High-stability supersonic transducer and its making process

An ultrasonic transducer, a high-stability technology, applied in the generation or transmission of acoustic or ultrasonic mechanical vibrations, in the field of sub-acoustic frequencies, can solve the problem of uneven center and edge of the front vibration block and rear vibration block, low tensile strength, The overall rigidity of the transducer is low, so as to improve the overall rigidity, power and stability, improve the tensile strength and fatigue strength, and improve the overall rigidity and conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

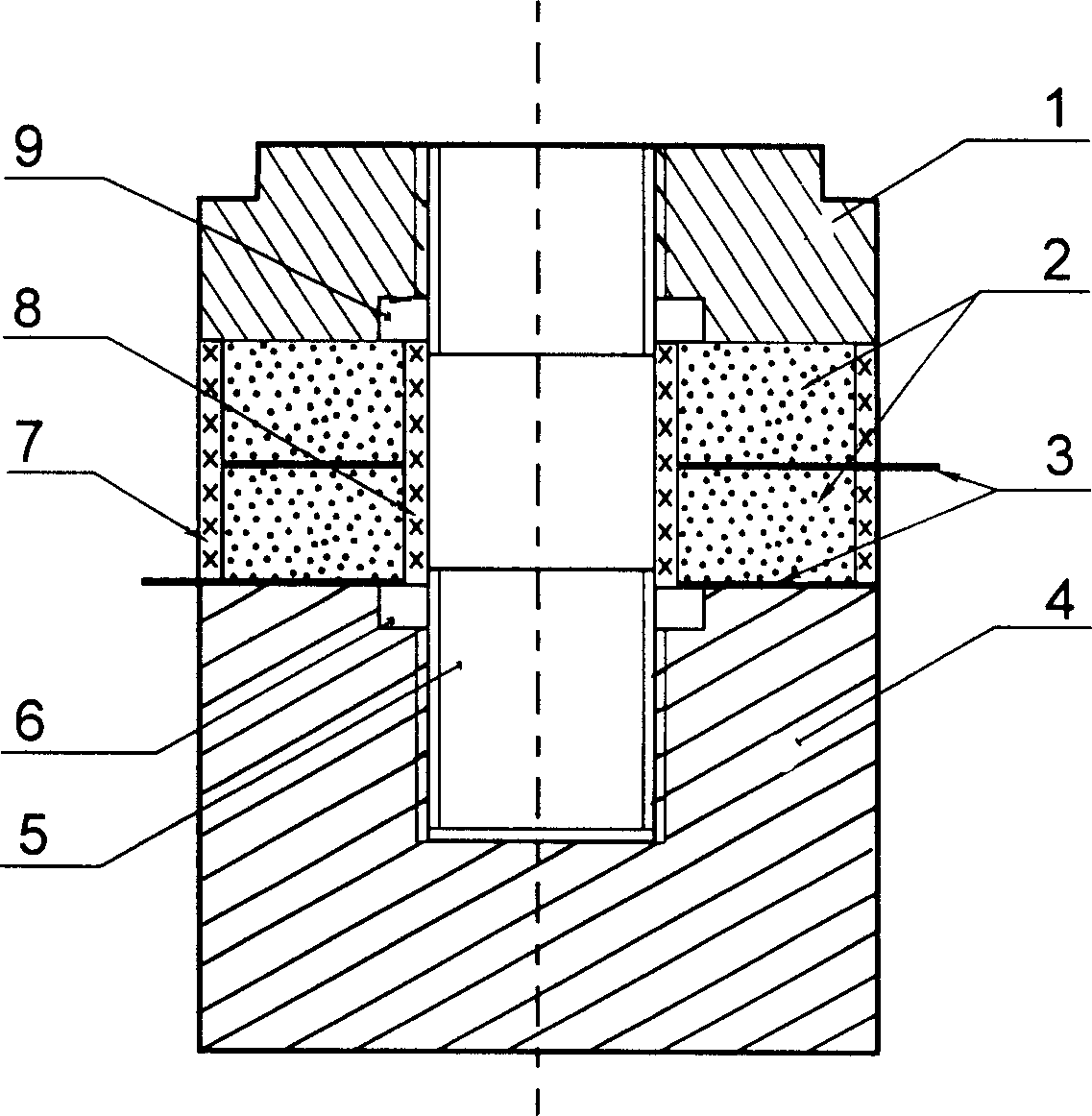

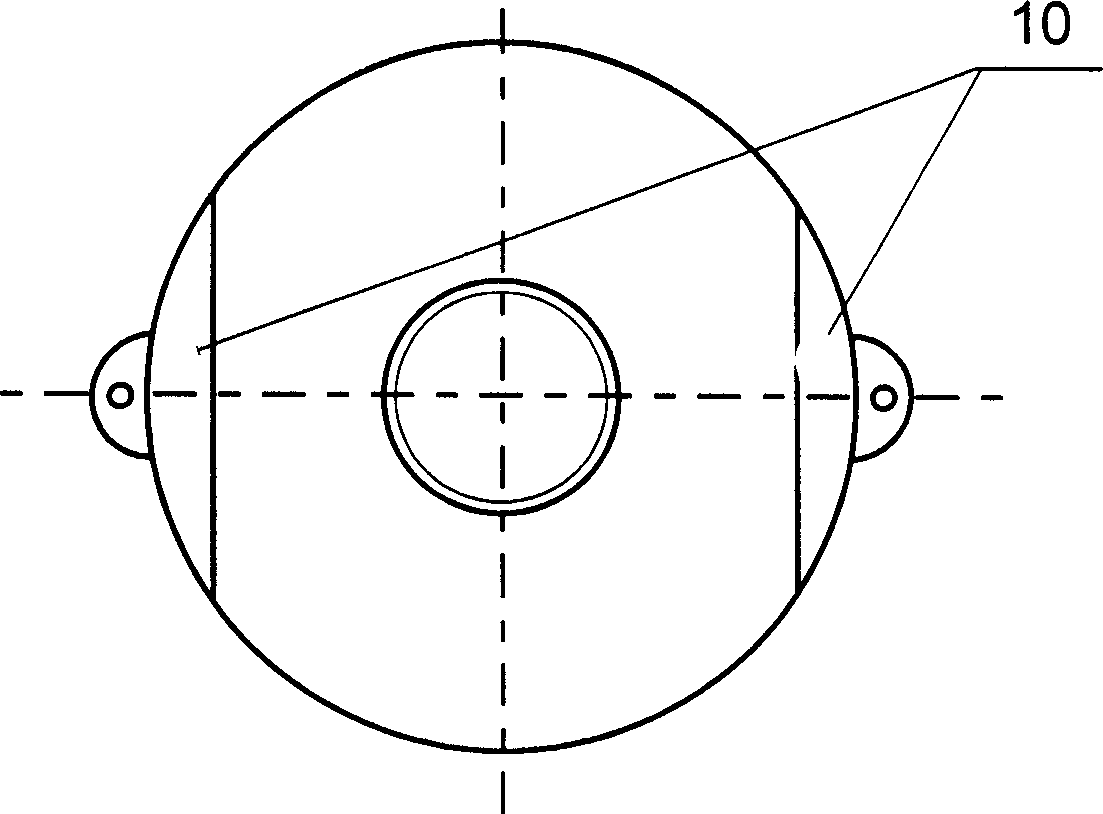

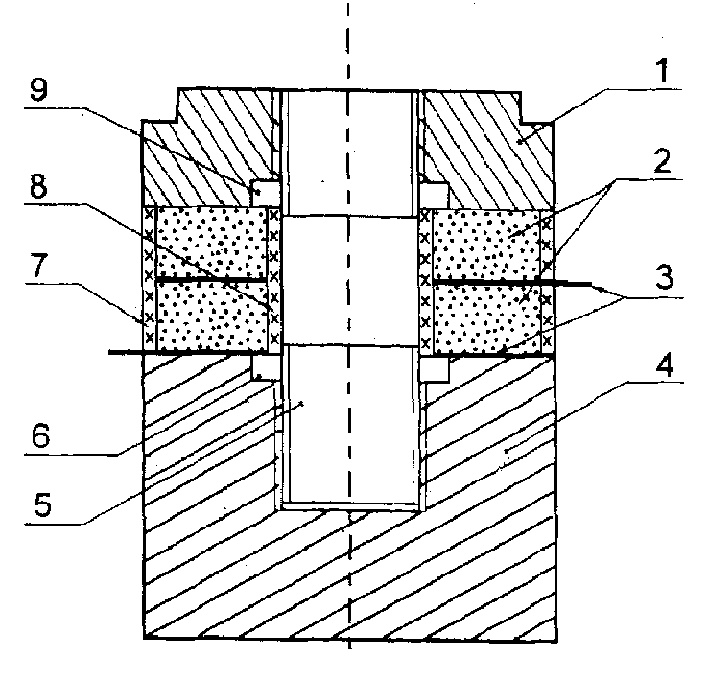

[0016] exist figure 1 , 2 Among them, the high-stability ultrasonic transducer of the present embodiment is connected by rear vibrating block 1, piezoelectric ceramic sheet 2, electrode sheet 3, front vibrating block 4, stud bolt 5, 705 silicone rubber layer 7, and insulating ring 8 Composition, 705 silicone rubber layer 7 is an embodiment of waterproof protective layer.

[0017] The stud bolt 5 of the present invention is a fine thread stud bolt, an insulating ring 8 is set on the periphery of the stud bolt 5, and two piezoelectric ceramic sheets 2 are set on the periphery of the insulating ring 8, and the two piezoelectric ceramic sheets 2 An electrode sheet 3 is installed between them, the rear vibration block 1 is installed at the rear end of the stud bolt 5, the front vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com