Planar electrode structure suitable for vacuum surface flashover

A technology of surface flashover and planar electrode, which is used in the testing of dielectric strength and the construction of testing ships. It can solve problems such as energy band distortion and the impact of flashover results, and achieves reduced electric field distortion, good electric field distribution uniformity, and stable discharge. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

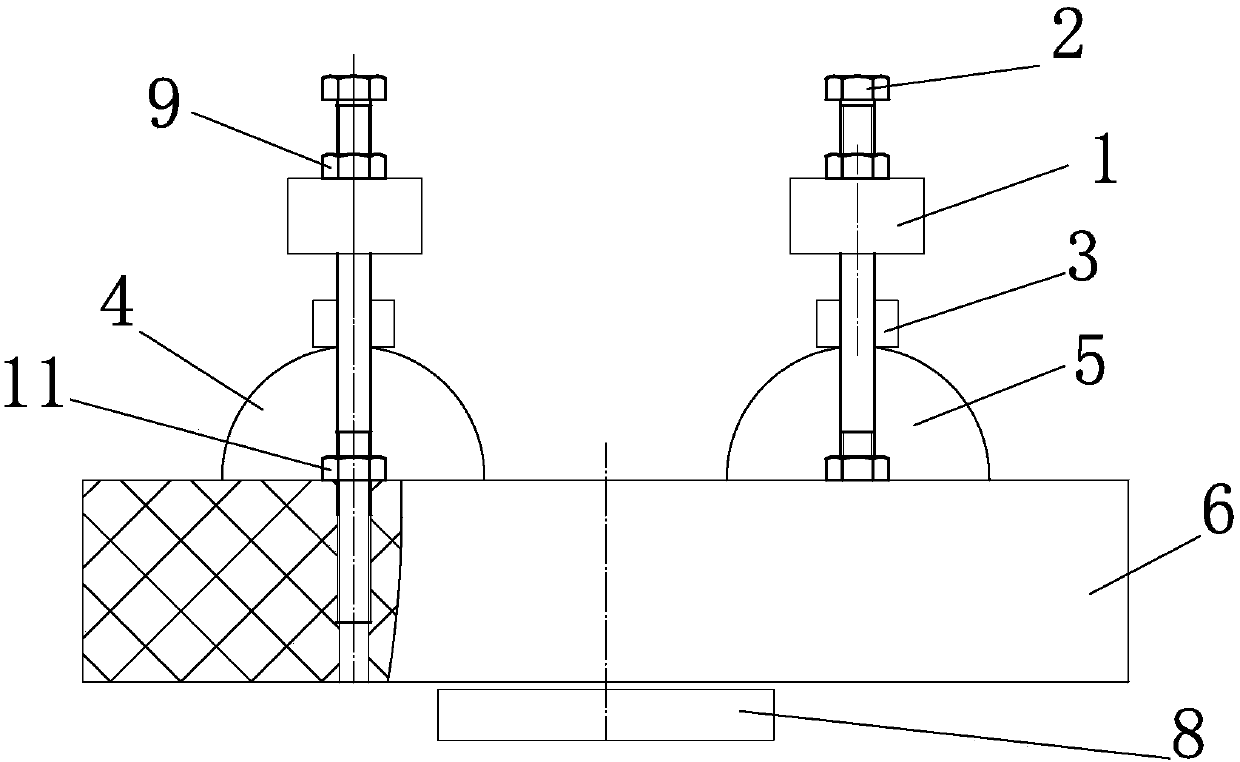

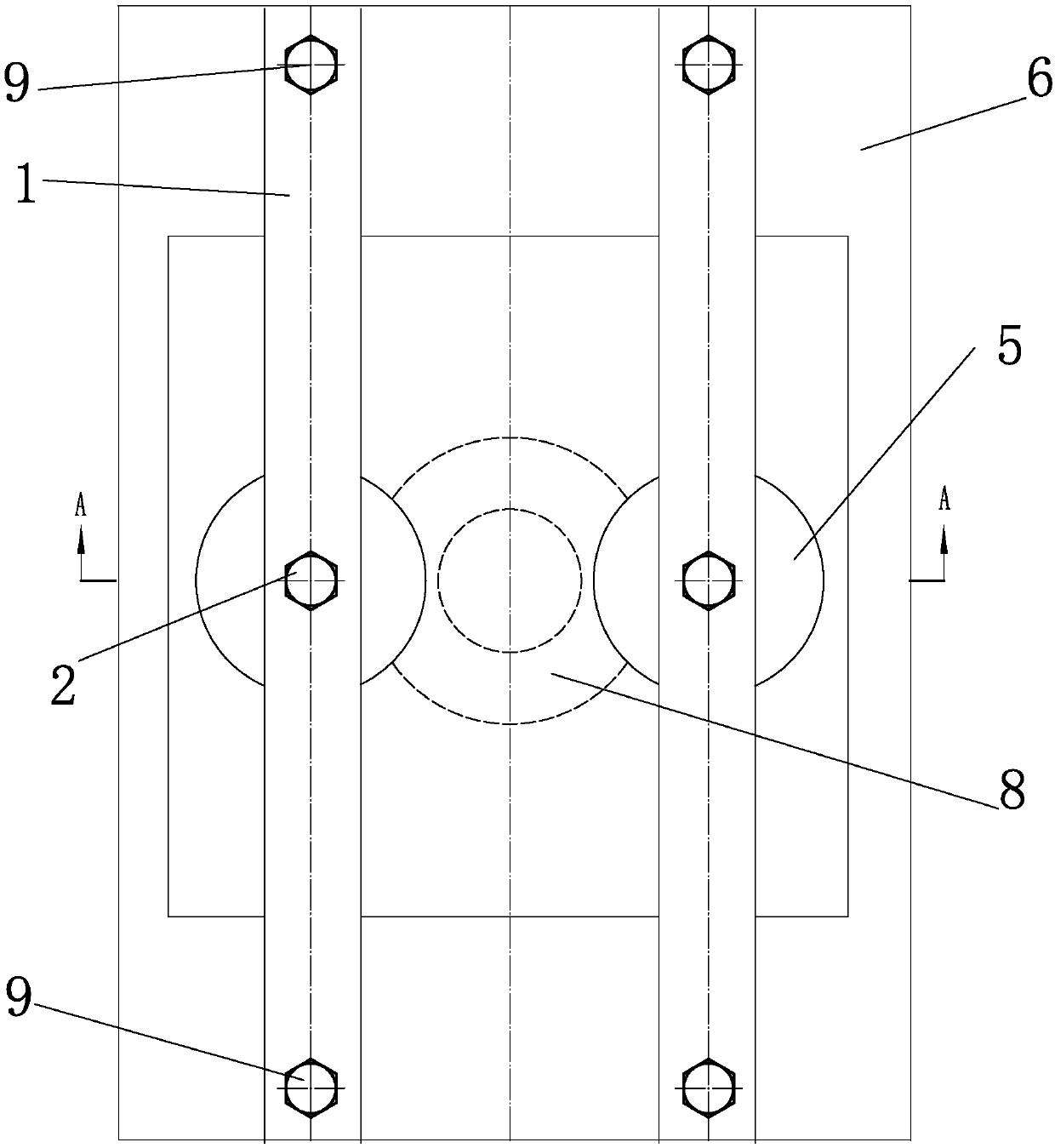

[0032] like figure 1 , image 3 , Figure 4 As shown, a planar electrode structure suitable for vacuum surface flashover includes insulating fasteners 1, high-voltage electrodes 4, ground electrodes 5, insulating supports 6, insulators 7 under test, electrode fixing bolts 2, and fixing nuts 3 , Sample fixing bolt 8, bolt two 9, groove 10, lock nut 11.

[0033] A groove 10 is provided in the middle of the upper part of the insulating support 6, and the tested insulator 7 cooperates with the groove 10. The high-voltage electrode 4 and the ground electrode 5 are in surface contact with the tested insulator 7. The high-voltage electrode 4 and the ground electrode 5 are in surface contact. The upper part is connected with the electrode pressing mechanism, and is kept in close contact with the tested insulator 7 through the pressing mechanism, and the insulating fastener is connected with the lower insulating support through the support.

