Geotextile axial-compression clogging test device and method thereof

A technology of geotextile and axial compression, which is applied in measuring devices, analysis of suspensions and porous materials, scientific instruments, etc., can solve the problems of low labor efficiency, long test time, easy blockage of piezometric tube nozzles, etc., and achieve design Reasonable, simple overall structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

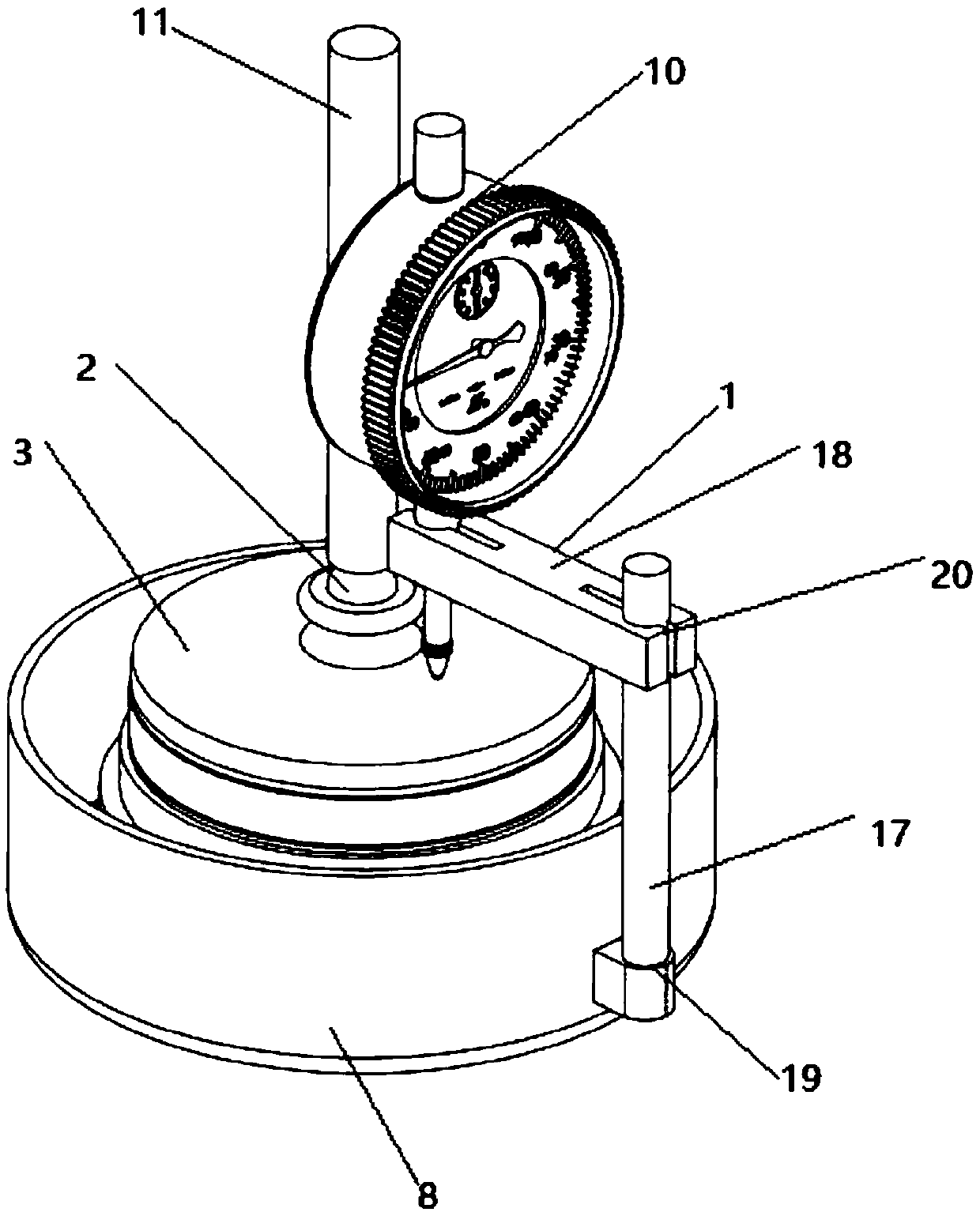

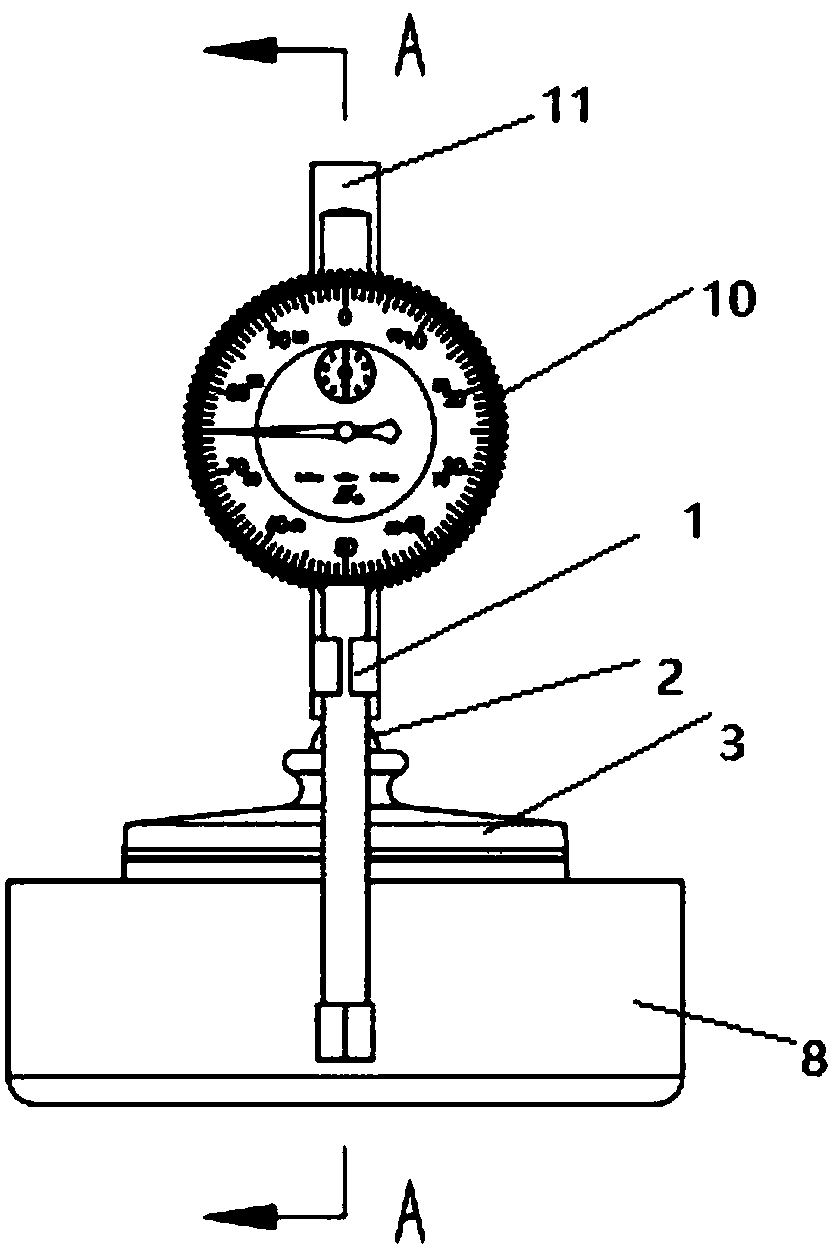

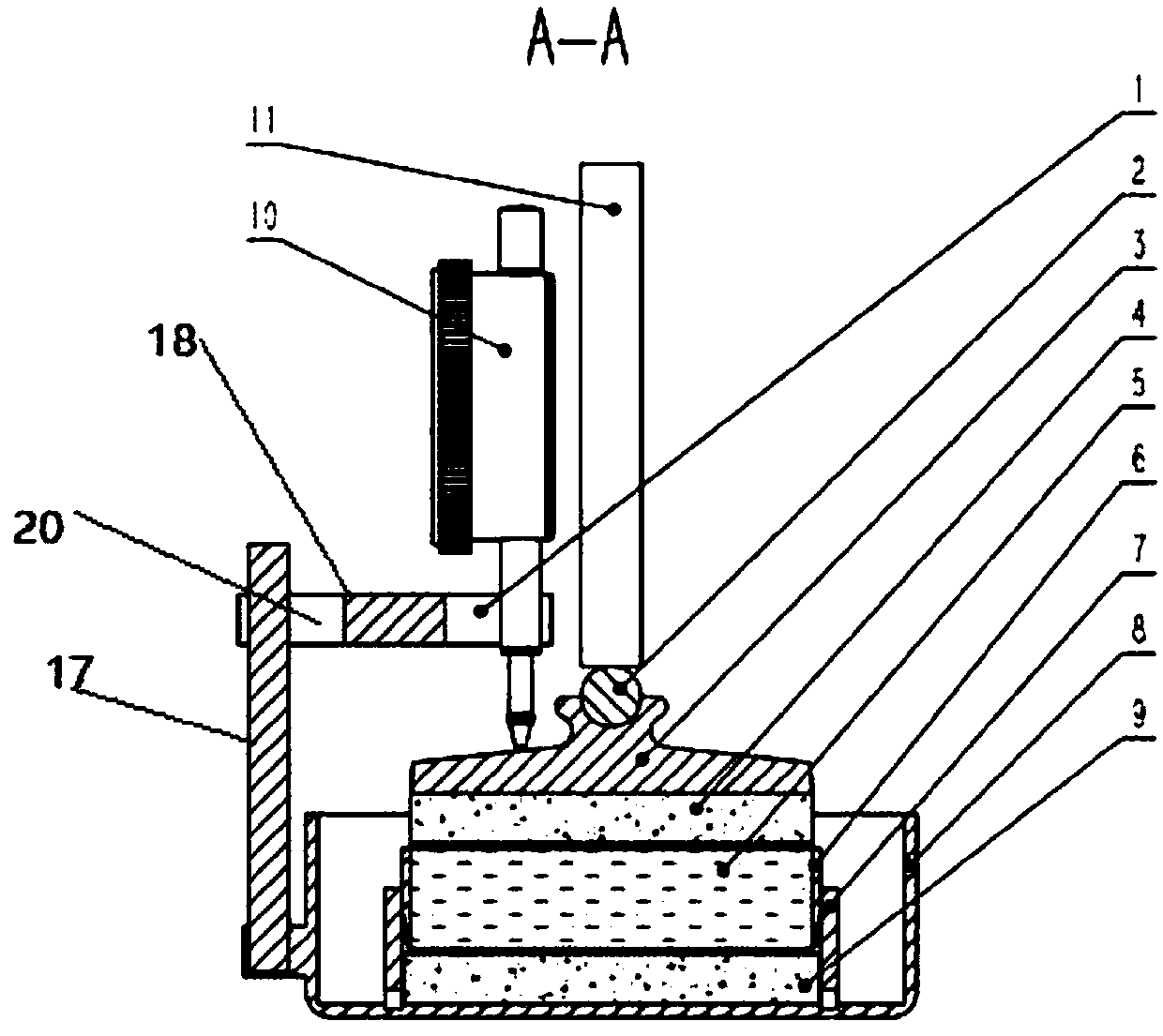

[0100] See attached figure 1 , geotextile axial compression method clogging test device, including sample container, deformation measuring device and axial pressure device 11, sample container includes water tank 8, retaining ring 7, ring knife 6, permeable plate and sample cover 3 , the retaining