Flushing control method and system for solenoid valves of wet type dual clutch transmission clutch

A wet dual-clutch, solenoid valve technology, applied in clutches, transmission control, components with teeth, etc., can solve the problems affecting the control quality of the solenoid valve, affecting the driving safety, and the solenoid valve sticking, etc., to prevent long-term work. Wear, ensure driving safety, avoid slippage and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

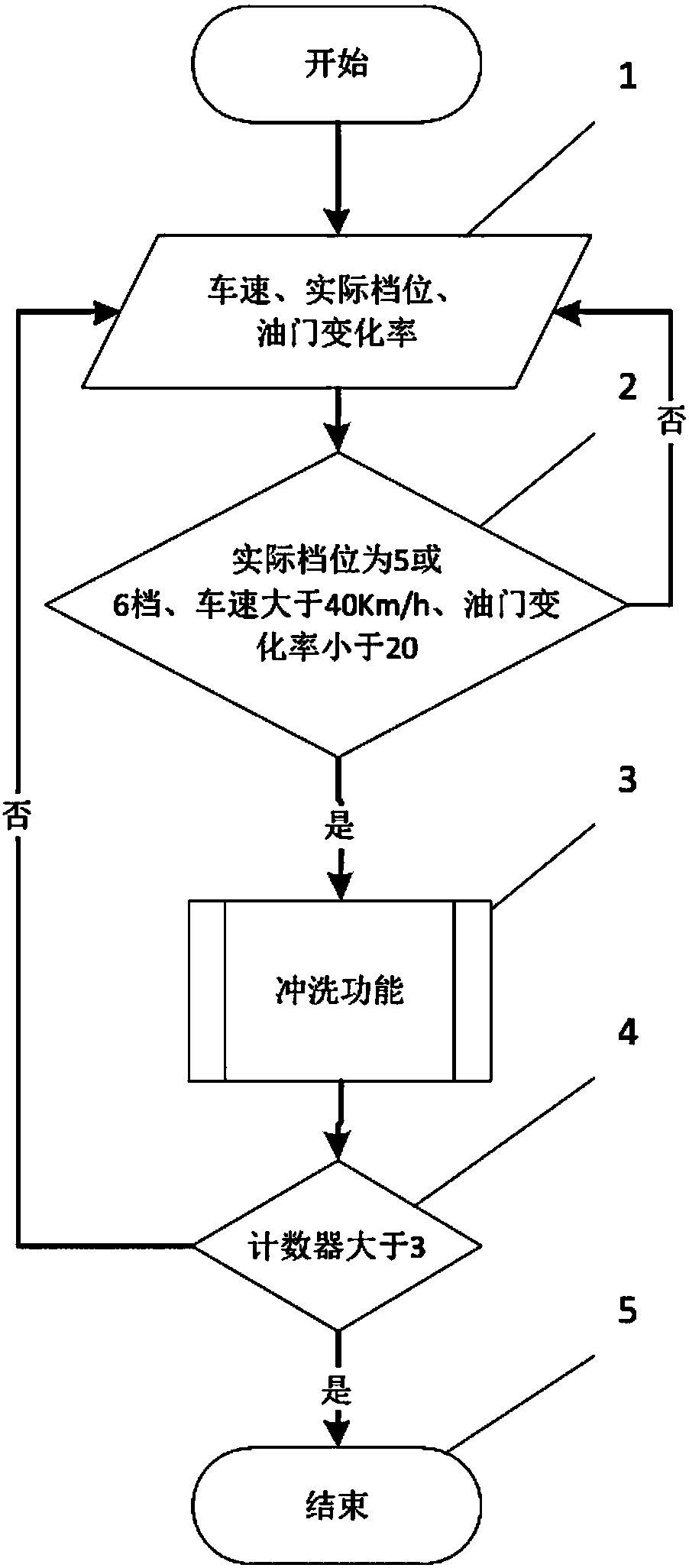

[0051] By detecting the driving state of the vehicle and judging the state in real time: when the vehicle is running normally, pulse flushing is performed on the solenoid valve of the non-working clutch, such as figure 1 shown. When the vehicle speed is greater than 40km / h, the actual gear position is 5th gear or 6th gear, and the throttle change rate is less than 20% (step 2), then enter the automatic flushing function (step 3). Determine the number of flushing cycles in a flushing process (step 4), and exit flushing if it exceeds 3 cycles.

