Integrated-form water-cooling power battery shell used for new energy automobiles

A new energy vehicle, power battery technology, applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of short circuit of power battery system, complex manufacturing process, high processing cost, and improve strength and stone-strike resistance. , The effect of reducing the short circuit of the module and good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

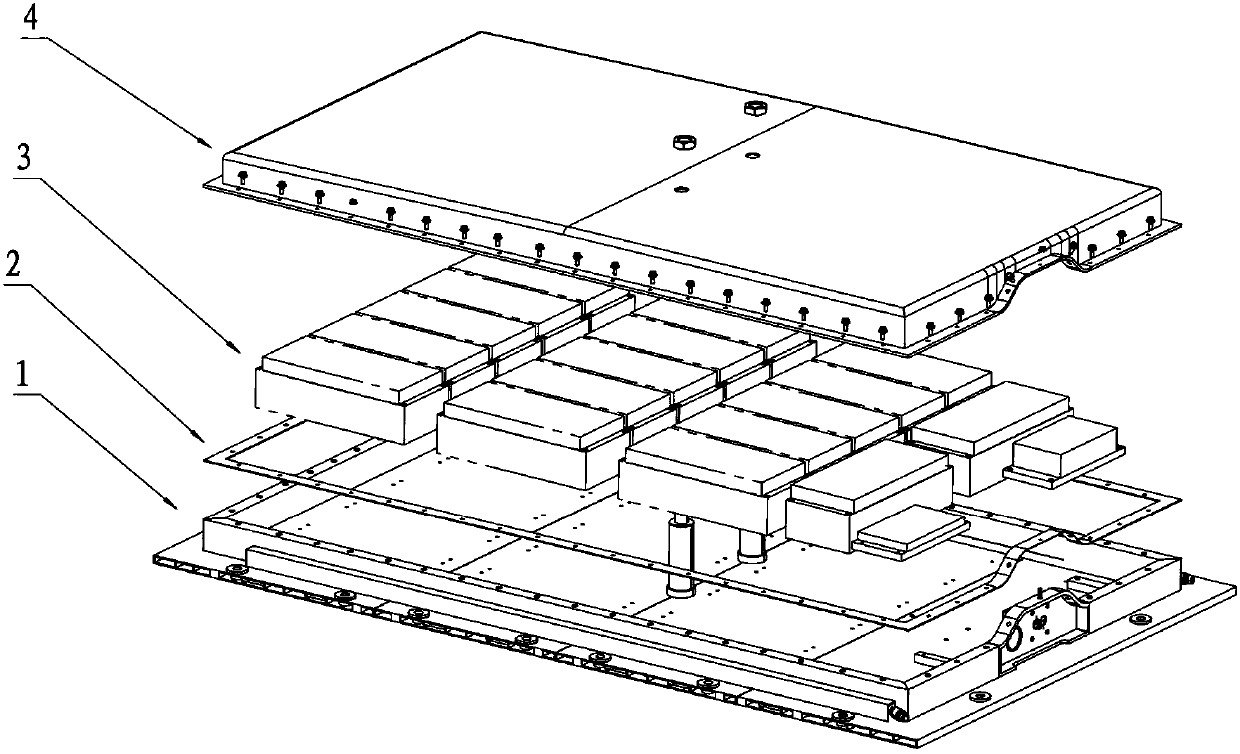

[0023] See figure 1 The present invention includes an upper casing 4 and a lower casing 1, and the battery module 3 is installed at the lower casing. The upper shell is made of SMC material molding process. The upper casing of the battery is installed on the lower casing by pressing the sealing gasket 2 by the locking screw, and the sealing gasket is pressed to ensure good sealing of the battery casing.

