Hybrid atmospheric water generator

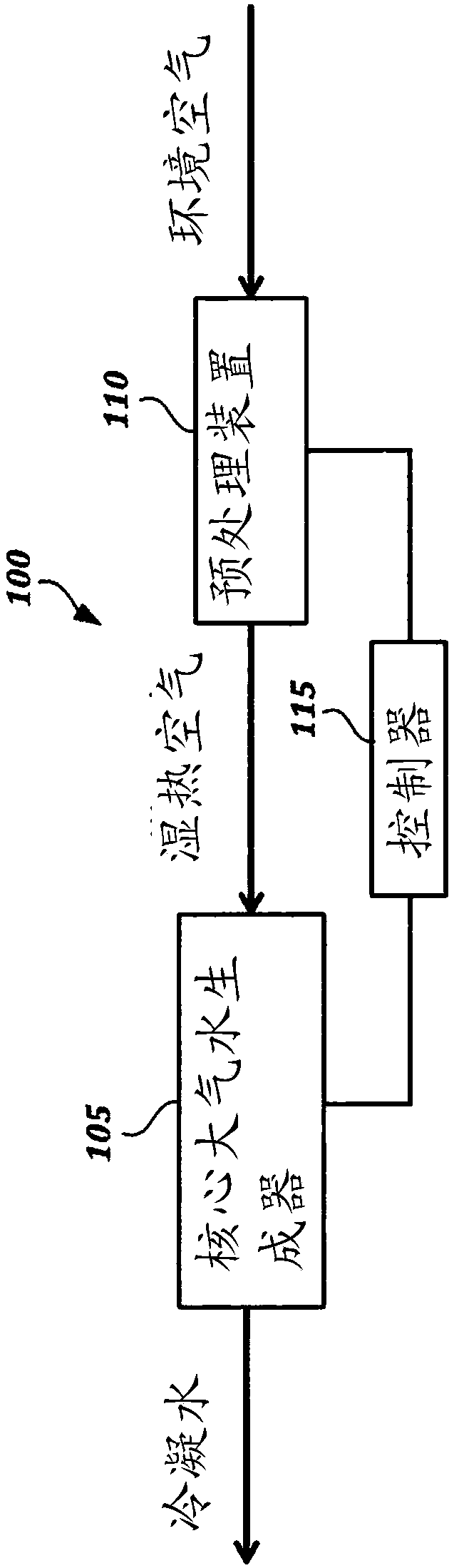

A generator, atmospheric technology, applied in key feature areas of the subject, that addresses issues such as water production and performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