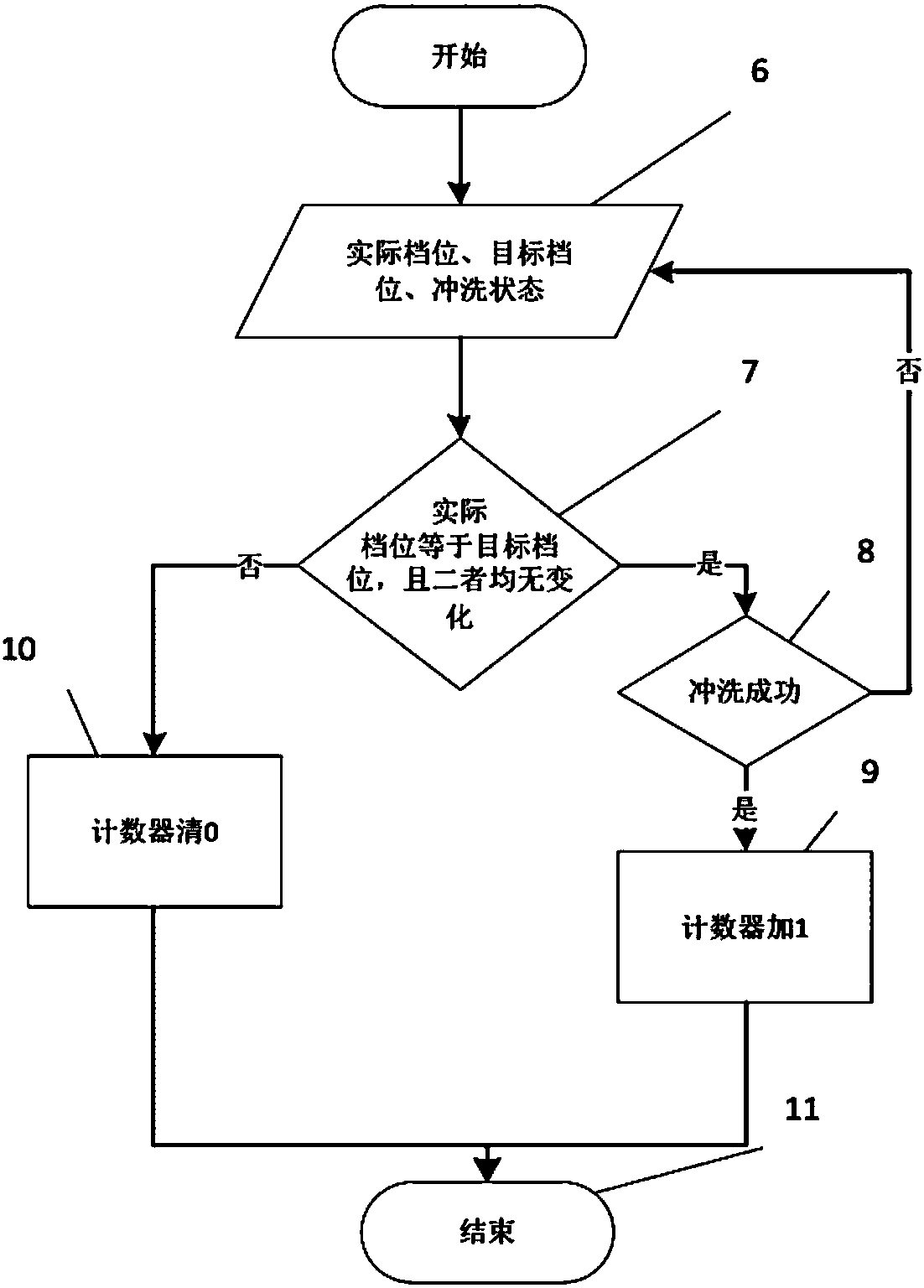

[0052] The judgment of the above-mentioned flushing process is as follows: figure 2 shown. Detect the actual gear and the target gear (step 6), when there is no change (step 7), it is judged to be the same flushing process, and the cycle counter is incremented by 1 after a flushing cycle is completed (step 9), otherwise Then the counter is cleared to 0 (step 10).

