A kind of copolymer and its preparation method and use

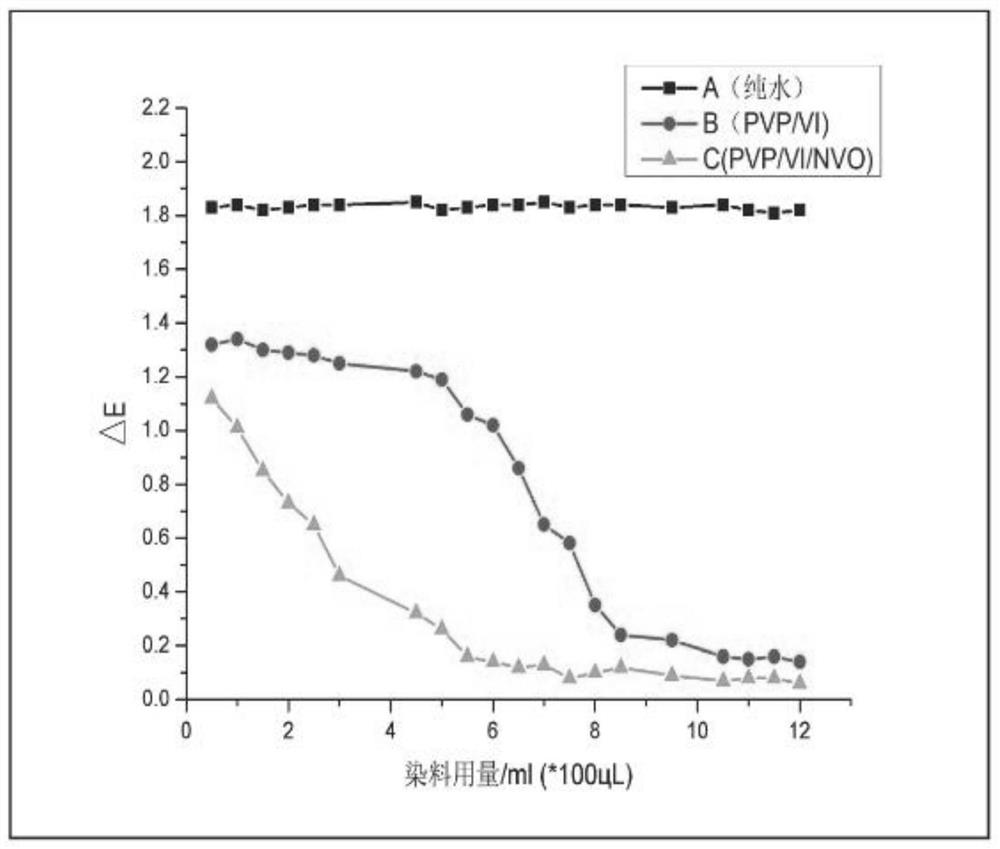

A technology of copolymers and polymers, which is applied in the direction of chemical instruments and methods, dyeing methods, detergent compositions, etc., can solve the problems of weakening dye complexation or adsorption capacity, resistance to dye migration agent, etc., to ensure dispersibility And anti-dye transfer performance, strong complexation and adsorption capacity, good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

