Lithium battery cell active pre-rolling method and apparatus

A lithium battery, active technology, applied in secondary batteries, non-aqueous electrolyte batteries, circuits, etc., can solve problems such as poor cell performance, low cell quality rate, cell deformation, etc., to improve market competitiveness, The effect of improving the good rate and eliminating tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

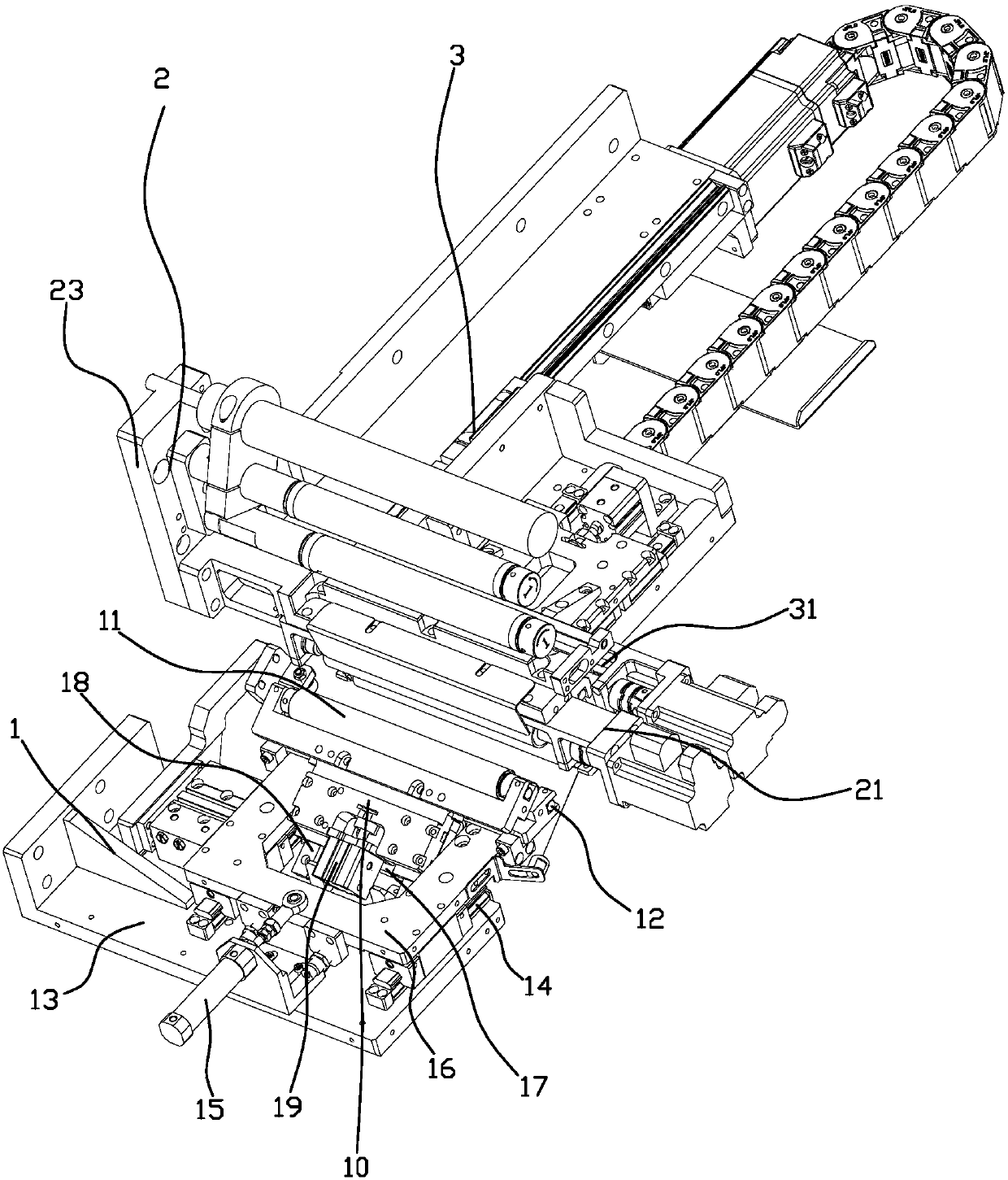

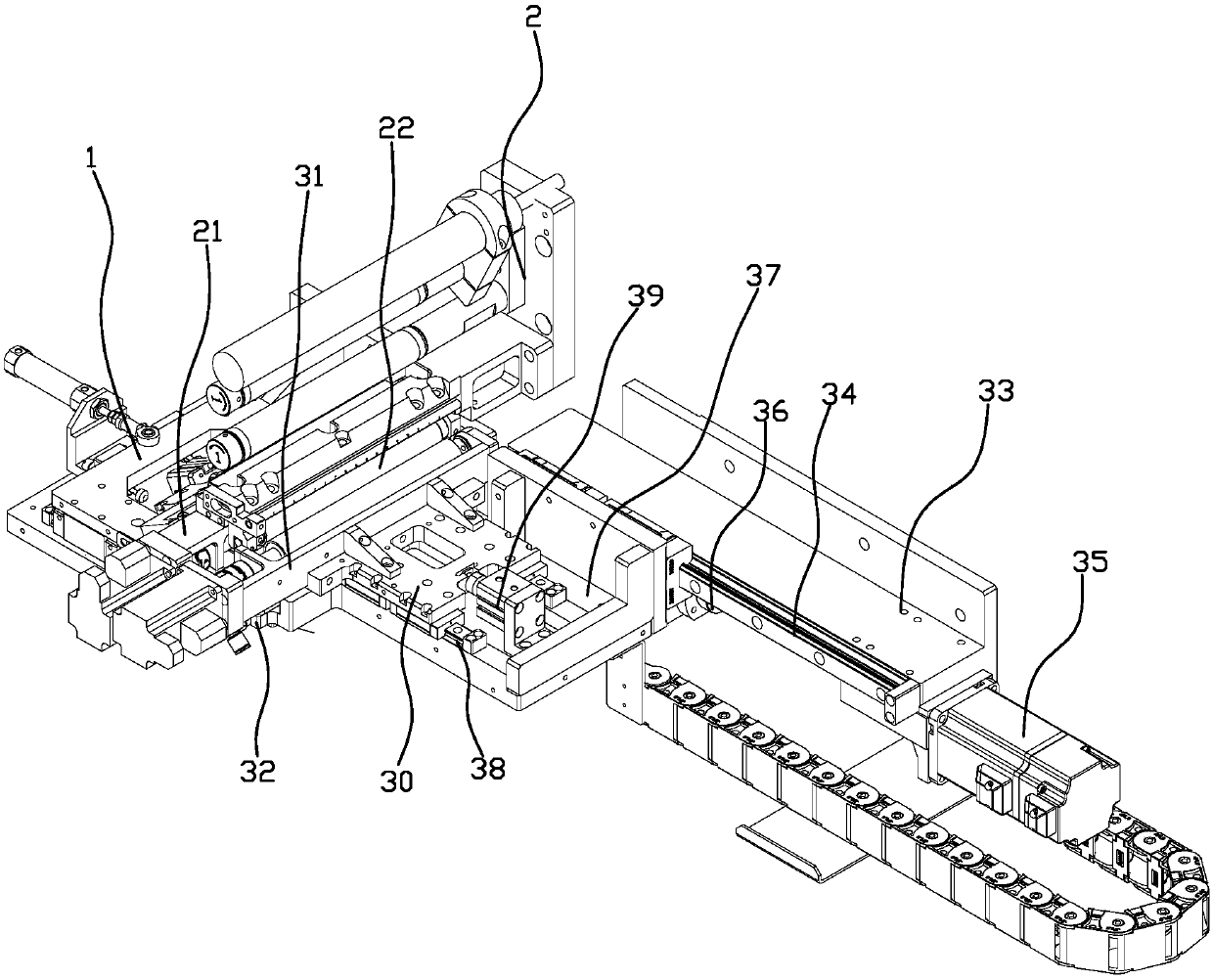

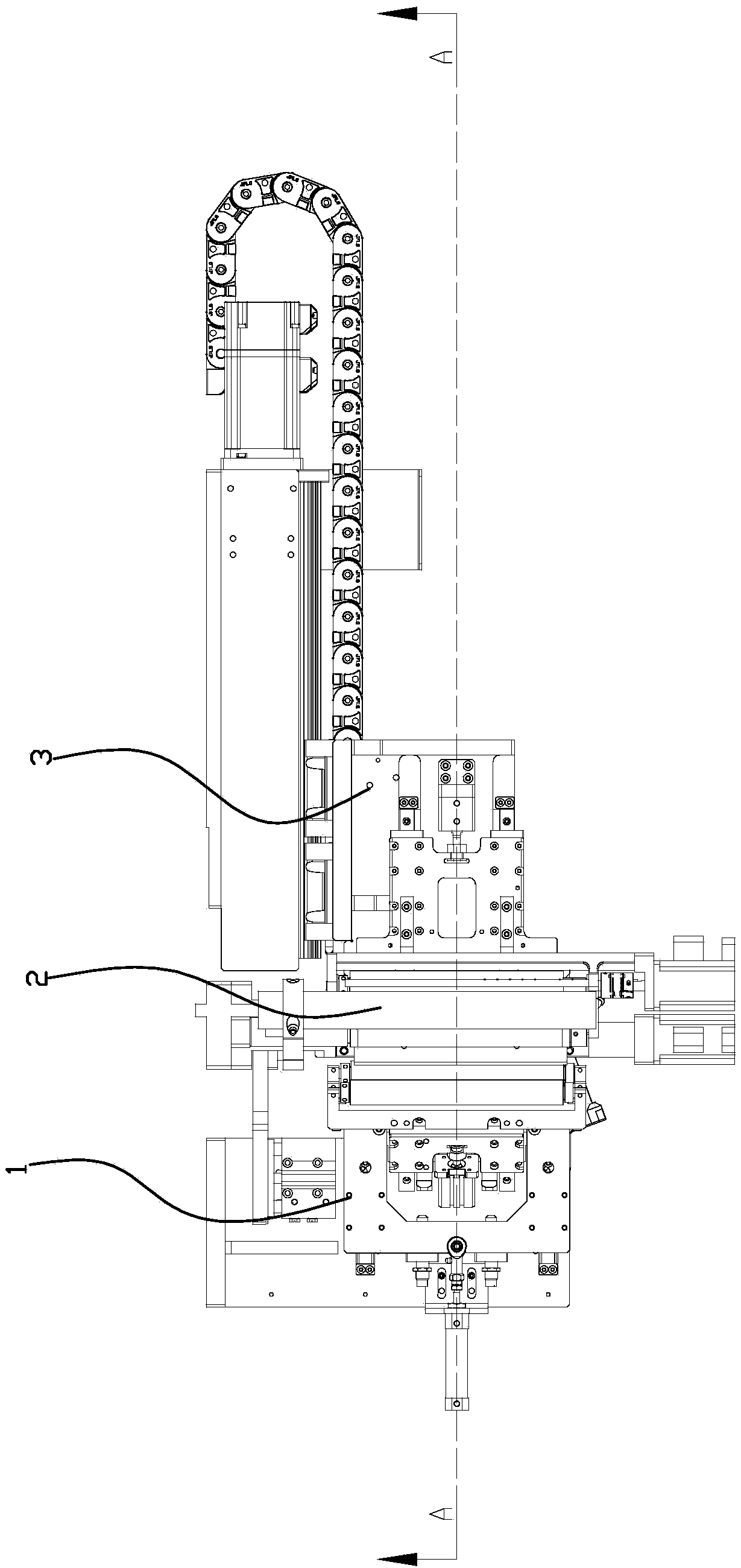

Image

Examples

Embodiment 1

[0043] Embodiment 1: In this embodiment, the data collected in step 1 is the rotation angular velocity of the negative electrode sheet feeding driving roller 213 and the positive electrode sheet feeding driving roller 313, and then establish the relationship between angular velocity and time, and