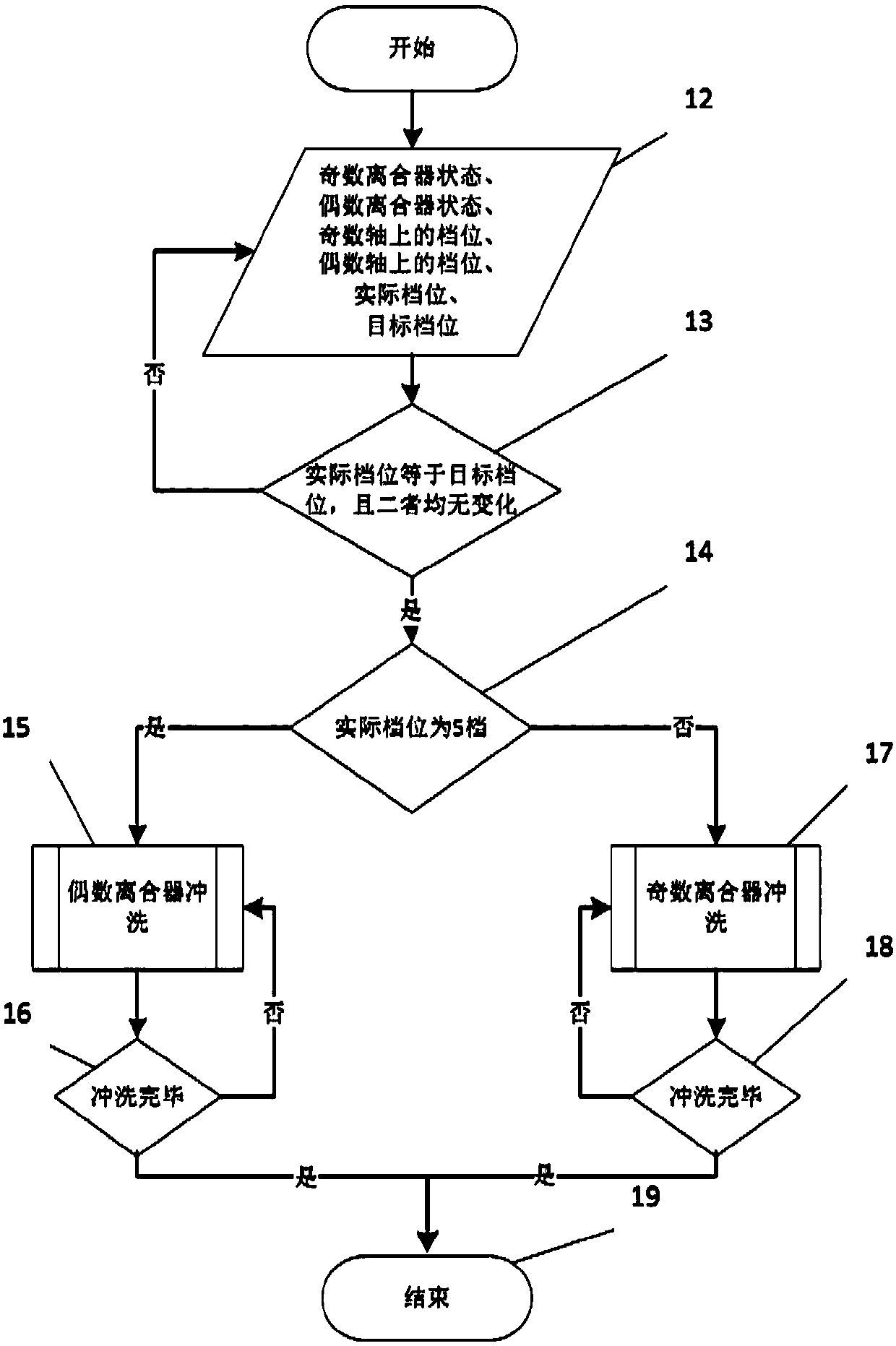

[0053] In the above flushing cycle, the selection of the target sole...

Embodiment 2

[0057] By detecting the driving state of the vehicle and making a real-time state judgment: when the solenoid valve is stuck and reports a pressure difference fault, the vehicle limps or is in a parking state, the faulty clutch solenoid valve is pulsed to be flushed, such as Figure 8 shown. When there is a differential pressure failure in the odd clutches and the transmission utilizes the even gears to limp (the 43rd step), then the odd clutch electromagnetic valve is automatically flushed (the 47th step). When there is a differential pressure failure in the even clutches and the transmission utilizes the odd gears to limp (the 44th step), then the odd clutch electromagnetic valve is automatically flushed (the 45th step). In order to protect the solenoid valve, the flushing cycle is set to 10 (step 50), and when the upper limit is reached, the flushing is completed (step 51).

[0058] In the above flushing cycle, the automatic flushing process of odd-numbered clutch solenoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com