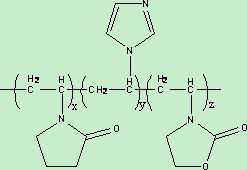

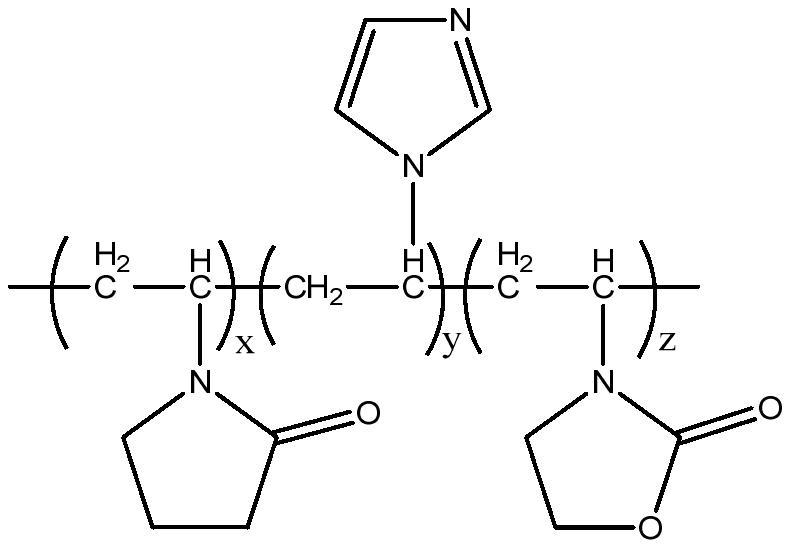

Embodiment 1

[0037]Nitrogen was replaced in a four-necked flask equipped with mechanical stirring, constant pressure dropping, and a funnel thermometer, then 200 g of purified water was added, the pH was adjusted to 7-9 with ammonia water, stirring was started, and when the temperature was raised to 45 ° C, vinylpyrrolidone ( NVP) 14.9884g (0.1349mol), vinylimidazole (VI) 45.00g (0.4782mol), vinyl oxazolidinone (NVO) 10.00g (0.0885mol), when the temperature rises to 68°C, add AIBN 0.5g, and carry out Pre-polymerize for about 50 minutes; continue to heat up to 72°C, add 2g of AIBN, and drop the remaining vinylpyrrolidone 30.0116g (0.2694mol) at the same time, dropwise for about 1.5h, then keep warm for 3h, heat up to 75°C, add azo 0.3g of diisobutylamine hydrochloride was carried out three times to eliminate residues, once every 1h, and finally obtained a copolymer with a concentration of about 30wt%, the solution was faintly light yellow, and the content NVP of each residue in the solution ...

Embodiment 2

[0039] Nitrogen was replaced in a four-necked flask equipped with mechanical stirring, constant pressure dropping, and a funnel thermometer, then 200 g of purified water was added, the pH was adjusted to 7-9 with ammonia water, stirring was started, and when the temperature was raised to 45 ° C, vinylpyrrolidone ( NVP) 14.9884g (0.1349mol), vinylimidazole (VI) 45.00g (0.4782mol), vinyl oxazolidinone (NVO) 10.00g (0.0885mol), when the temperature rises to 68°C, add AIBN 0.5g, and carry out Pre-polymerize for about 50 minutes; continue to heat up to 72°C, add AIBN 3g, and drop the remaining vinylpyrrolidone 30.0116g (0.2694mol) at the same time, dropwise for about 1.5h, then keep warm for 3h, heat up to 75°C, add azo Diisobutylamine hydrochloride 0.3g, carried out three times to eliminate residues, once every 1h, and finally obtained a copolymer with a concentration of about 30wt%, the solution was faintly light yellow, and the NVP content of each residue in the solution was 9.46...

Embodiment 3

[0041] Nitrogen was replaced in a four-necked flask equipped with mechanical stirring, constant pressure dropping, and a funnel thermometer, then 200 g of purified water was added, the pH was adjusted to 7-9 with ammonia water, stirring was started, and when the temperature was raised to 45 ° C, vinylpyrrolidone ( NVP) 14.9884g (0.1349mol), vinylimidazole (VI) 45.00g (0.4782mol), vinyl oxazolidinone (NVO) 10.00g (0.0885mol), when the temperature was raised to 68°C, V50 0.5g was added to carry out Pre-polymerize for about 50 minutes; continue to heat up to 72°C, add V50 3g, and drop the remaining vinylpyrrolidone 30.0116g (0.2694mol) at the same time, dropwise for about 1.5h, then keep warm for 3h, heat up to 75°C, add azo Diisobutylamine hydrochloride 0.3g, carried out three times to eliminate residues, once every 1h, and finally obtained a copolymer with a concentration of about 30wt%, the solution was faintly light yellow, and the NVP of each residue in the solution was 8.51 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com