PCB rapid in heat dissipation

A fast, heat sink technology, applied in the direction of circuit heating devices, printed circuit components, electrical components, etc., can solve the problem of low heat dissipation performance of PCB, achieve the effect of improving heat dissipation performance, saving external space, and reducing overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

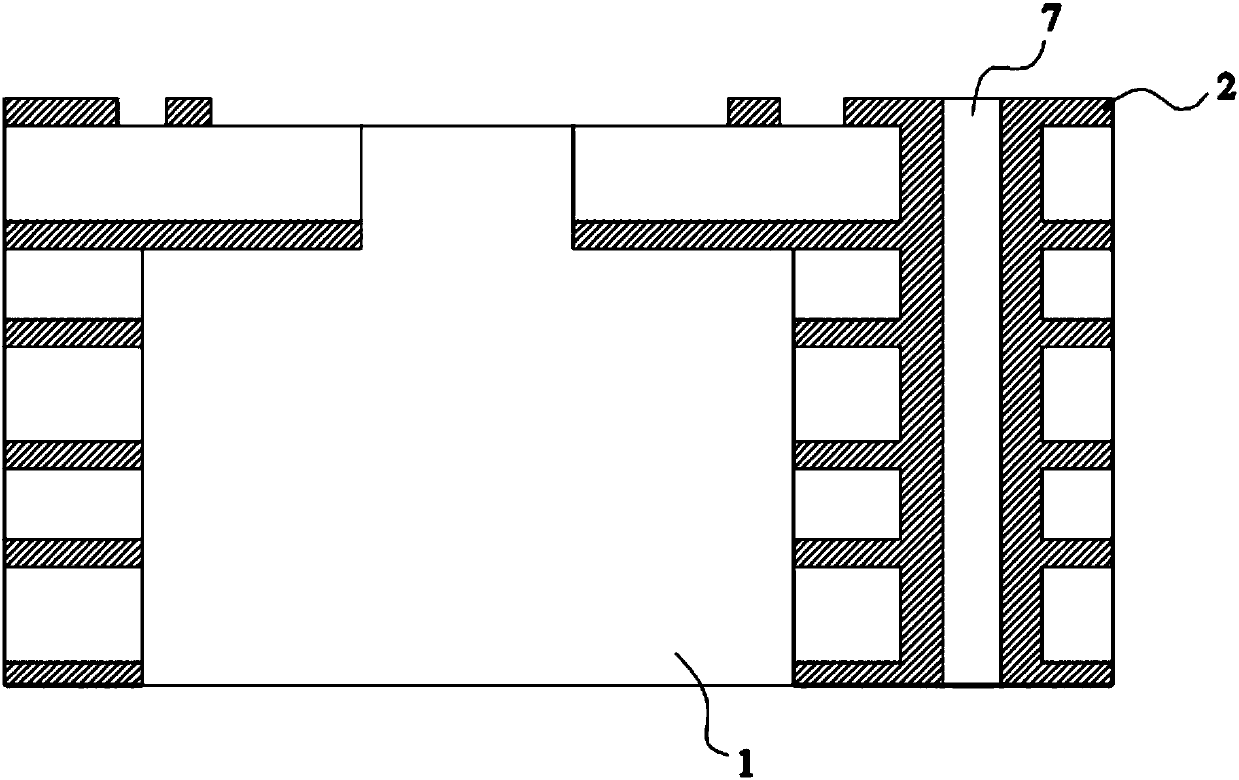

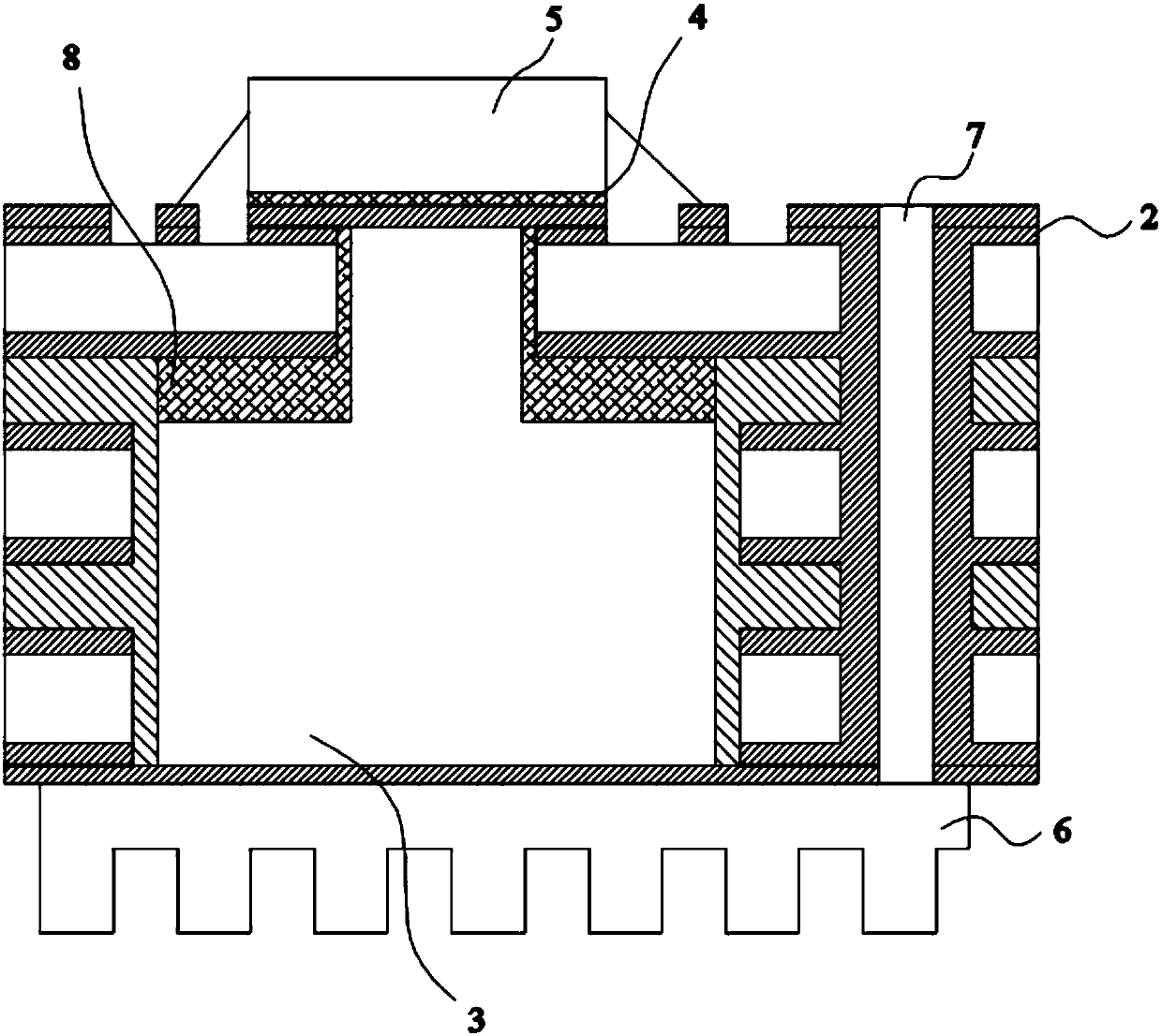

[0034] This embodiment provides a PCB with rapid heat dissipation, wherein the PCB is formed by pressing three core boards (but the number is not limited to this), and the schematic diagram of slotting on the PCB is as follows figure 1 shown. On the PCB, a stepped groove 1 is milled by a milling machine, and a via hole 7 is drilled by a drilling machine, wherein both are arranged along the thickness direction of the PCB, and the shoulder of the stepped groove 1 is connected to one of the metal layers 2 inside the PCB. Contour. The via hole 7 is electrically connected to the metal layer 2 of the PCB, and is a metallized hole. In addition, the top surface of the PCB is pre-installed with high-power components 5 , and the opening position of the stepped groove 1 corresponds to the bottom position of the pre-installed high-power components 5 .

[0035] The via hole 7 is provided to transfer the heat in the metal layer 2 inside the PCB to the via hole 7 to play the role of auxili...

Embodiment 2

[0050] This embodiment provides another PCB with rapid heat dissipation. Its cross section is Figure 5 As shown, for the sake of simplicity, only the differences between Embodiment 2 and Embodiment 1 are described. The difference is:

[0051] In this embodiment, the structure of the stepped high thermal conductivity metal block 3 and the heat sink 6 is combined, that is, the sheet structure on the heat sink 6 is arranged on the stepped high thermal conductivity metal block 3, so that the stepped high thermal conductivity metal block 3 is Evenly distributed flake structure. Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

