A kind of functional sublimation transfer printing paper and its preparation method and application

A transfer printing paper, a functional technology, applied in the temperature recording method, etc., can solve the problems of not being able to impart functionality to the transfer object, single load transfer force, and affecting printing performance, etc., to achieve the best transfer effect and functionality, and easy to control , easy to implement and amplify the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

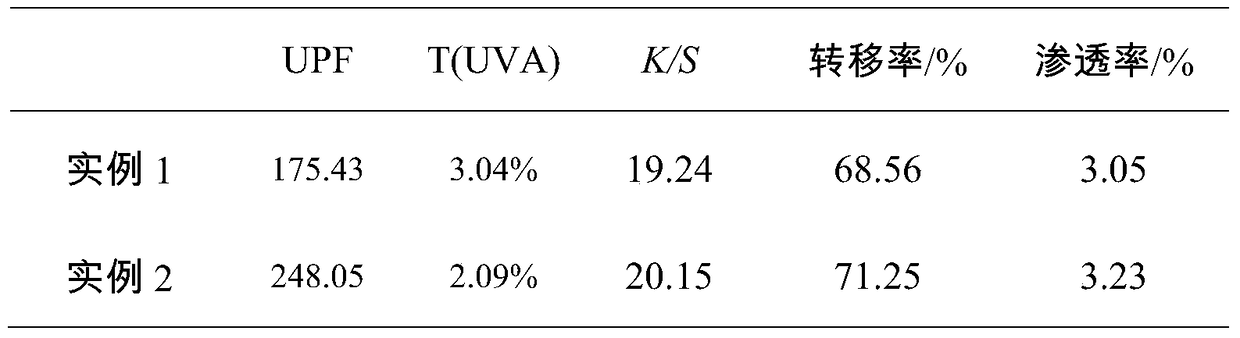

Embodiment 1

[0027] A functional sublimation transfer printing paper, including paper and a coating on the surface of the paper, the coating is a transfer substrate, including a polymer thickener and an inorganic nano material, and the rest is a solvent.

[0028] Wherein the inorganic nano material is a kind of inorganic nano particle or a mixture of several inorganic nano particles. It is especially preferred that the inorganic nanomaterials include one or more of nano-silicon dioxide, nano-titanium dioxide, and nano-zinc oxide. The solvent is water, or an organic solvent, or a mixed solution of water and an organic solvent. Meanwhile, the organic solvent is ethanol, isopropanol, or a mixture of the two.

[0029] Specifically in this embodiment, the transfer substrate includes a polymer thickener with a content of 15% (w / w) and an inorganic nanomaterial with a content of 0.25% (w / w), and the rest is a solvent. The inorganic nano material is nano silicon dioxide, the polymer thickener is...

Embodiment 2

[0058]A functional sublimation transfer printing paper, the difference from Example 1 is: the formula of the transfer substrate includes a polymer thickener with a content of 10% (w / w) and a content of 0.75-1.75% (w / w) ) of inorganic nanomaterials, and the rest are solvents.

[0059] Wherein the inorganic nano material is specifically a mixture of 0.25% (w / w) nano-silicon dioxide and 0.5-1.5% (w / w) nano-titanium dioxide which account for the transfer substrate. The polymer thickener is also low-viscosity sodium carboxymethyl cellulose, and the solvent is a mixture of water and ethanol in any ratio.

[0060] The difference between the preparation method of the above-mentioned functional sublimation transfer printing paper and the corresponding method in Example 1 is:

[0061] The formula for configuring the transfer substrate in step (1) adopts the specific formula of Example 2.

[0062] The coating thickness in step (2) is 0.2 mm.

[0063] In step (3), the baking temperatur...

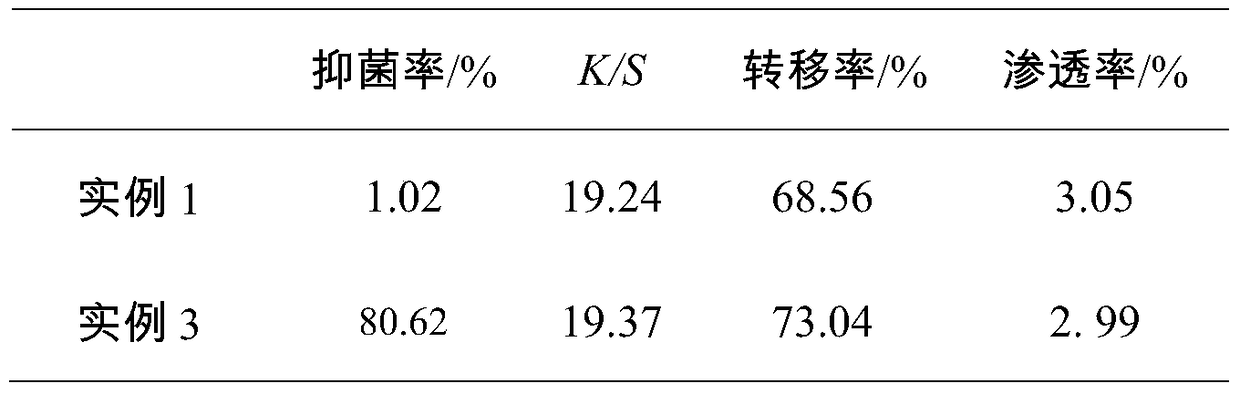

Embodiment 3

[0072] A functional sublimation transfer printing paper, the difference from Example 1 is: the formula of the transfer substrate includes a polymer thickener with a content of 5% (w / w) and a content of 1.0-2.5% (w / w) ) of inorganic nanomaterials, and the rest are solvents.

[0073] The inorganic nano material is specifically a mixture of 0.5% (w / w) nano silicon dioxide and 0.5-2% (w / w) nano zinc oxide which account for the transfer substrate. The polymer thickener is also low-viscosity sodium carboxymethyl cellulose, and the solvent is water.

[0074] The difference between the preparation method of the above-mentioned functional sublimation transfer printing paper and the corresponding method in Example 1 is:

[0075] The formula for configuring the transfer substrate in step (1) adopts the unique formula of Example 3. The configuration is to stir for 1 hour at a rotating speed of 500 rpm, thereby making a milky white viscous transfer substrate.

[0076] The coating thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com