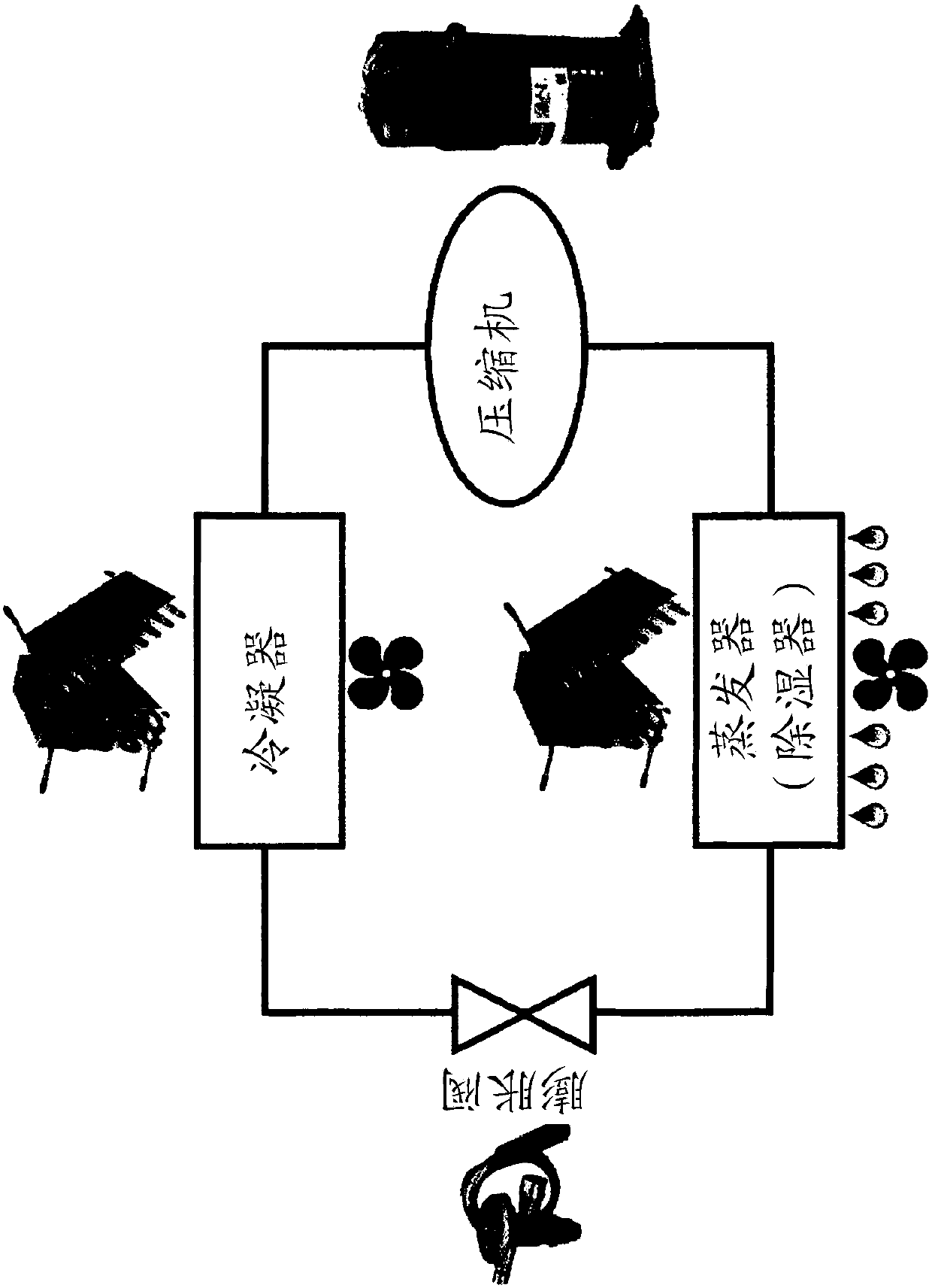

[0119] Example 1: Performance of a Commercial AWG

[0120] We tested and simulated the performance of two highly efficient existing AWG units using different operating conditions. Two typical residential-scale and commercial-scale AWG units on the market have been thoroughly studied. The water generation rate and power consumption of the units were measured to calculate their performance using various measurement equipment including temperature and humidity sensors, digital clamp meters and anemometers. The residential installation is linked to an environmental chamber at the Laboratory for Alternative Energy Conversion (LAEC) at Simon Fraser University in British Columbia, Canada, to simulate a variety of realistic operating conditions. Environmental chambers can provide many different temperatures and humidity at the inlet of a residential AWG unit, allowing us to evaluate the performance of the unit under different operating conditions. Our measurement results are shown...

