Milling device for case fans

A milling device and fan technology, applied in positioning devices, clamping devices, milling machines, etc., can solve problems such as difficult operation, wear of chassis fans, and affecting normal rotation of fan blades, so as to achieve accurate milling process, improve work efficiency, and realize automation Transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

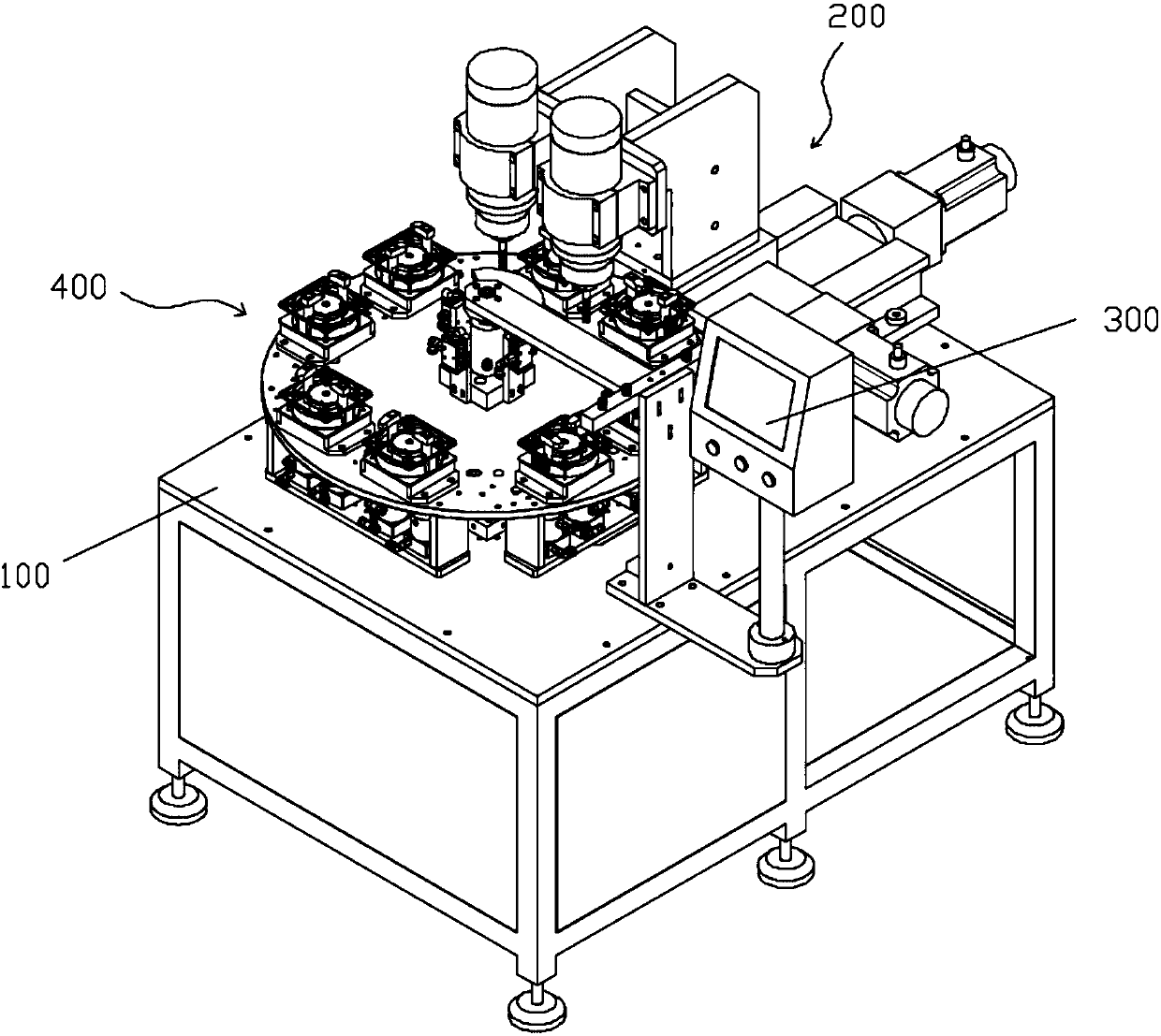

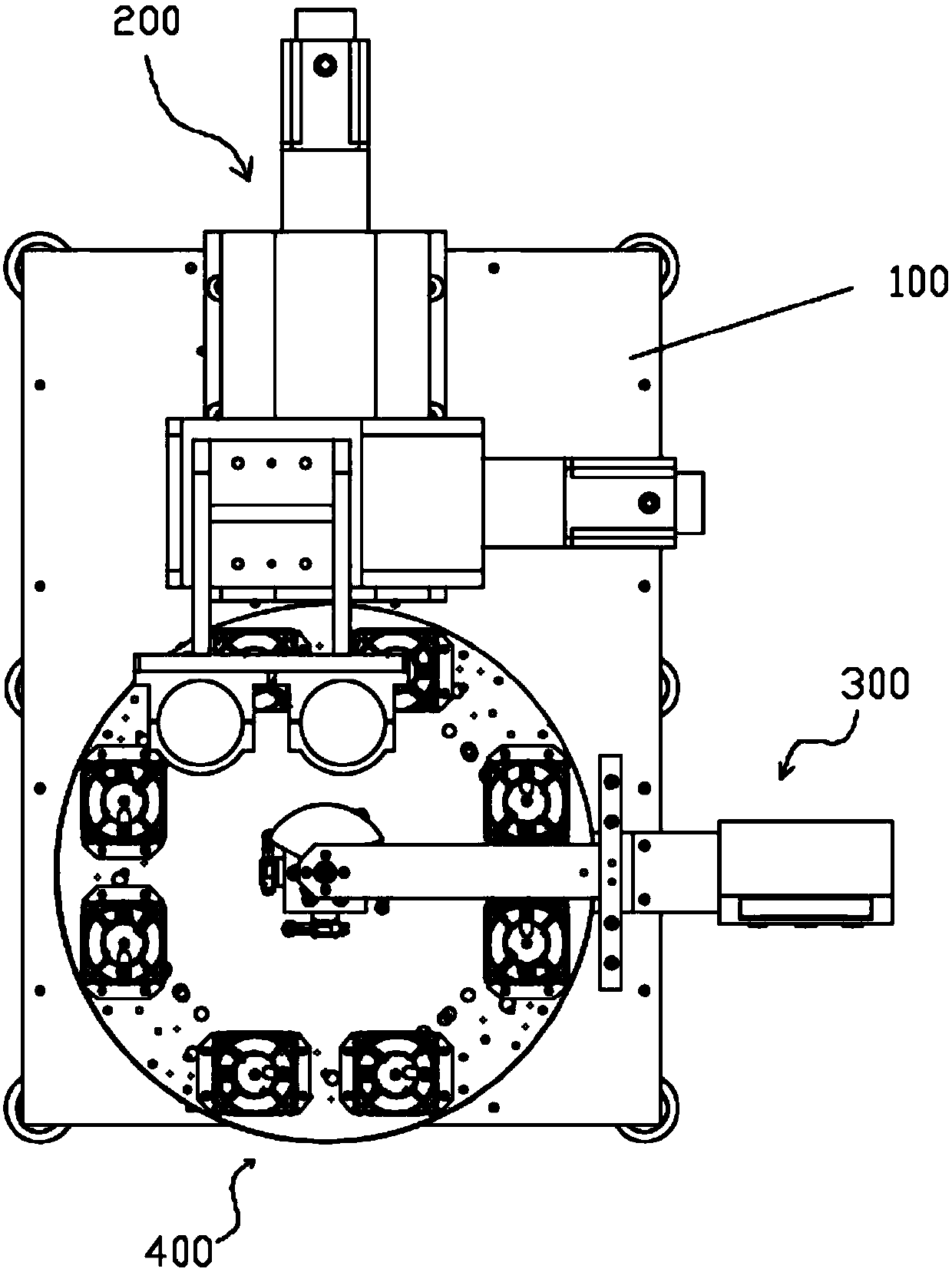

