Modifier specially used for casting aluminum alloy for IC equipment and modifying treatment method

A technology for casting aluminum alloy and modification treatment, which is applied in the field of modification agent, which can solve the problems of inconvenient multiple modification treatment, long residence time of molten aluminum, deterioration and recession of castings, etc., to achieve long duration of modification, reduce the number of repeated modification treatments, delay The effect of metamorphic decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

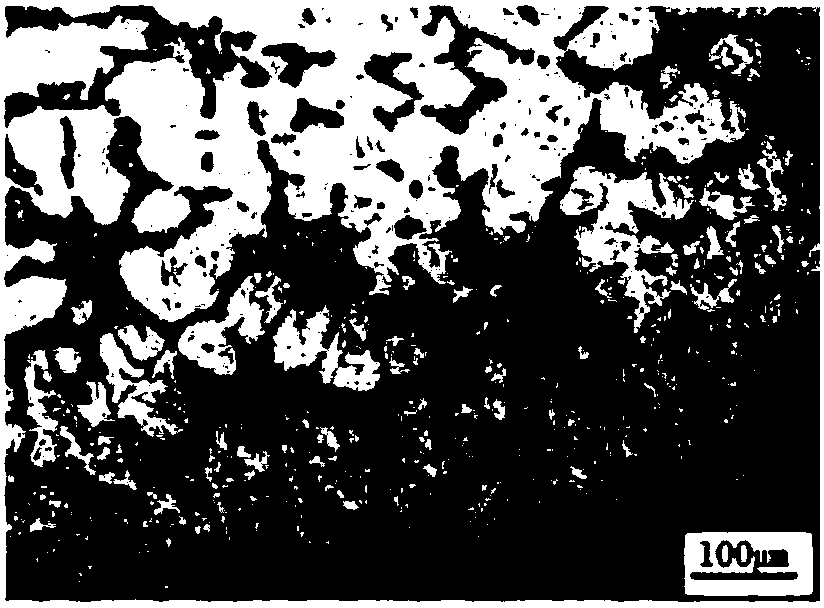

Image

Examples

Embodiment 1

[0039] Embodiment 1: the preparation of modifier

Embodiment 1-1

[0041] The preparation of modifier A: the raw materials used are in weight percent, 63.6% aluminum cerium alloy powder (wherein Ce content is 55%, surplus is Al), 12% aluminum strontium alloy powder (wherein Sr content is 25%, surplus Al), 4.5% electrolytic manganese powder (purity 99.9%), 10% metal Bi powder (purity 99.9%) and 9.9% metal Al powder (A00) are mixed evenly, and pressed into a cylinder of Φ10×10mm on a briquetting machine shaped particles to obtain modificator A;

[0042] The preparation of modificator B: the raw materials used are in percent by weight, the NaCl of 22%, the KCl of 22%, the NaF of 45%, 6%SrCO 3 , 3%K 2 TiF 6 and 2% BaCl 2 Mix evenly, and press on a briquetting machine to form cylindrical particles of Φ10×10mm to obtain Modifier B.

Embodiment 1-2

[0044] The preparation of modifier A: the raw materials used are in weight percent, 72.7% aluminum cerium alloy powder (wherein Ce content is 55%, surplus is Al), 10% aluminum strontium alloy powder (wherein Sr content is 25%, surplus Al), 5% electrolytic manganese powder (purity 99.9%), 8% metal Bi powder and 4.3% metal Al powder (A00) (purity 99.9%) are mixed evenly, and pressed into a cylinder of Φ10×10mm on a briquetting machine shaped particles to obtain modificator A;

[0045] The preparation of modificator B: the raw materials used are in percent by weight, the NaCl of 20%, the KCl of 23%, the NaF of 46.5%, 5%SrCO 3 , 4%K 2 TiF 6 and 1.5% BaCl 2 Mix evenly, and press on a briquetting machine to form cylindrical particles of Φ10×10mm to obtain Modifier B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com