Fermentation device

A technology of fermentation equipment and fermentation tank, which is applied in the field of brewing, can solve the problems of low automation, high cleaning intensity, and high labor intensity, and achieve the effects of high automation, reduced cleaning work, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

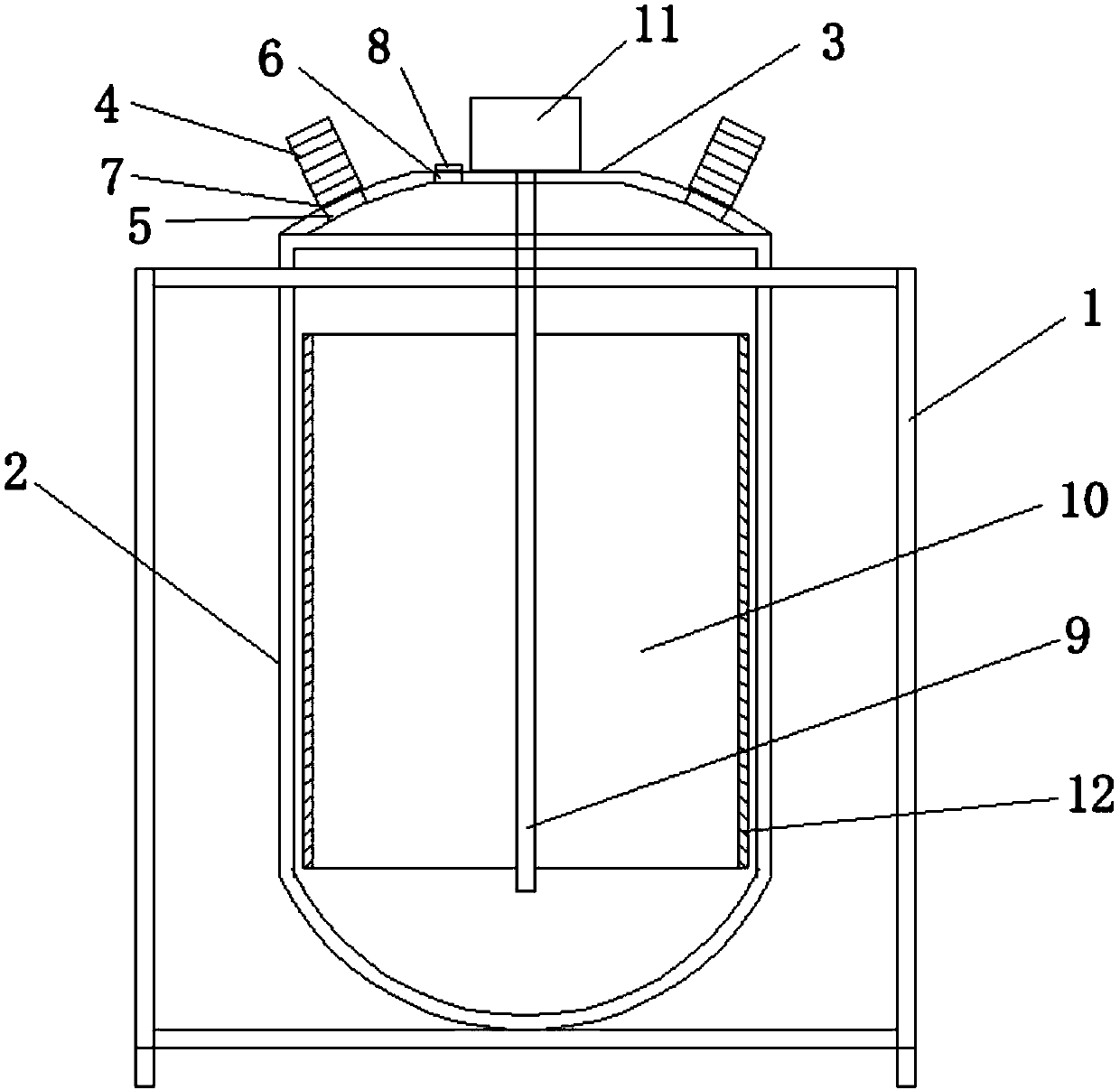

[0023] This embodiment provides a fermentation equipment, including a frame 1, a fermenter and a detection device 4, the fermenter is installed on the frame 1, and the detection device 4 is arranged on the fermenter.

[0024] The fermenter comprises a tank body 2 and a tank cover 3, the tank body 2 has an opening, the tank cover 3 is detachably arranged on the tank body 2 and can close the opening, the tank body 2 and the The tank cover 3 cooperates to form a sealed fermentation chamber inside the fermenter. The tank cover 3 is provided with an observation hole 5 and an air vent 6. The observation hole 5 is covered with a transparent elastic film 7. The elastic The membrane 7 is in sealing connection with the observation hole 5, and the vent hole 6 is equipped with a one-way valve 8 for discharging the gas in the fermentation chamber. The one-way valve can discharge the gas in the fermentation chamber.

[0025] The detection device 4 includes a housing, a detection film, a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com