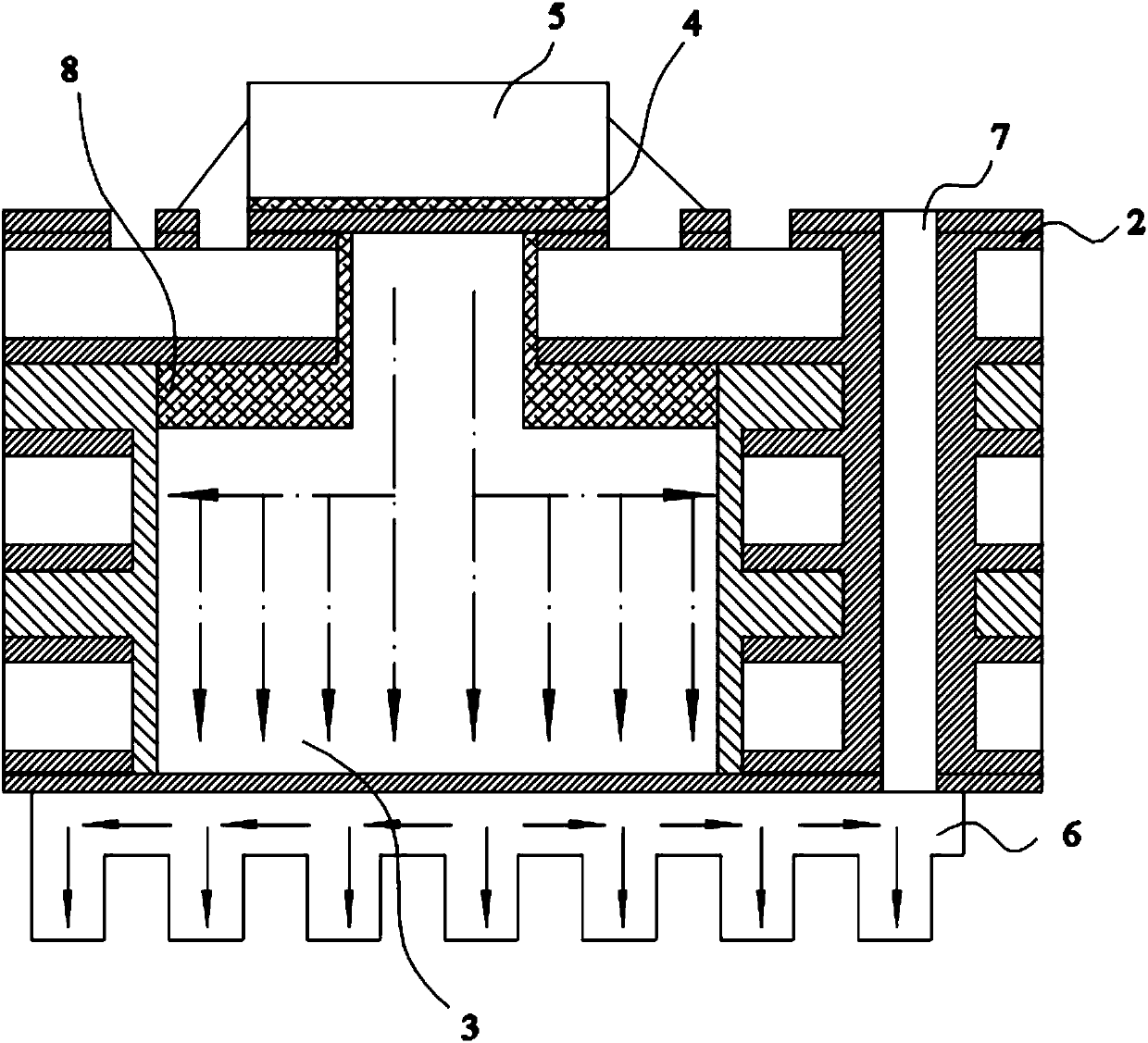

[0053] This embodiment provides a PCB with rapid heat dissipation, its cross-sectional view is as follows Figure 6 As shown, for the sake of simplicity, only the differences between Embodiment 3 and Embodiment 1 are described. The difference is:

[0054] The bottom surface of the stepped metal block 3 with high thermal conductivity protrudes from the bottom surface of the PCB, and the heat sink 6 is arranged close to the stepped metal block 3 with high thermal conductivity. Other structures are the same as those in Embodiment 1, and will not be repeated here.

[0055] In the known structure, after adopting the heat conduction metal layer 2, the heat is conducted to the air by the heat sink 6, however, the more media the generated heat passes through, the less heat the heat sink 6 dissipates. The medium of spreading scriptures will absorb most of the heat, but cannot dissipate it. Therefore, the structure in this embodiment can dissipate heat more quickly and directly.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com