Central powder conveying-type expandable multi-beam laser cladding head and application thereof

A technology of laser cladding and powder feeding, which is applied in the coating process and coating of metal materials, etc., can solve the problems of difficult processing of reflective diffusers and reflective focusing components, inability to use laser cladding, and the influence of self-reflectivity, etc. Achieve the effect of avoiding equipment downtime and unable to use normally, reducing the risk of equipment failure, and being easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

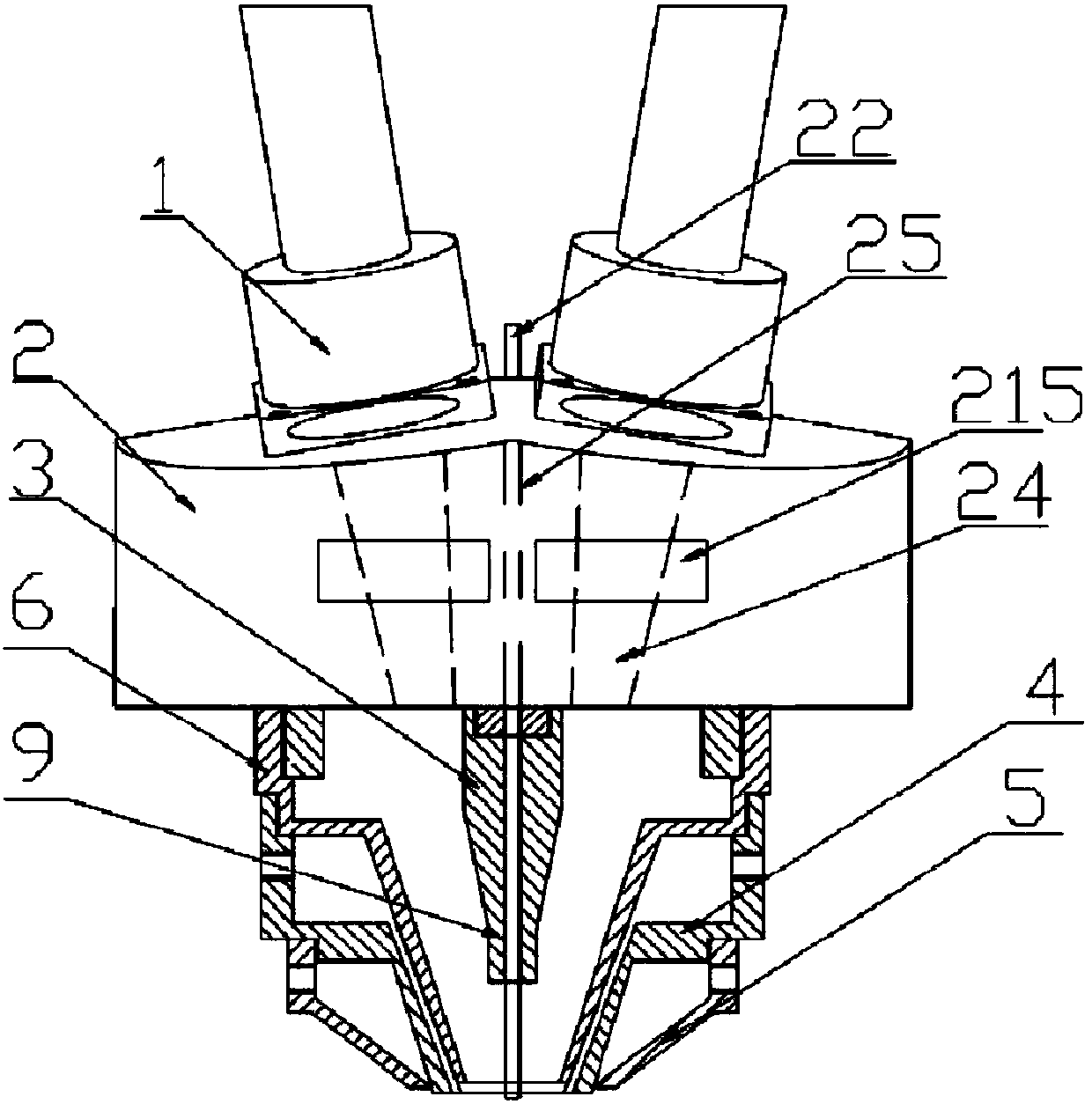

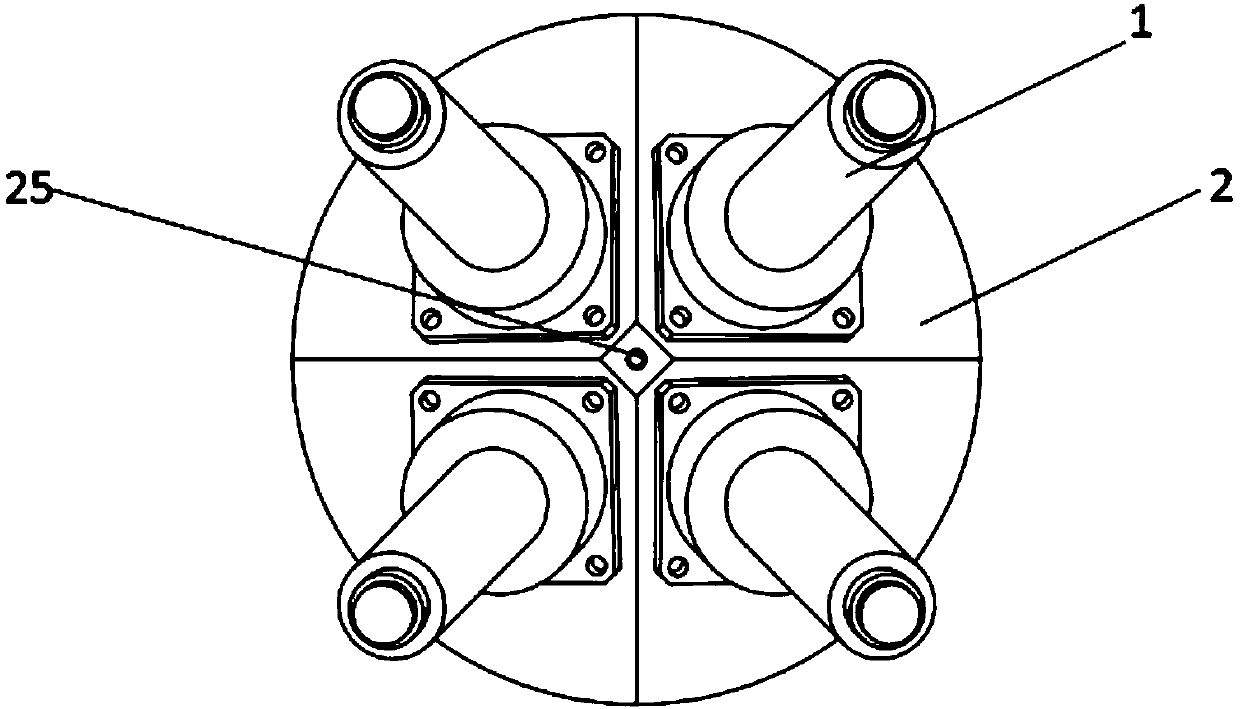

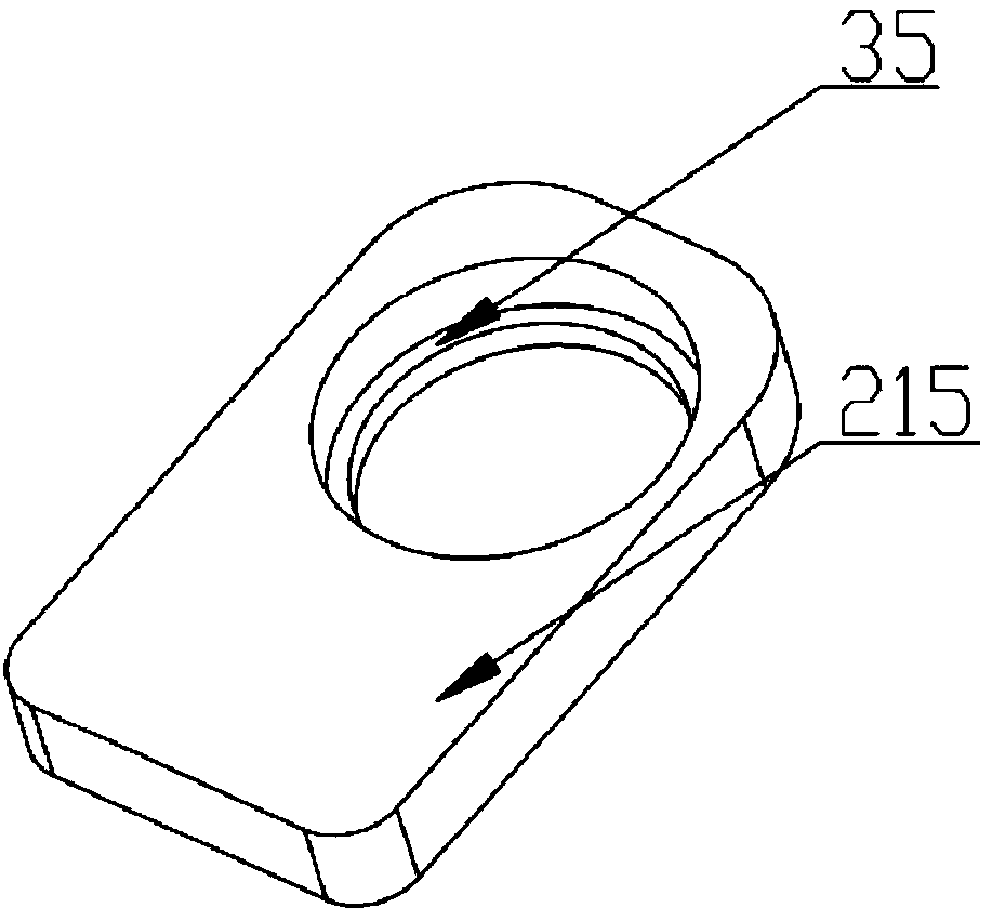

[0041] The invention provides a center powder feeding laser cladding head, which realizes center powder feeding laser cladding by combining multiple laser beams in space. From figure 1 It can be seen that this embodiment mainly includes a laser output head 1, a main body frame 2, a positioner 3, a gas nozzle 4, a water cooling nozzle 5, a connector 6, a powder feeding pipe 22, a protective lens holder 215, and a protective lens 35;

[0042]There are 2 or more laser output heads 1. In this embodiment, 4 laser output heads are used as an example for illustration; the main body frame 2 is provided with 4 laser channels 24 along the beam direction, and the laser channels 24 and the laser output heads 1 Corresponding to the same axis; the central position of the main frame 2 has a central through hole 25; the central through hole 25 verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com