further pass in step 3 The negative electrode sheet feeding drive motor 211 and the positive electrode sheet feeding drive motor 311 provide driving force to the negative electrode sheet feeding drive roller 213 and the positive electrode sheet feeding drive 313 respectively, and the negative electrode sheet feeding driving roller 213 and the positive electrode sheet feeding drive The drive 313 actively rotates according to the associated angular velocity, so that the rotational angular velocity of the negative electrode sheet feeding drive roller 213 and the positive electrode sheet feeding drive 313 are consistent with the collected data, thereby avoiding the deformation of the lower ...

Embodiment 2

[0044] Embodiment 2: In this embodiment, the data collected in step 1 is the tension of the upper diaphragm 41 and the lower diaphragm 42, and then the relationship between the tension and time is established, and further in step 3, the motor is driven by feeding through the negative electrode sheet 211 and the positive electrode sheet feeding drive motor 311 provide driving force to the negative electrode sheet feeding drive roller 213 and the positive electrode sheet feeding drive 313 respectively, and the negative electrode sheet feeding driving roller 213 and the positive electrode sheet feeding drive 313 are based on the associated tension. Actively provide an active torque that can offset the tension, thereby avoiding the deformation of the lower diaphragm 41 and the upper diaphragm 42, and helping to improve the quality of pre-rolling and the production quality of the battery cell.

[0045] Based on the above-mentioned active pre-rolling method for lithium battery cells,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com