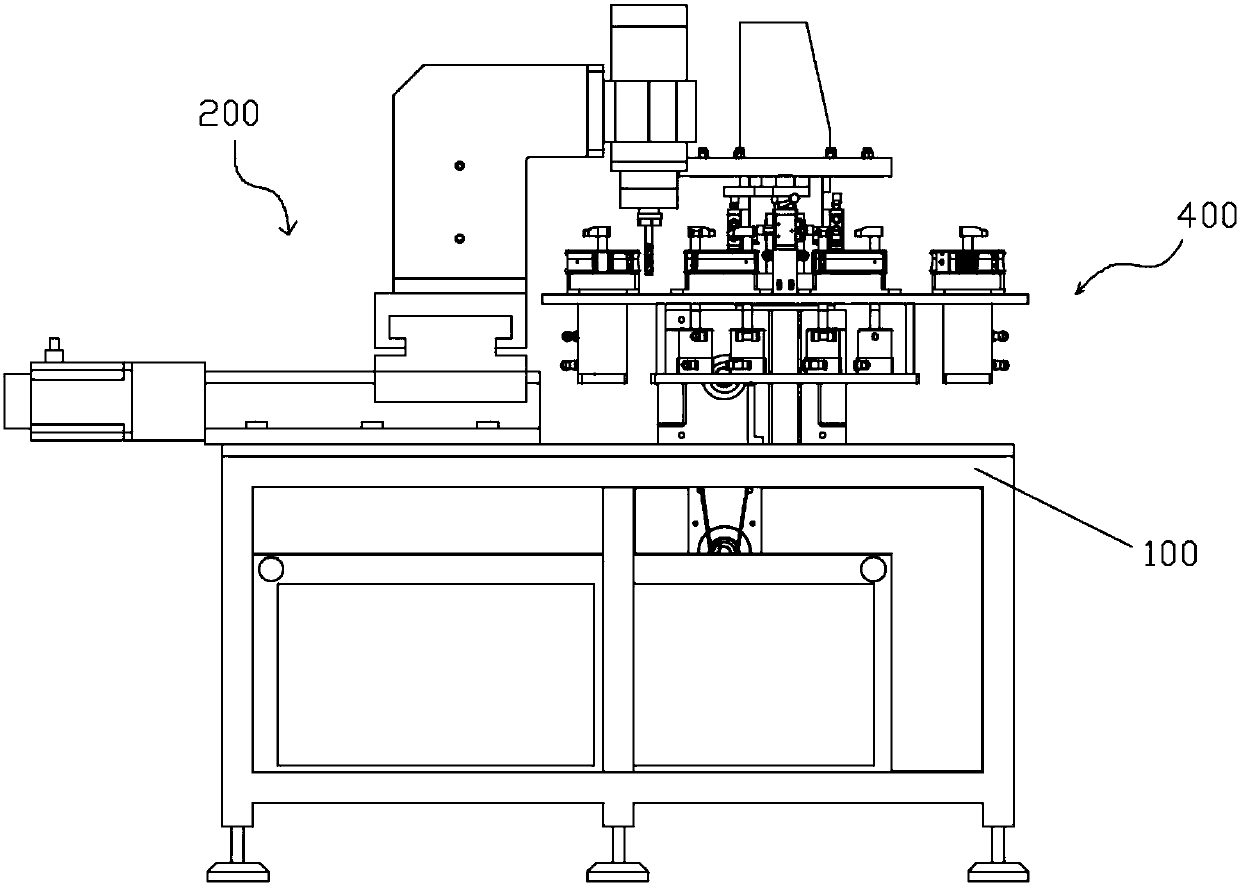

[0030] Such as Figure 1-4 As shown, a milling device for a chassis fan includes a base 100, which is placed horizontally on the ground; the base 100 is provided with a milling mechanism 200, a transmission mechanism 400 and a control mechanism 300, and the milling mechanism 200 is used to drive the milling cutter 233 Move so that the milling cutter 233 can move in all directions on the milling mechanism 200, the transmission mechanism 400 is connected with the base 100 in rotation, the transmission mechanism 400 is used to load the chassis fan, and the transmission mechanism 400 is provided with eight chassis fans, eight chassis fans The fans are located in four different directions. Two chassis fans form a group and are arranged in pairs. The transmission mechanism 400 is used to drive the position of the chassis fans, so that the chassis fans cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com