[0034] The electrode pressing mechanism ...

Embodiment 2

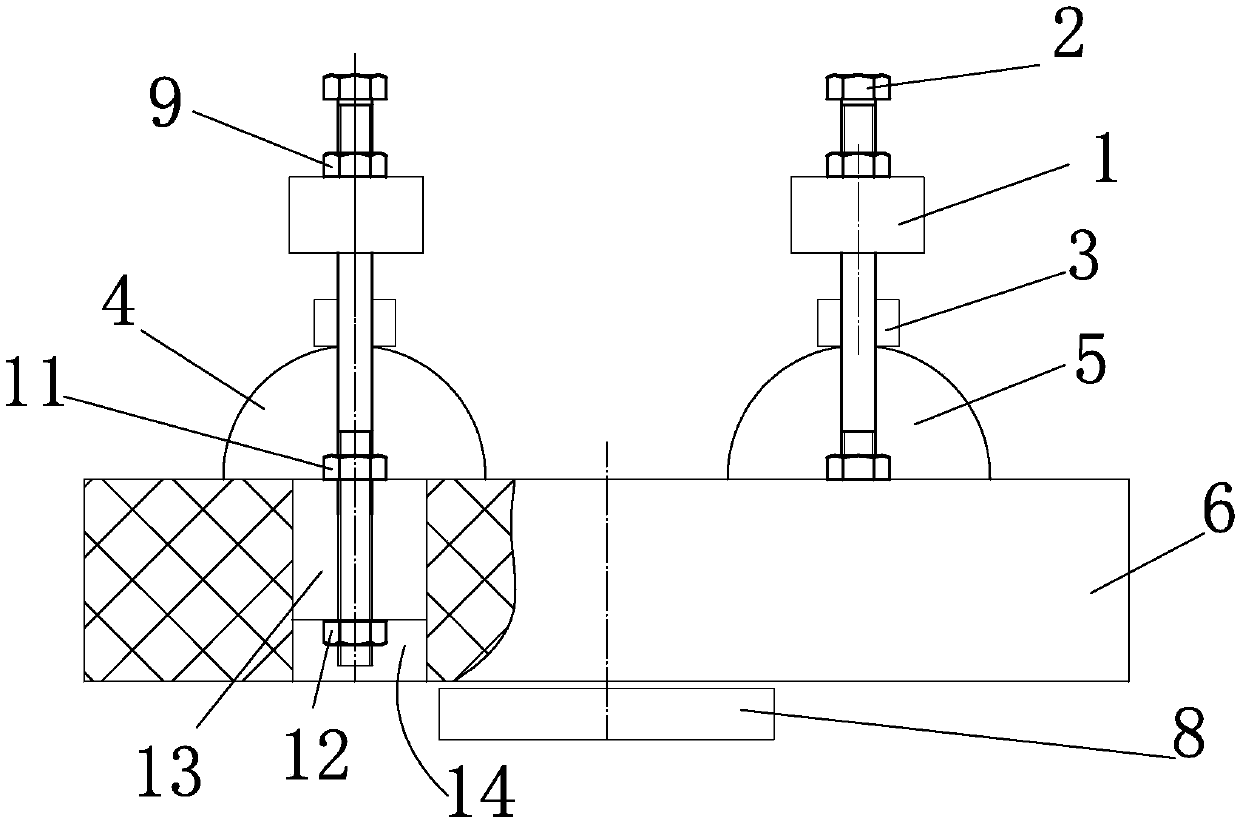

[0044] like figure 2 , Figure 5 As shown, the bottom of the insulating support 6 is provided with an opening 14, and the top of the bottom opening 14 is provided with a slotted hole 13, and a nut 2 12 is arranged in the slotted hole 13, and the nut 2 12 is threadedly matched with the lower end of the bolt 2 9. Since the slotted hole 13 is provided on the upper part of the bottom opening, the second nut 12 and the second bolt 9 can move left and right in the slotted hole 13, and the distance between the high voltage electrode 4 and the ground electrode 5 can be adjusted at will, and the adjustment range of the discharge gap is wide. It is conducive to scientific research and engineering simulation, has a wider range of use, and has better practical application value and promotion value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com