The connection assembly connecting the liquid storage tank and the liquid outlet pipe in the liquid sales equipment

A technique for connecting assemblies, reservoirs, coin-operated devices for dispensing discrete items, coin-operated devices for controlling the dispensing of fluids/particulate materials from containers, coin-free or similar appliances, etc., capable of Solve the problems of complex structure, high cost, falling slag, etc., to achieve the effect of reliable connection, quick installation and separation, and firm locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

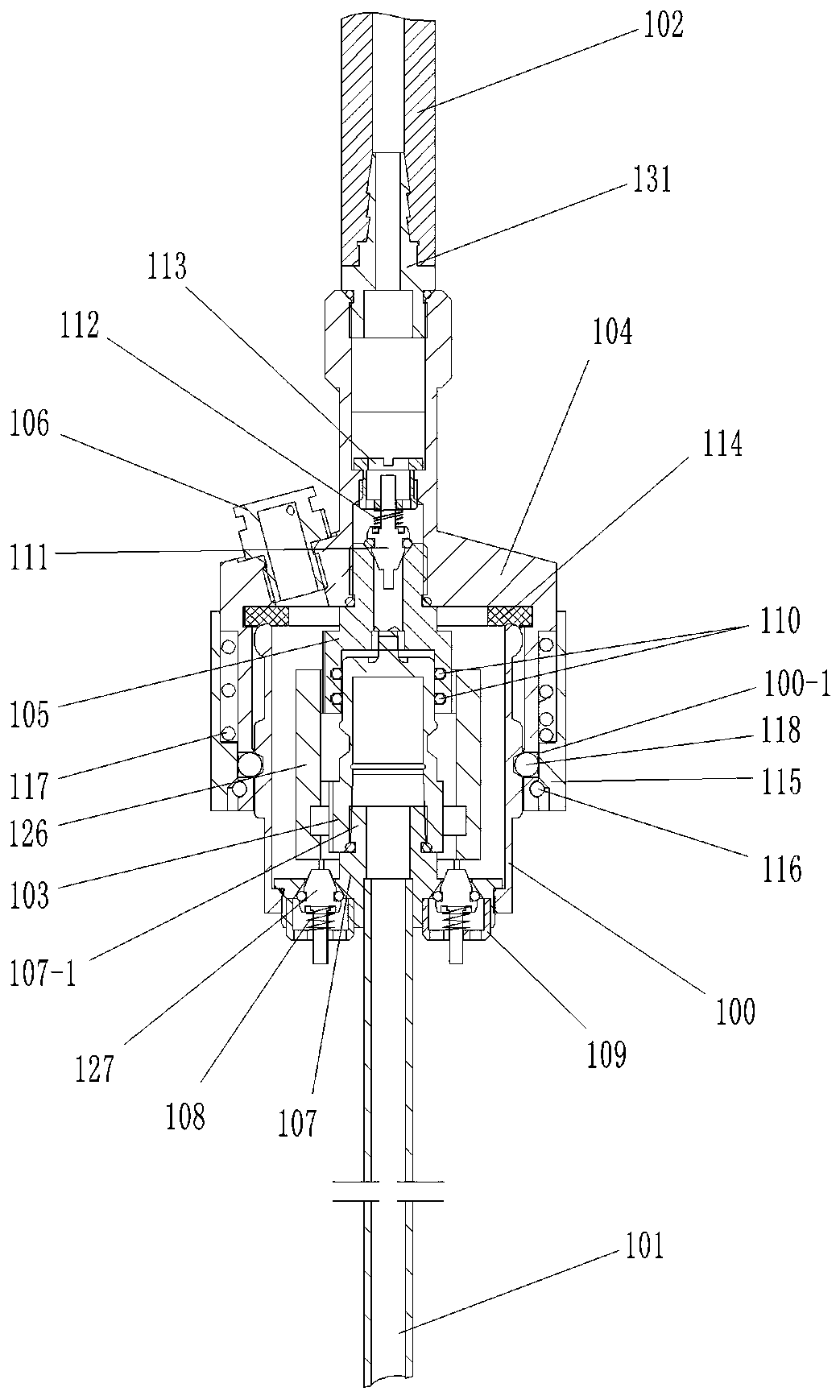

[0015] Embodiment one, see appendix figure 1 , the present invention provides a connection assembly for connecting a liquid storage barrel and a liquid outlet pipe in a liquid selling device, which is used to connect the liquid suction pipe 101 located inside the liquid storage barrel and the liquid outlet pipe 102 located outside the liquid storage barrel, including The liquid outlet connector 103 connected to the liquid suction pipe 101 and having a one-way valve structure provided in the mouth of the liquid storage barrel 100, the intermediate connecting sleeve 104 connected to the mouth of the liquid storage barrel 100 and the liquid outlet pipe 102 respectively, The key is: when the intermediate connecting sleeve 104 is connected to the mouth of the liquid storage barrel 100, a one-way air inlet channel and a normally closed one-way air inlet channel are provided in the closed space formed between the intermediate connecting sleeve 104 and the mouth of the liquid storage b...