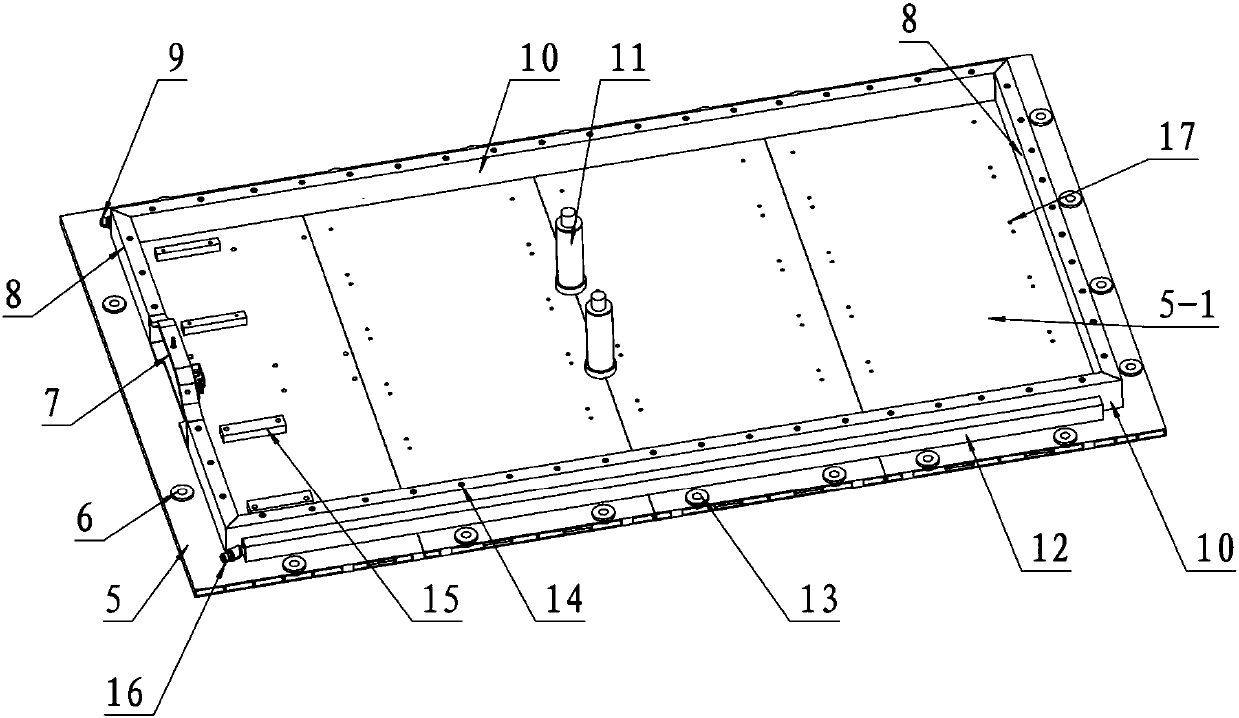

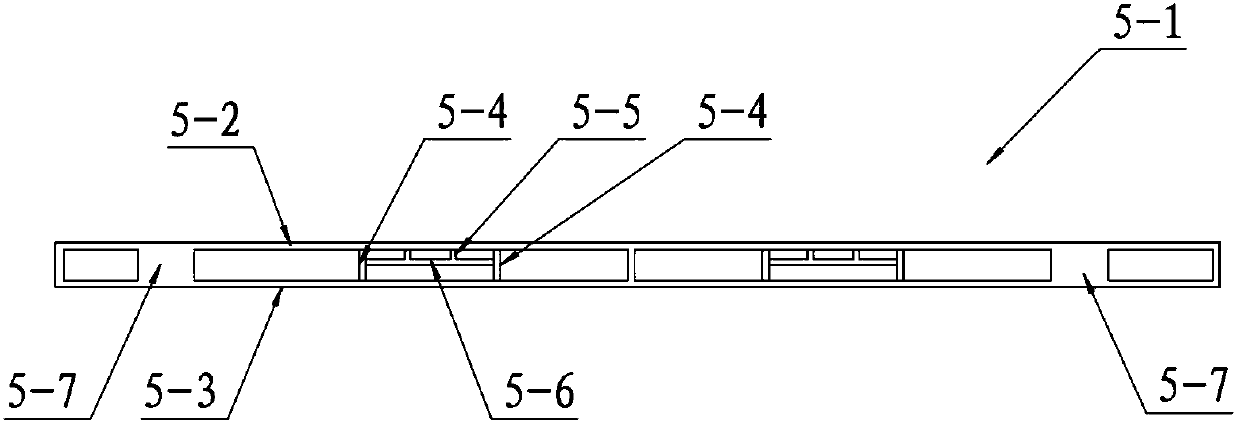

[0024] See Figure 2-4 The lower shell of the present invention is made of aluminum alloy profiles with a yield strength of 300 MPa and a tensile strength of 350 MPa. The lower shell includes a bottom plate and a side plate, and the bottom plate and the side plate are made of extruded aluminum alloy profiles. The bottom plate 5 is rectangular, and the bottom plate is composed of an upper bottom plate 5-2 and a lower bottom plate 5-3 to form a double-layer structure, and vertical ribs 5-4 are evenly distributed between the upper and lower bottom plates. The double-layer struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com