Method and device for controlling four-quadrant rectifier of locomotive traction converter

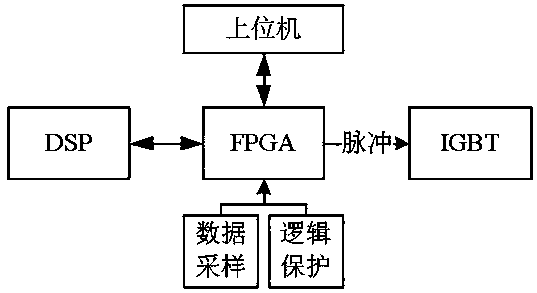

A four-quadrant rectifier and traction converter technology, which is applied in the direction of control of electromechanical transmission, motor generator control, output power conversion device, etc., can solve the problems of large amount of calculation and low control accuracy, and achieve error-free tracking , the control logic is satisfied, the effect of complete communication and protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The four-quadrant rectifier control method of the locomotive traction converter is realized by the following steps:

[0018] 1) Collect the grid side voltage, current and DC bus voltage of the locomotive traction converter;

[0019] 2) Obtain the phase and amplitude of the grid-side voltage according to the collected grid-side voltage;

[0020] 3) Set the bus command voltage, compare the bus command voltage with the collected DC bus voltage, and then form a bus voltage closed loop through the PI controller (that is, use the bus command voltage and the collected DC bus voltage as the input of the PI controller) ;

[0021] 4) The output of the PI controller is multiplied by the phase of the grid-side voltage to obtain the command current in the same phase as the grid-side voltage;

[0022] 5) After the command current is compared (differenced) with the collected grid-side current, it enters the PR controller;

[0023] 6) After the output of the PR controller is compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com