Multispectral extra-large aperture telescope objective

A telescopic objective lens and multi-spectral technology, applied in the field of optical equipment, can solve the problems of limiting the use temperature range of the lens, glue hardening, glue opening, etc., and achieve the effects of widening the use temperature range, reducing weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

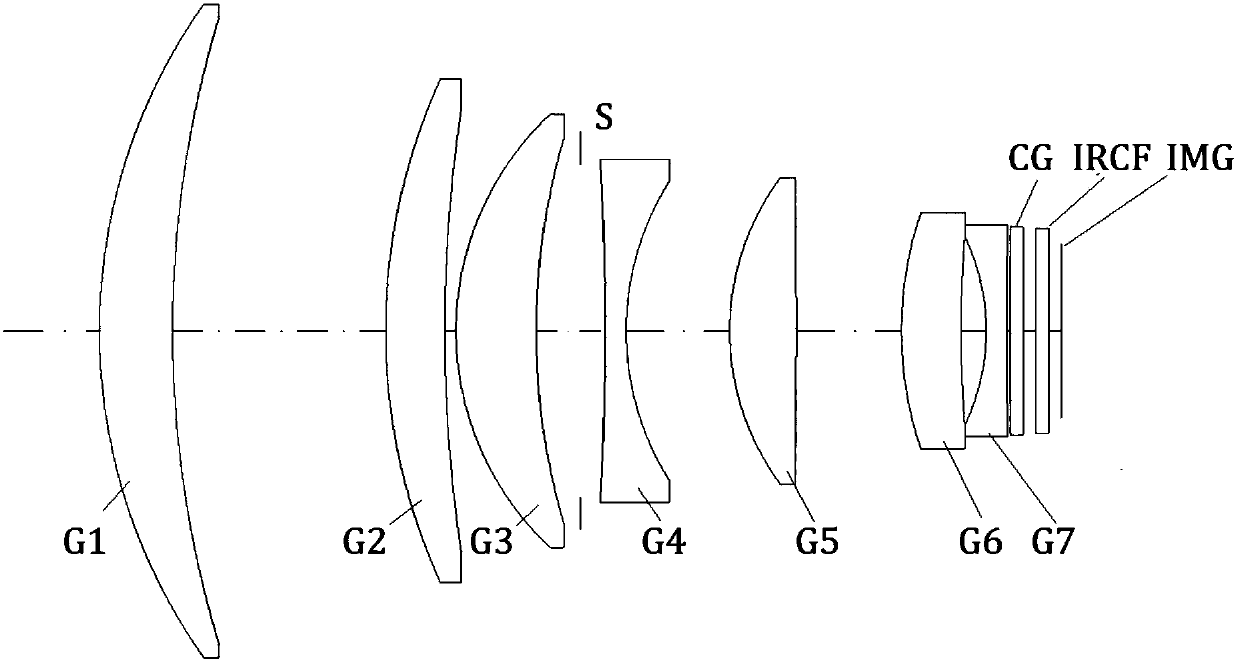

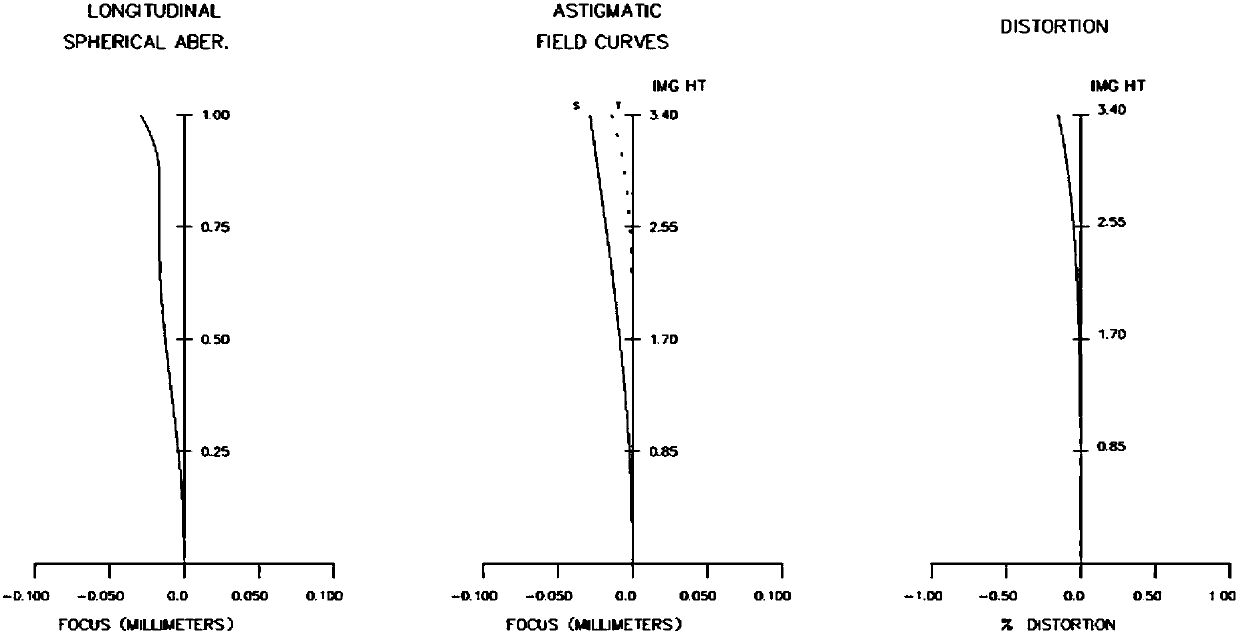

[0025] like figure 1 Shown is a sectional view along the optical axis of the telescopic objective lens of this embodiment. The telescopic objective lens is arranged in order from the object plane side to the image plane side along the incident direction of the light rays, a first lens, a second lens, a third lens, a diaphragm S, a fourth lens, a fifth lens, a sixth lens and The seventh lens, wherein: the first lens is a positive power lens G1 with a front convex and a concave back, the second lens is a positive power lens G2 with a front convex and a concave back, and the third lens is a positive power lens G3 with a front convex and a back concave , the fourth lens is biconcave negative power lens G4, the fifth lens is biconvex positive power lens G5, the sixth lens is positive power lens G6 with front convex and back concave, and the seventh lens is biconcave Negative power lens G7.

