Temperature monitoring system based on fiber Bragg grating sensor

A fiber Bragg and grating sensor technology, applied in the power field, can solve problems such as being susceptible to electromagnetic interference and data loss, and achieve the effects of strong reusability, strong applicability, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

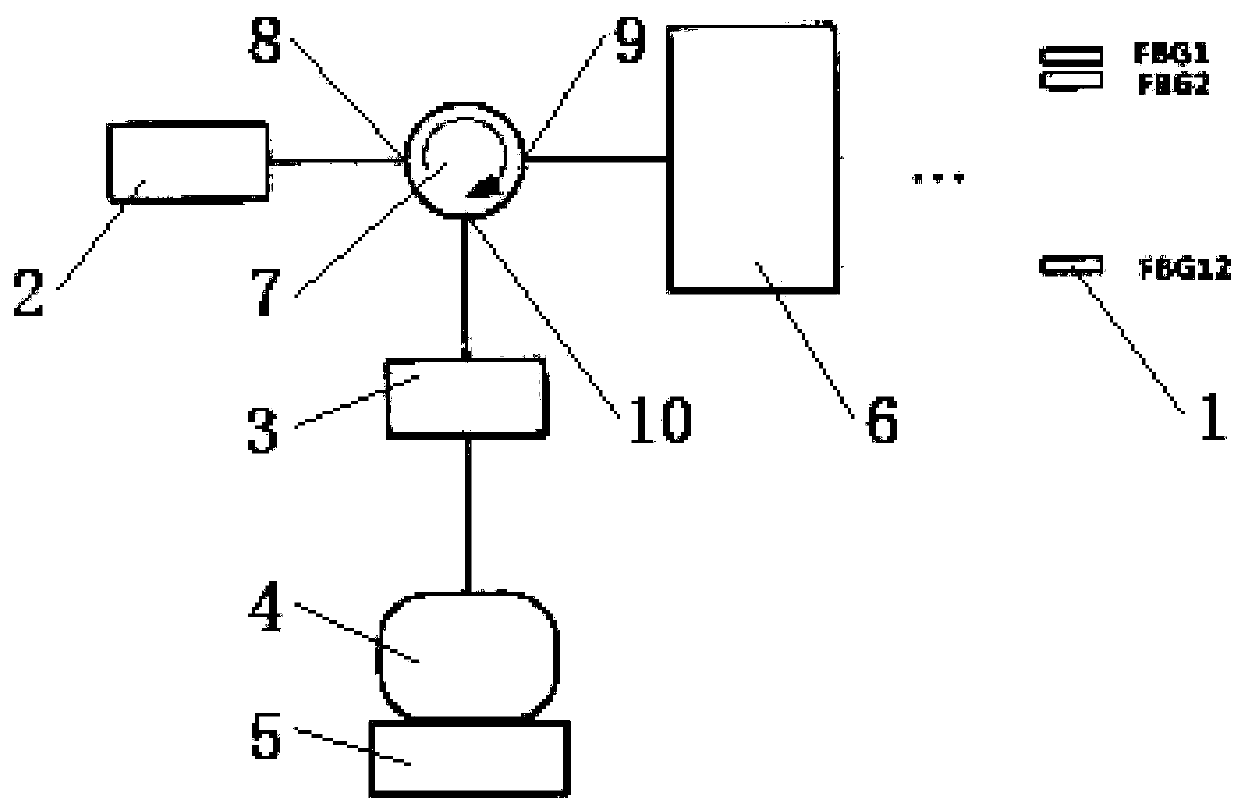

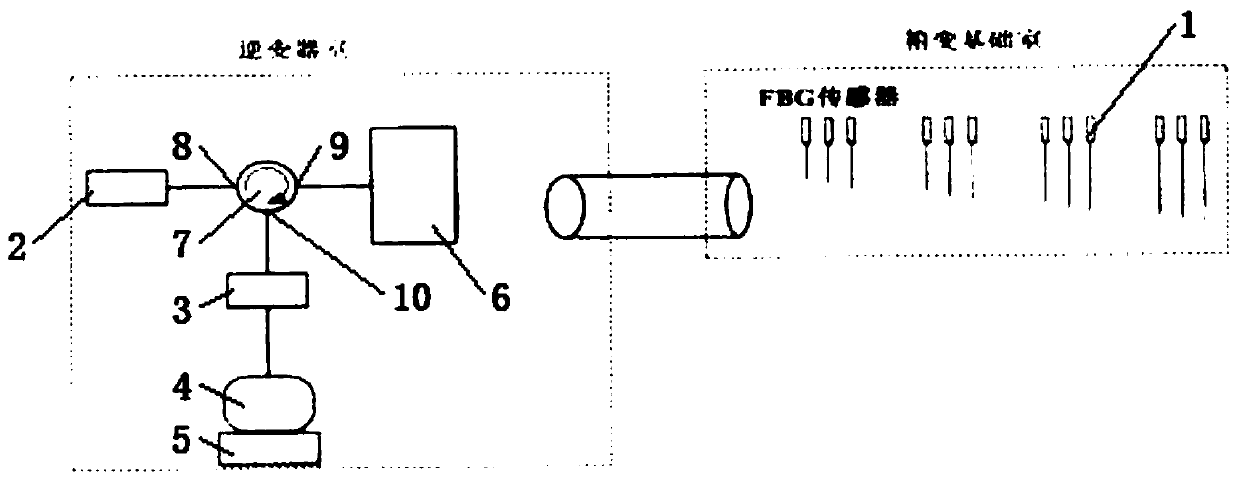

[0031] see figure 1 As shown, the above-mentioned temperature monitoring system based on fiber Bragg grating sensor is used to monitor power equipment. There are generally multiple monitoring points in electric equipment, and multiple fiber Bragg grating sensors 1 are installed at the multiple monitoring points in one-to-one correspondence.

[0032] The temperature monitoring system also includes a light source module 2 for emitting an ASE light source, and a first signal transmission unit for sending the first light wave signal output by the light source module 2 into the fiber Bragg grating sensor 1 .

[0033] Fiber Bragg grating sensor 1 (FBG) is formed by using the ultraviolet photosensitive characteristics of germanium-doped silica fiber and using a special process to make the fiber core undergo a permanent change in the refractive index...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com