Integral annular conveying belt

An endless conveyor belt and conveyor belt technology, applied in the field of conveyor belts, can solve the problems of increased space occupation of the drive motor, asynchronous operation of the conveyor belt, and affecting the transfer effect of workpieces, etc., to save space, prevent asynchronous operation, and excellent Effects of insulation and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

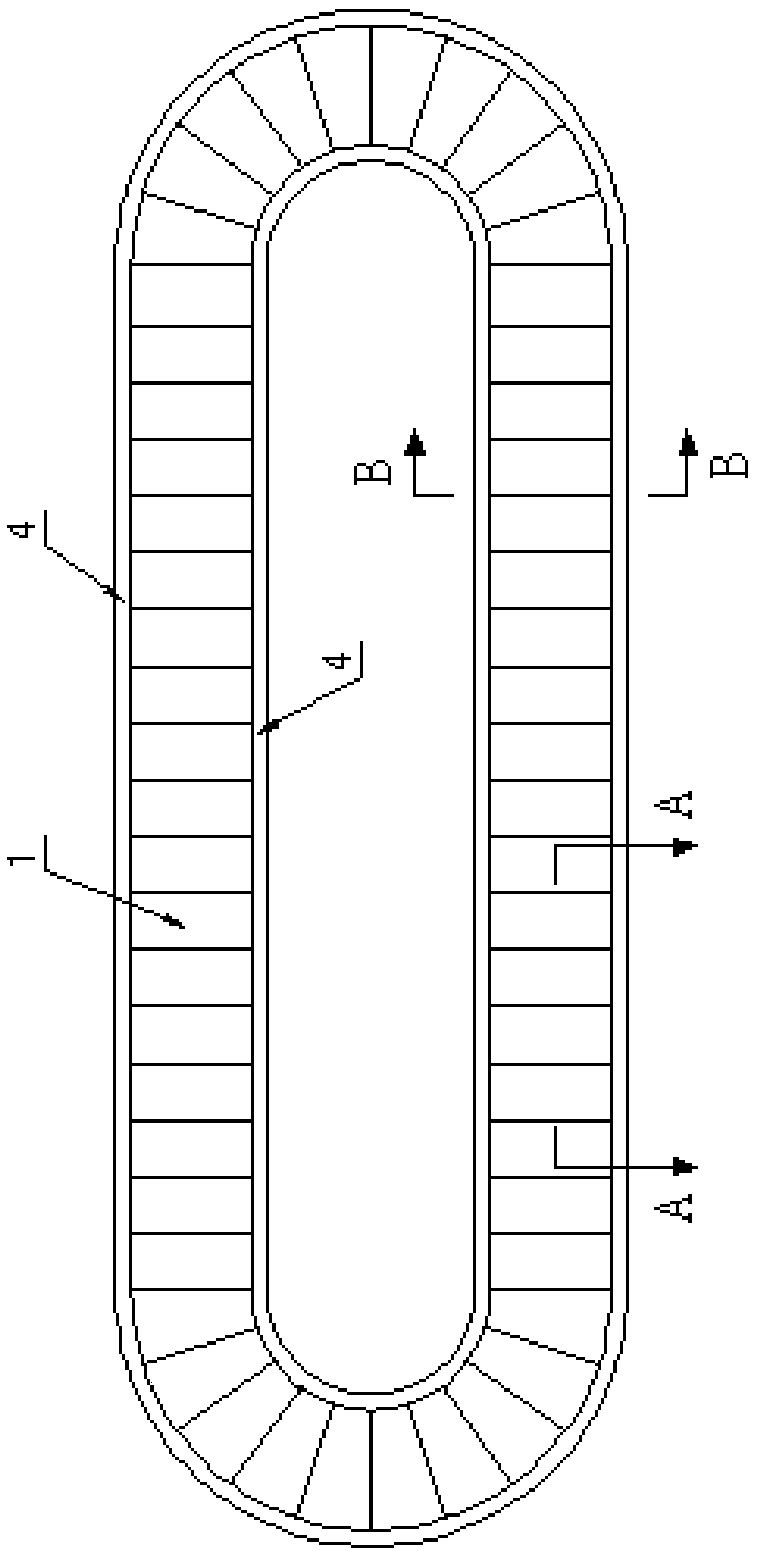

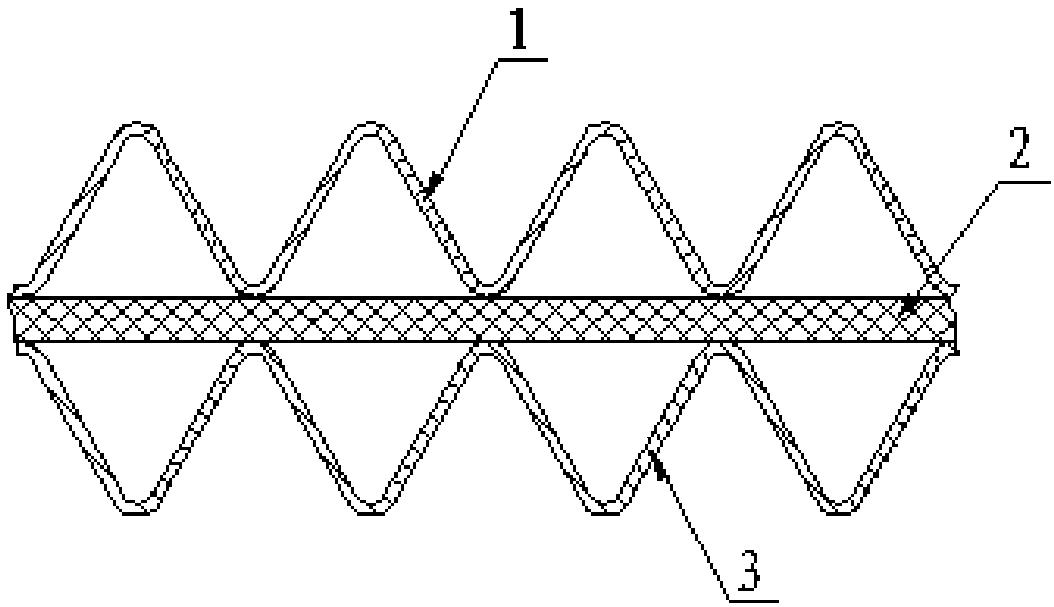

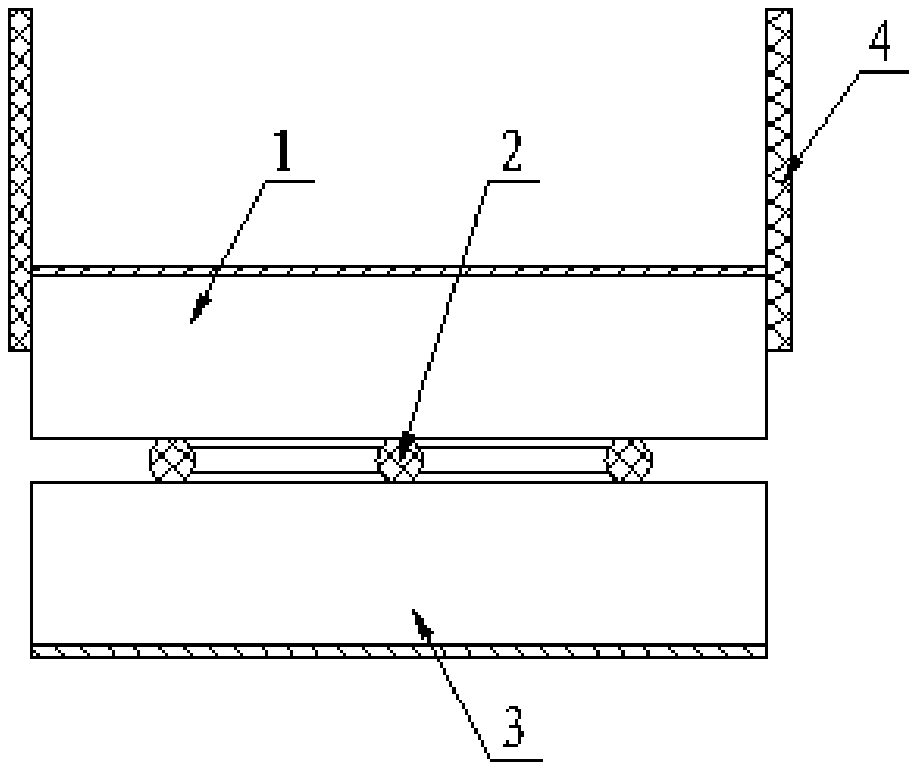

[0020] Embodiment 1: a kind of integral endless conveyer belt, as Figure 1 ~ Figure 3 As shown, including the upper base layer 1 of the conveyor belt, the skeleton of the conveyor belt 2, the lower base layer 3 of the conveyor belt and the soft baffle 4, the upper base layer 1 of the conveyor belt and the lower base layer 3 of the conveyor belt are folded organ-shaped bodies to form a ring-shaped overall conveyor belt The upper base layer 1 of the conveyor belt and the lower base layer 3 of the conveyor belt are formed by needle punching of an aramid fiber layer and an industrial filament cloth layer, the industrial filament cloth layer is a nylon filament cloth layer, and the aramid fiber layer is wool Mesh short fiber layer, three conveyor belt skeletons 2 are equidistantly arranged between the conveyor belt upper base 1 and the conveyor belt lower base 3, and the conveyor belt skeleton 2 is along the direction of enclosing the conveyor belt upper base 1 and the conveyor low...

Embodiment 2

[0021] Embodiment 2: The difference from Embodiment 1 is that the upper base layer 1 of the conveyor belt and the lower base layer 3 of the conveyor belt are formed by needle punching of aramid fibers and non-alkali glass fiber cloth layers.

Embodiment 3

[0022] Embodiment 3: The difference from Embodiment 1 or 2 is that the outer covering layer is a rubber covering layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com