[0026] Preferably, a protective mirror CG is provided between the seventh lens and the im...

Embodiment 2

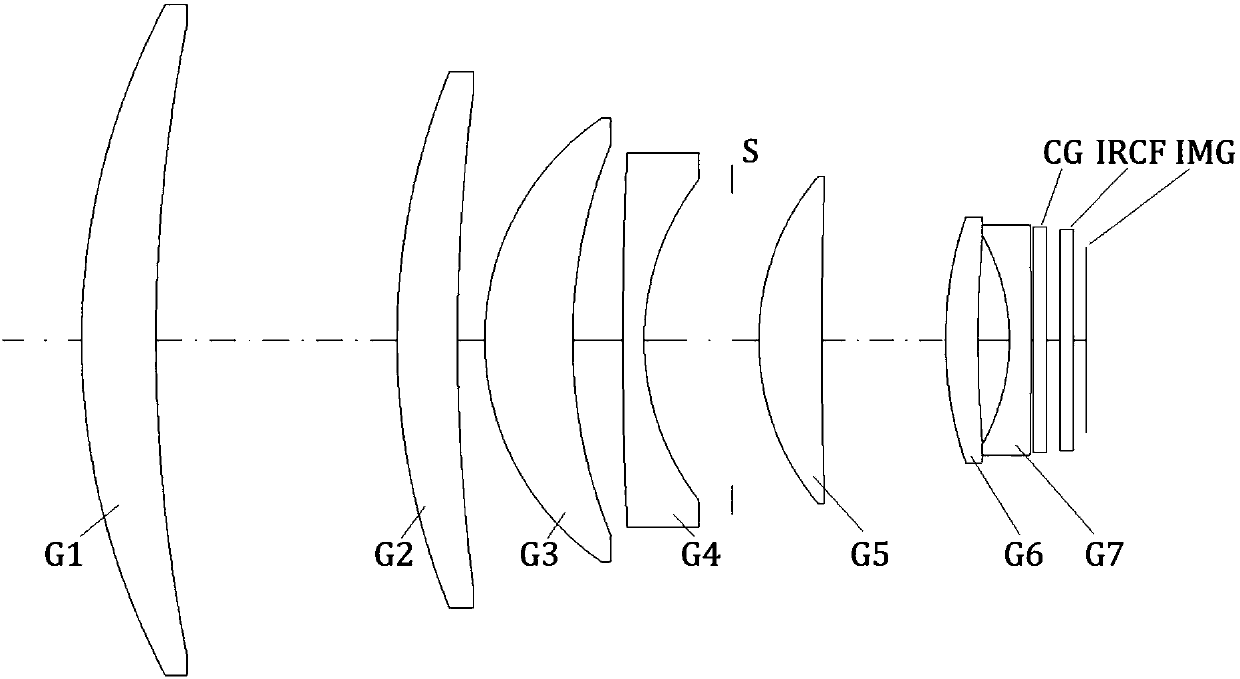

[0036] like image 3Shown is a sectional view along the optical axis of the telescopic objective lens of this embodiment. Compared with Embodiment 1, the diaphragm S in this embodiment is set between the fourth lens and the fifth lens, and the fourth lens is a negative power lens with front convex and rear concave, and the fifth lens is front convex and rear A concave positive power lens, and the seventh lens is a negative power lens with a front concave and a back convex.

[0037] The focal length ratio of the first lens and the optical system |f1 / f|=2.53, the focal length ratio of the second lens and the optical system |f2 / f|=3.70, the focal length ratio of the third lens and the optical system |f3 / f |=1.65, the focal length ratio of the fourth lens and the optical system |f4 / f|=0.49, the focal length ratio of the fifth lens and the optical system |f5 / f|=0.55, the focal length ratio of the sixth lens and the optical system |f6 / f|=0.87, the focal length ratio of the sevent...

Embodiment 3

[0043] like Figure 5 Shown is a sectional view along the optical axis of the telescopic objective lens of this embodiment. Compared with Embodiment 1, the diaphragm S in this embodiment is set between the fourth lens and the fifth lens, and the fifth lens is a positive power lens with front convex and back concave, and the seventh lens is front concave and back convex negative power lens.

[0044] The focal length ratio of the first lens and the optical system |f1 / f|=2.45, the focal length ratio of the second lens and the optical system |f2 / f|=3.11, the focal length ratio of the third lens and the optical system |f3 / f |=1.81, the focal length ratio of the fourth lens and the optical system |f4 / f|=0.48, the focal length ratio of the fifth lens and the optical system |f5 / f|=0.57, the focal length ratio of the sixth lens and the optical system |f6 / f|=0.88, the focal length ratio of the seventh lens and the optical system |f7 / f|=0.65, the focal length ratio of the first, secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com