Low-carbon efficient biological liquid fuel and preparation method thereof

A bio-liquid, high-efficiency technology, applied in the preparation of liquid carbon-containing fuels, liquid hydrocarbon mixtures, fuels, etc., can solve the problems of high carbon deposition and low utilization rate, optimize flow performance, reduce carbon deposition, and promote effective conversion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

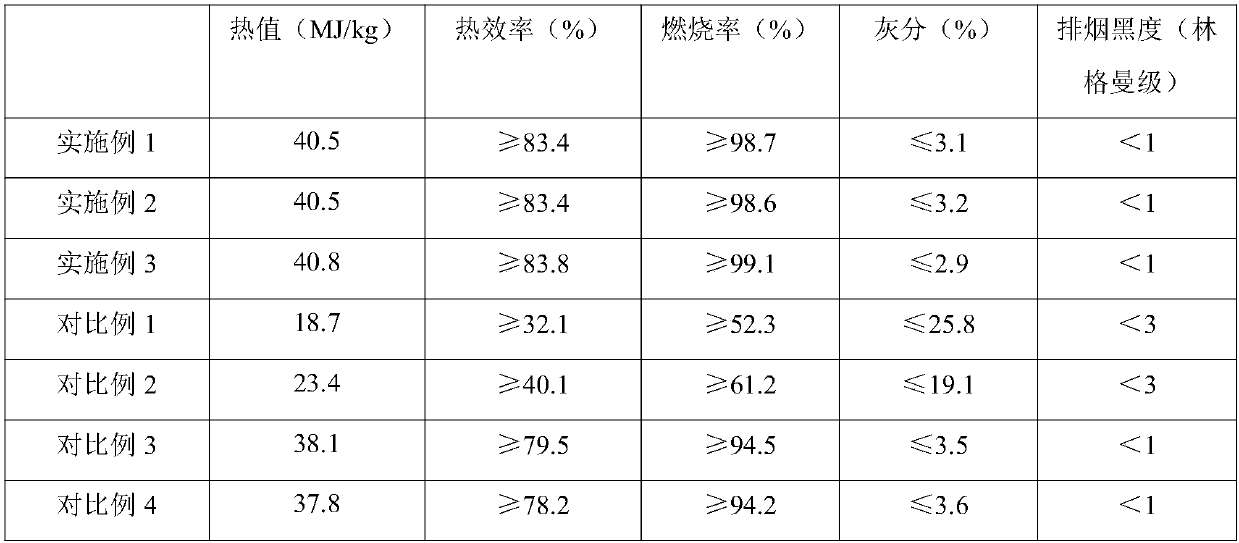

Examples

Embodiment 1

[0030] A method for preparing low-carbon high-efficiency biological liquid fuel, comprising the following steps:

[0031] (1) Drying rice husks, cypress leaves, hemp stalks, tung tree branches and pine cones respectively, pulverizing them and mixing them uniformly to obtain a pulverized mixture for subsequent use;

[0032] (2) putting palm dregs together with α-glucosidase, ligninase, galactose, Micromonospora bronze and water into a fermentation vessel for mixing and stirring, sealed and fermented to obtain a fermented liquid for subsequent use;

[0033] (3) Transfer the pulverized mixture of step (1) to a pyrolysis reactor, carry out a pyrolysis reaction, and collect the condensed liquid, which is biomass pyrolysis liquid;

[0034] (4) Mix the fermented liquid in step (2) with the biomass pyrolyzed liquid in step (3) according to the mass ratio of 1:10, heat to 90° C. and seal and stir for 2 hours to prepare the first mixture and set aside;

[0035] (5) Mix propylene glycol...

Embodiment 2

[0043] A method for preparing low-carbon high-efficiency biological liquid fuel, comprising the following steps:

[0044] (1) Drying rice husks, cypress leaves, hemp stalks, tung tree branches and pine cones respectively, pulverizing them and mixing them uniformly to obtain a pulverized mixture for subsequent use;

[0045] (2) putting palm dregs together with α-glucosidase, ligninase, galactose, Micromonospora bronze and water into a fermentation vessel for mixing and stirring, sealed and fermented to obtain a fermented liquid for subsequent use;

[0046] (3) Transfer the pulverized mixture of step (1) to a pyrolysis reactor, carry out a pyrolysis reaction, and collect the condensed liquid, which is biomass pyrolysis liquid;

[0047] (4) Mix the fermented liquid in step (2) with the biomass pyrolyzed liquid in step (3) according to the mass ratio of 2:10, heat to 100° C. and seal and stir for 3 hours to prepare the first mixture and set aside;

[0048] (5) Mix propylene glyco...

Embodiment 3

[0056] A method for preparing low-carbon high-efficiency biological liquid fuel, comprising the following steps:

[0057] (1) Drying rice husks, cypress leaves, hemp stalks, tung tree branches and pine cones respectively, pulverizing them and mixing them uniformly to obtain a pulverized mixture for subsequent use;

[0058] (2) putting palm dregs together with α-glucosidase, ligninase, galactose, Micromonospora bronze and water into a fermentation vessel for mixing and stirring, sealed and fermented to obtain a fermented liquid for subsequent use;

[0059] (3) Transfer the pulverized mixture of step (1) to a pyrolysis reactor, carry out a pyrolysis reaction, and collect the condensed liquid, which is biomass pyrolysis liquid;

[0060] (4) Mix the fermented liquid in step (2) with the biomass pyrolyzed liquid in step (3) according to the mass ratio of 1.5:10, heat to 95° C. and seal and stir for 2.5 hours to prepare the first mixture and set aside;

[0061] (5) Mixing propylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com