Embodiment 2

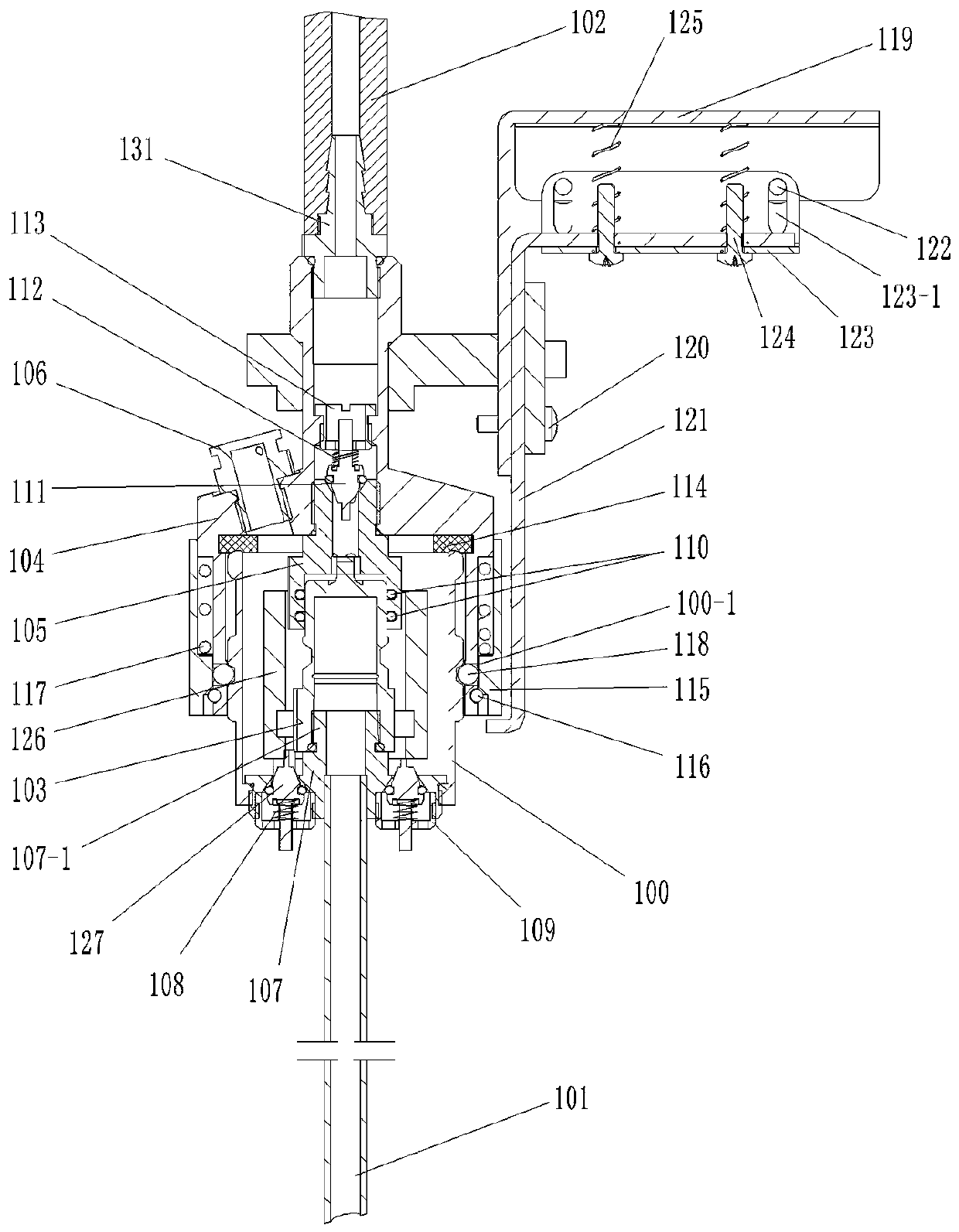

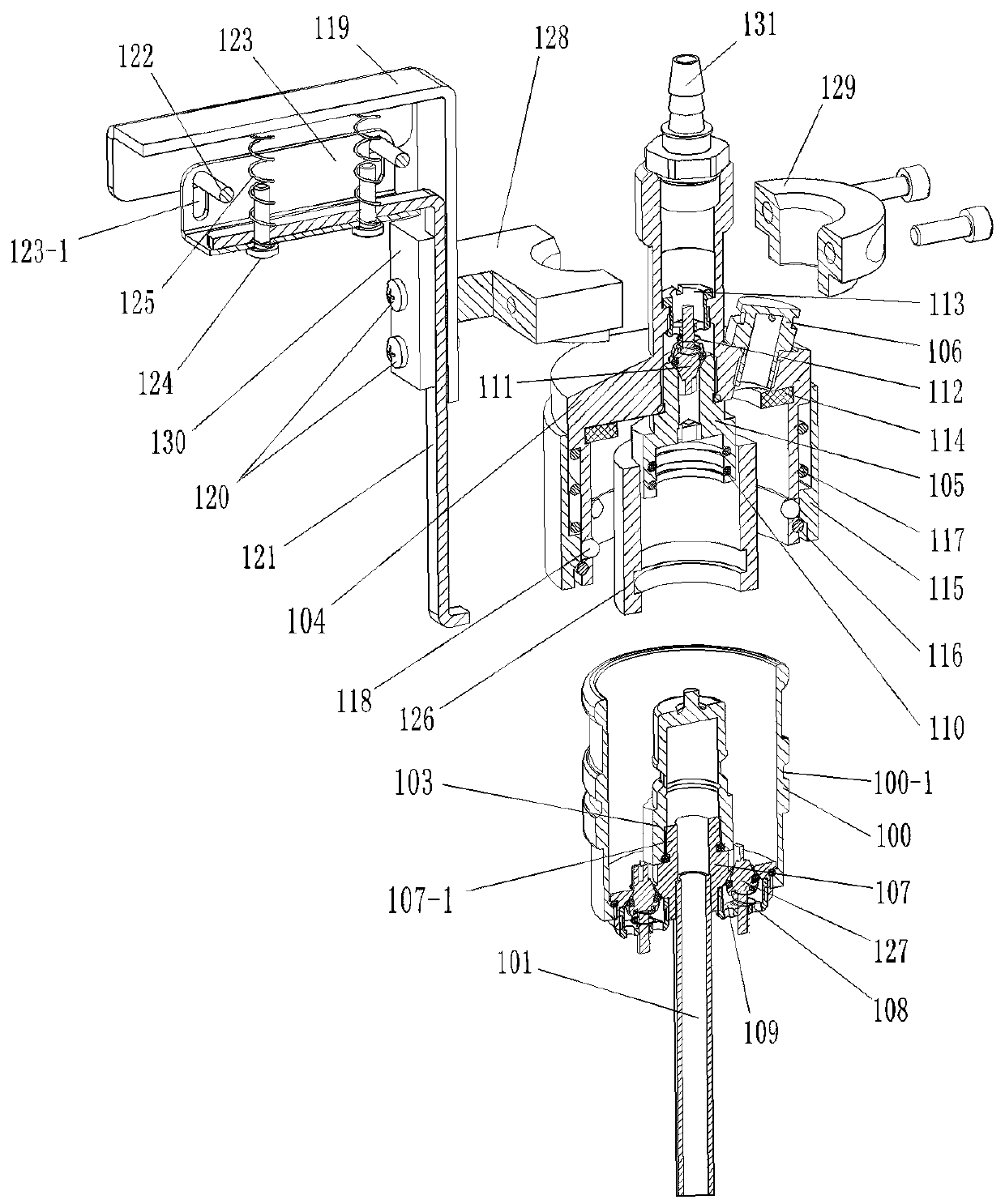

[0030] Embodiment two: see attached figure 2 with 3 , the difference from the first embodiment is that, in order to facilitate the connection and separation of the intermediate connecting sleeve 104 and the barrel mouth 100 of the liquid storage barrel, the intermediate connecting sleeve 104 is provided with a quick disassembly structure matched with the quick assembly structure.

[0031] The above-mentioned quick disassembly structure includes a handle 119 fixed on the intermediate connecting sleeve 104 by means of a mounting assembly and a shift fork 121 limited on the handle 119 by means of a limit screw 120, and a slide groove is provided on the shift fork 121 described above. The above-mentioned limit screw 120 is connected to the handle 119 through the chute, the bottom of the above-mentioned shift fork 121 is bent toward the side of the ferrule 115 and the bent part is located below the ferrule 115, and the top of the above-mentioned shift fork 121 faces toward the han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com