ring 7, the water-permeable plate and the sample cover 3 are sequentially arranged in the water tank 8, and the deformation measuring device and the axial pressure device 11 are in contact with the sample cover 3. The overall connection is convenient, easy to realize, and the structure is reasonable and convenient for measurement. ;

[0101] The water-permeable board includes a top water-permeable board 4 and a bottom water-permeable board 9, and a ring knife 6 is arranged between the top water-permeable board 4 and the bottom water-permeable board 9, and the bottom water-permeable board 4, the ring knife 6, and the top water-permeable board 9 are arranged in sequence from bottom to...

Embodiment 2

[0133] In the technical scheme of the test device of the geotextile axial compression method silting test method, the displacement sensor adopts a zero-order displacement sensor, and a linear displacement Hall sensor can be used. Placed on the surface of the sample cover 3, the sensor has high precision and high reliability, which meets the needs of the test. The displacement sensor can also be a photoelectric displacement sensor, which eliminates mechanical contact, and has a long life and high reliability.

[0134] In the technical scheme of the geotextile axial compression method clogging test method, step ⑥ and step ⑦ include a thickness measurement step in the middle, as follows

[0135] It is necessary to calculate the comprehensive permeability coefficient of the sample, the consolidation coefficient of the soil sample, the compression modulus of the soil sample and other parameters. If the change of the thickness of the geotextile with the load cannot be ignored, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com