Restore method of liquid-state metal battery

A technology of a liquid metal battery and a repair method, applied in the field of energy storage, can solve the problems of waste of liquid metal batteries, reduce the difficulty and cost of operation and maintenance of battery stacks, etc., so as to reduce the difficulty and cost of operation and maintenance, save battery costs, and reduce battery wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

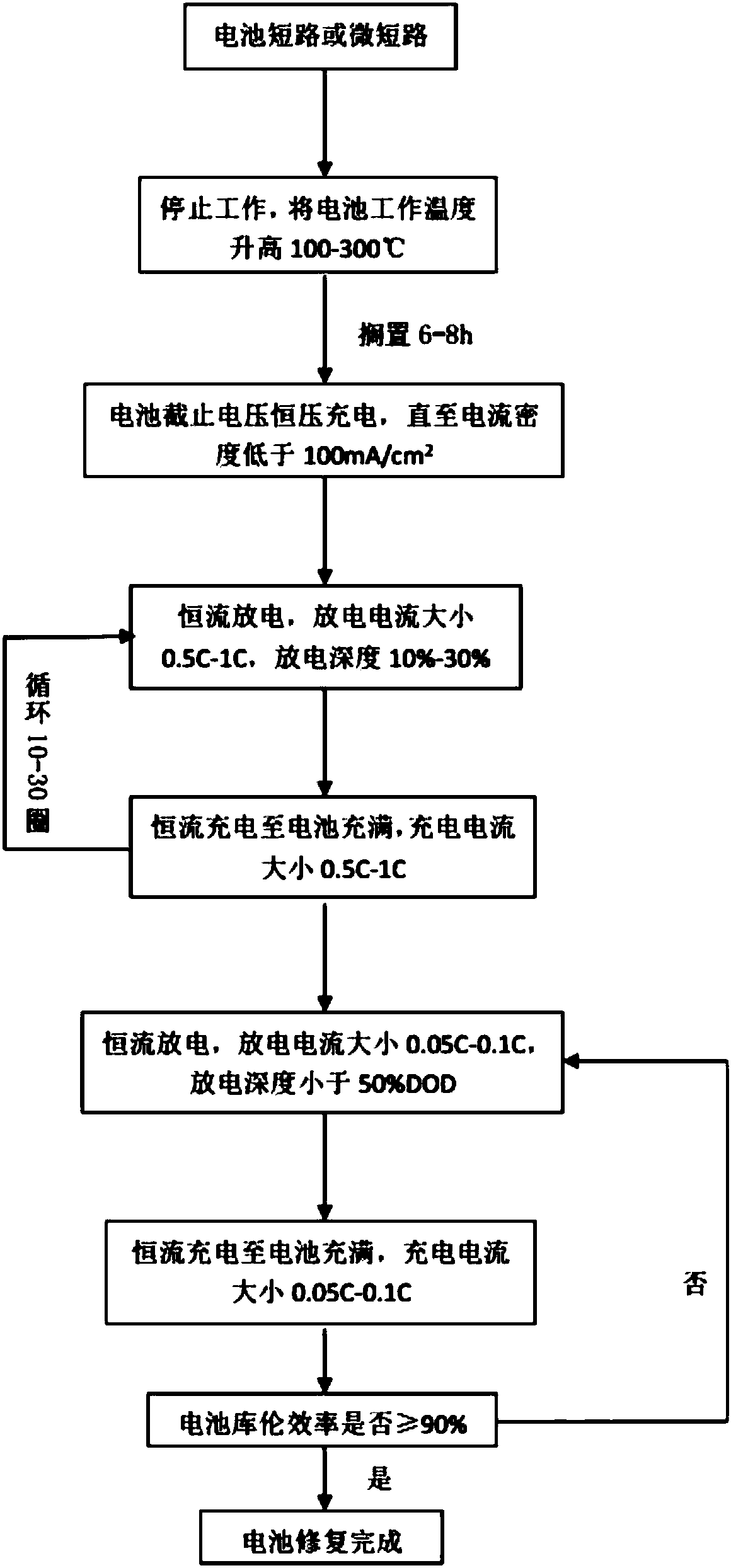

[0048]Adopt the present invention to repair short-circuited Li / Pb liquid metal battery (operating temperature 350 ℃, cut-off voltage 0.9V), repair method mainly comprises the following steps:

[0049] (1) Stop the battery and raise the battery temperature to 450°C;

[0050] (2) Leave the battery at 450°C for 6 hours;

[0051] (3) Charge the battery at a constant voltage of 0.9V;

[0052] (4) The current density of the battery is lower than 100mA / cm 2 Then turn to constant current discharge, the discharge current is 0.5C, and the discharge depth is 10% DOD;

[0053] (5) After discharging, charge the battery with a constant current until it is fully charged, and the charging current is 0.5C;

[0054] (6) Go to step (4), and cycle 10 times like this;

[0055] (7) Discharge the battery with a constant current, the discharge current is 0.05C, and the discharge depth is 10% DOD;

[0056] (8) Charge the battery with a constant current until it is fully charged after discharge, a...

Embodiment 2

[0060] Using the present invention to repair micro-short-circuit Li-Sn / Sb liquid metal batteries (working temperature 450°C, cut-off voltage 1.2V), the repair method mainly includes the following steps:

[0061] (1) Stop the battery and raise the working temperature of the battery to 650°C;

[0062] (2) Leave the battery at 650°C for 7 hours;

[0063] (3) Charge the battery at a constant voltage of 1.2V;

[0064] (4) The current density of the battery is lower than 100mA / cm 2 Then turn to constant current discharge, the discharge current is 0.75C, and the discharge depth is 20% DOD;

[0065] (5) After discharging, charge the battery with a constant current until it is fully charged, and the charging current is 0.75C;

[0066] (6) Go to step (4), so circulate 15 times;

[0067] (7) Discharge the battery with a constant current, the discharge current is 0.075C, and the discharge depth is 30% DOD;

[0068] (8) After discharging, charge the battery with a constant current unt...

Embodiment 3

[0072] Using the present invention to repair micro-short-circuit Li-Pb / Sb liquid metal batteries (working temperature 500°C, cut-off voltage 1.1V), the repair method mainly includes the following steps:

[0073] (1) Stop the battery and raise the working temperature of the battery to 800°C;

[0074] (2) Leave the battery at 800°C for 8 hours;

[0075] (3) Charge the battery at a constant voltage of 1.1V;

[0076] (4) The current density of the battery is lower than 100mA / cm 2 Then turn to constant current discharge, the discharge current is 0.75C, and the discharge depth is 25% DOD;

[0077] (5) After discharging, charge the battery with a constant current until it is fully charged, and the charging current is 0.75C;

[0078] (6) Go to step (4), so cycle 20 times;

[0079] (7) Discharge the battery with a constant current, the discharge current is 0.075C, and the discharge depth is 35% DOD;

[0080] (8) After discharging, charge the battery with a constant current until i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com