Fuzzy intelligent decomposition-coordination extreme response surface method of reliability optimization design

A technology of decomposition, coordination and optimization design, applied in multi-objective optimization, calculation, CAD numerical modeling, etc., can solve problems such as poor engineering practicability, and achieve the effect of convenient actual analysis and calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

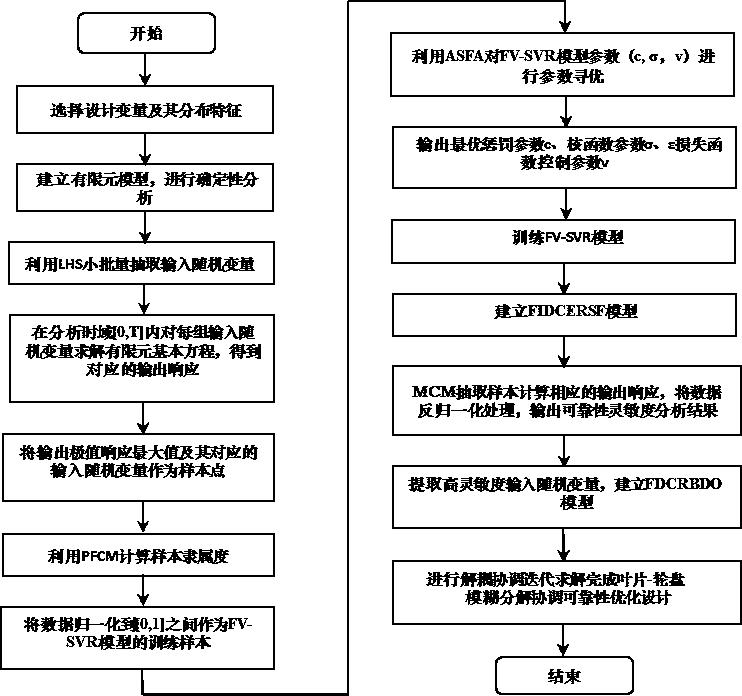

[0019] A fuzzy intelligent decomposition coordinated extreme value response surface method for reliability optimization design, comprising the following steps:

[0020] a. Obtain the output responses of the blades and discs under their respective failure modes through thermal-structural coupling deterministic analysis;

[0021] b. Construct fuzzy decomposition coordination extreme value response surface function (FIDCERSF);

[0022] c. Using MCM for dynamic reliability sensitivity analysis;

[0023] d. Establish fuzzy decomposition coordination reliability optimization design model (FDCRBDO).

Embodiment 2

[0025] According to the fuzzy intelligent decomposition coordination extreme value response surface method of the reliability optimization design described in embodiment 1, in the described step a, the density, temperature, aerodynamic pressure, elastic modulus, and thermal expansion coefficient of the blade-disc are used as input Random variables, find the maximum stress point, maximum creep strain point, minimum life point, maximum crack J integral point of the blade and the maximum stress point, maximum creep strain point, minimum life point of the wheel through deterministic analysis, and combine aviation Engine GH4133B alloy fatigue-creep damage relational formula, comprehensive equation of creep enduring thermal strength parameters, and Miner's linear cumulative damage rule to calculate blade-disc creep damage, fatigue damage, and creep enduring life.

Embodiment 3

[0027] According to the fuzzy intelligent decomposition coordination extreme value response surface method of the reliability optimization design described in embodiment 1, in the described step b, consider the fuzziness and randomness of the data, use the above-mentioned input variable as the input random variable, and use the Latin super Cubic sampling technique (LHS) extracts input random variable samples, solves the finite element basic equation for each sample, and obtains the corresponding stress, creep strain, low cycle fatigue life, crack J integral, creep damage, fatigue damage, and creep durability For the output response of life in the analysis time domain, all the maximum values of the dynamic output response in the analysis time domain and their corresponding input random variables are used as sample points, and the Possibilistic fuzzy c-means clustering algorithm (Possibilistic fuzzy c-means clustering, PFCM) calculates the membership degree of the sample, norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com