coefficient of the glass tube is close to that of the stainless steel tube, and the difference is within 1.2*10^-7mm.

[0020] Discharge tube manufacturing process for ozone generator of the present invention comprises the following steps:

[0021] a) Place the glass tube in the stainless steel tube, and seal one side of the stainless steel tube and the glass tube with a sealing cover so that the gas cannot pass through;

[0022] b)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com