Surface defect real-time detection device for additive manufacturing

A real-time detection and additive manufacturing technology, applied in the field of additive manufacturing, to achieve the effect of improving the detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the present invention will be further described below in conjunction with accompanying drawings and examples, but the implementation and protection of the present invention are not limited thereto. Achieved with technology.

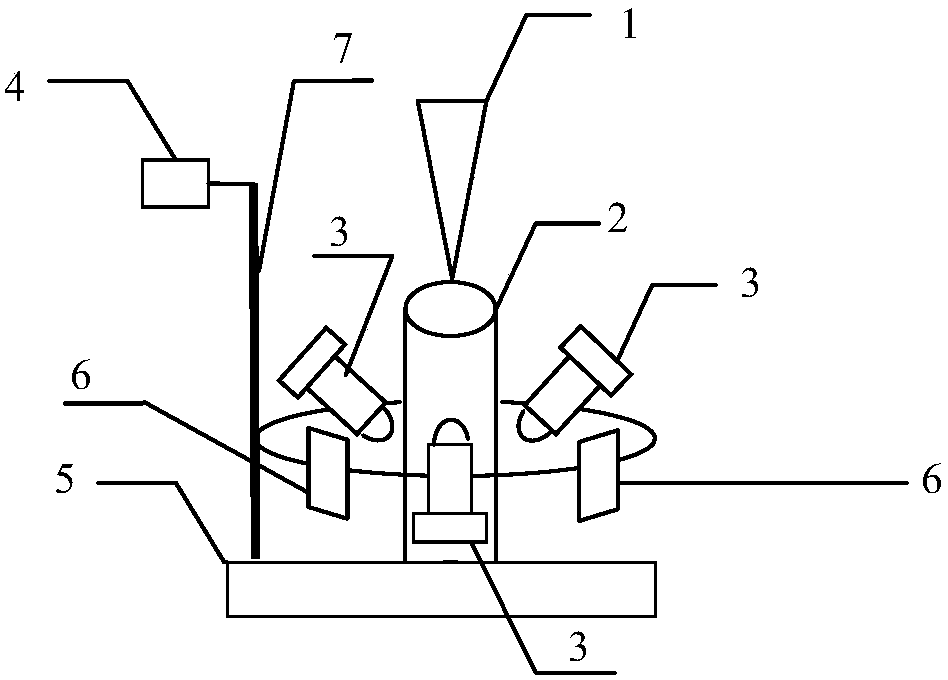

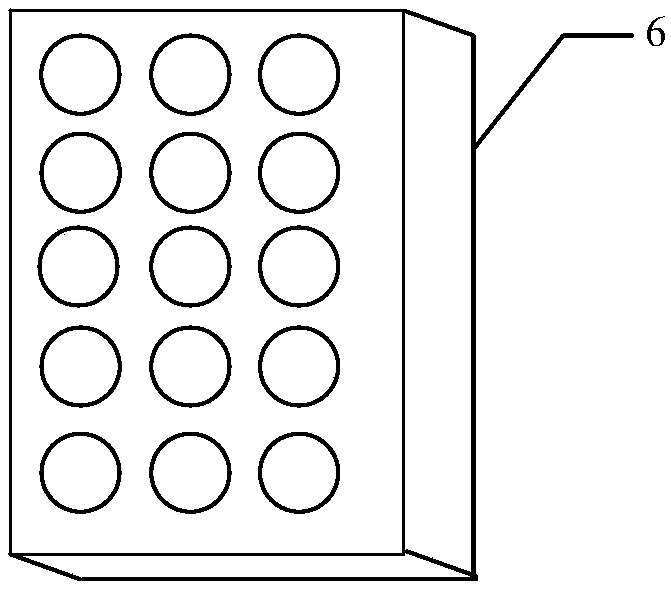

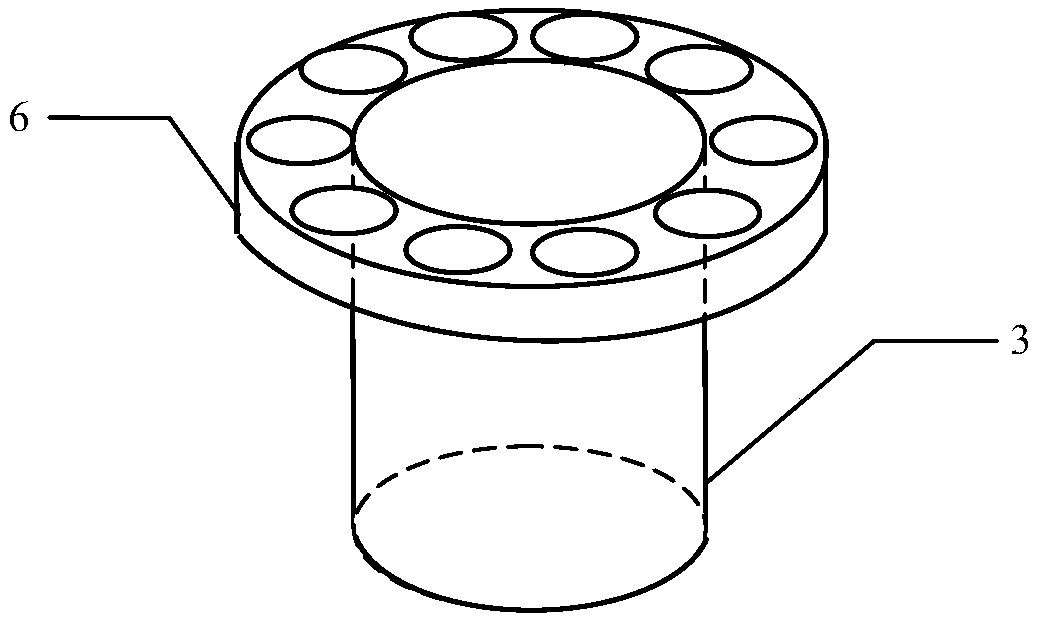

[0028] In this example, a device for real-time detection of surface defects of additive products consists of: an illumination module, a lens group, a sensor module, a transmission module and a computer processing unit. The lighting module is an LED light source and a switch control circuit, which works in the shooting process of the lens group; the lens group includes one or more ordinary optical lenses, and the computer processing unit fuses the images collected by the lens group after shooting, images for defect detection analysis. The transmission module includes a stepping motor, a screw or other mechanical devices and corresponding control circuits, which are used to change the height of the lens group, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com