example 2

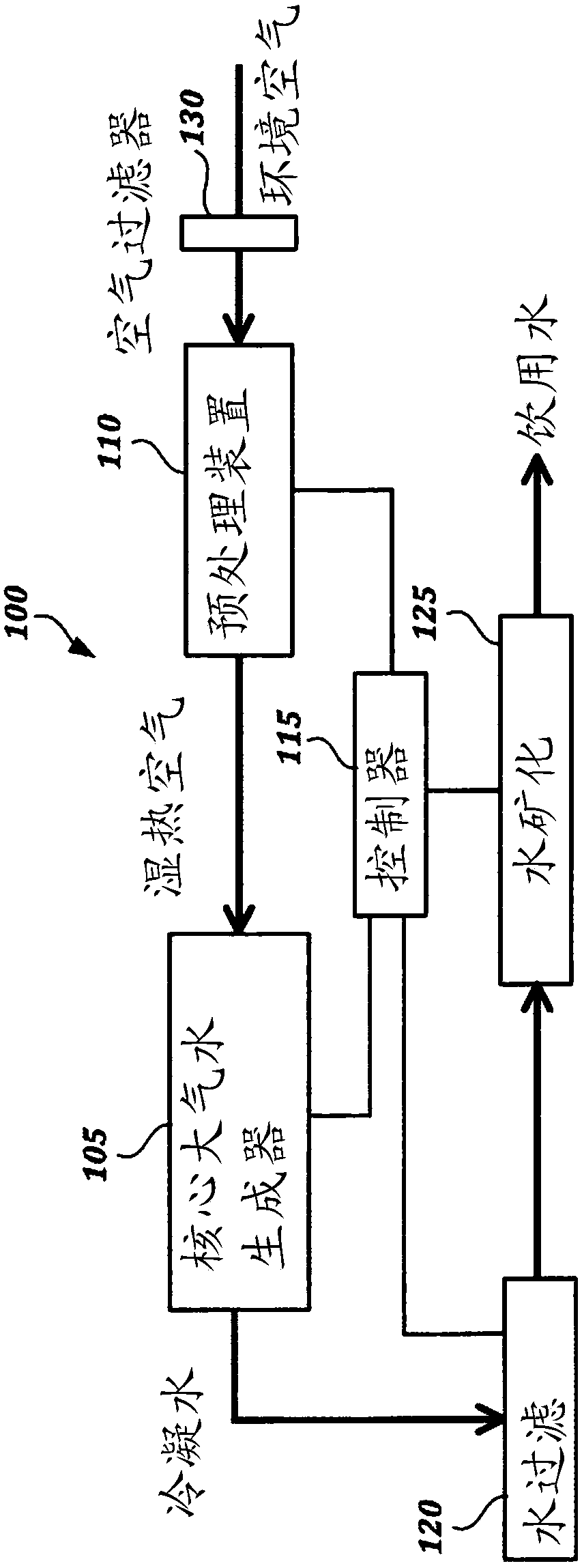

[0129] Example 2: Prototype HAWG according to embodiments disclosed herein

[0130] Build the HAWG according to the published parameters. Figure 8 is a 3D rendering of the design used for a representative HAWG, and Figure 9 is a photograph of an exemplary working packed bed HAWG according to our design, which is a prototype including an adsorption / desorption packed bed and a VCR unit. Because the VCR uses an electric chiller, this prototype would be classified as an EHAWG according to the terminology developed in this paper.

[0131] In an exemplary HAWG, too, air is blown through the system with a high efficiency variable speed fan connected to the inlet of the adsorption / desorption bed and the system is controlled by a control panel. During the adsorption step, the VCR is off while the fan blows air through the bed. In this step, the air flow is discharged from the bottom outlet (such as Figure 11 shown) and does not pass through the VCR unit. After the bed is comp...

example 3

[0134] Example 3: Performance of an Exemplary HAWG According to Embodiments Disclosed herein

[0135] We tested against various environmental conditions (using an environmental chamber) such as Figure 9 Performance of the prototype HAWG device shown, which exhibits significantly higher efficiency and water generation rate compared to existing AWG devices. Table 4 shows the performance comparison of a typical high-efficiency AWG device (manufactured by Dew Point, see previous section) on the market and a HAWG device under the same environmental conditions. For this comparison, the average ambient temperature and humidity in the British Columbia summer were selected. It should be pointed out that existing AWG devices cannot generate water in arid regions; however, since the air is always preconditioned before entering the VCR device, the performance of our HAWG does not depend on the environmental conditions. In other words, unlike existing AWG devices that do not work in d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com