A kind of preparation method of high-performance supercapacitor electrode

A supercapacitor, high-performance technology for hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, nanotechnology for materials and surface science, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

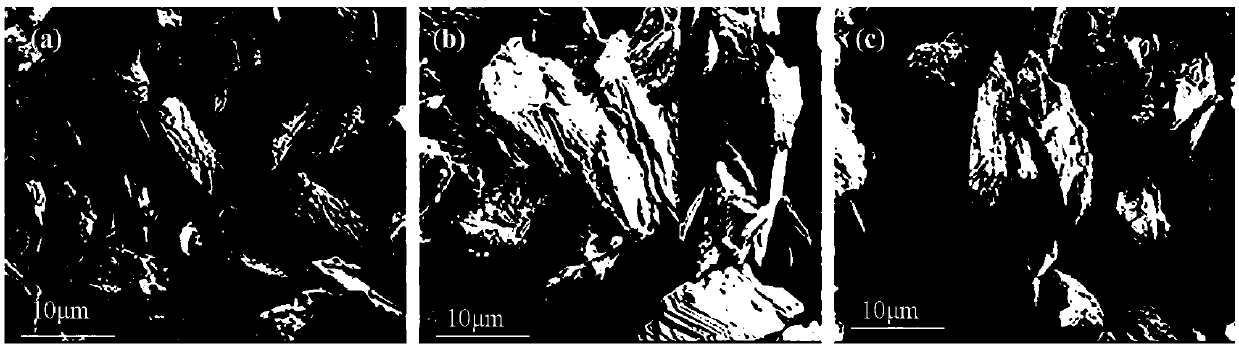

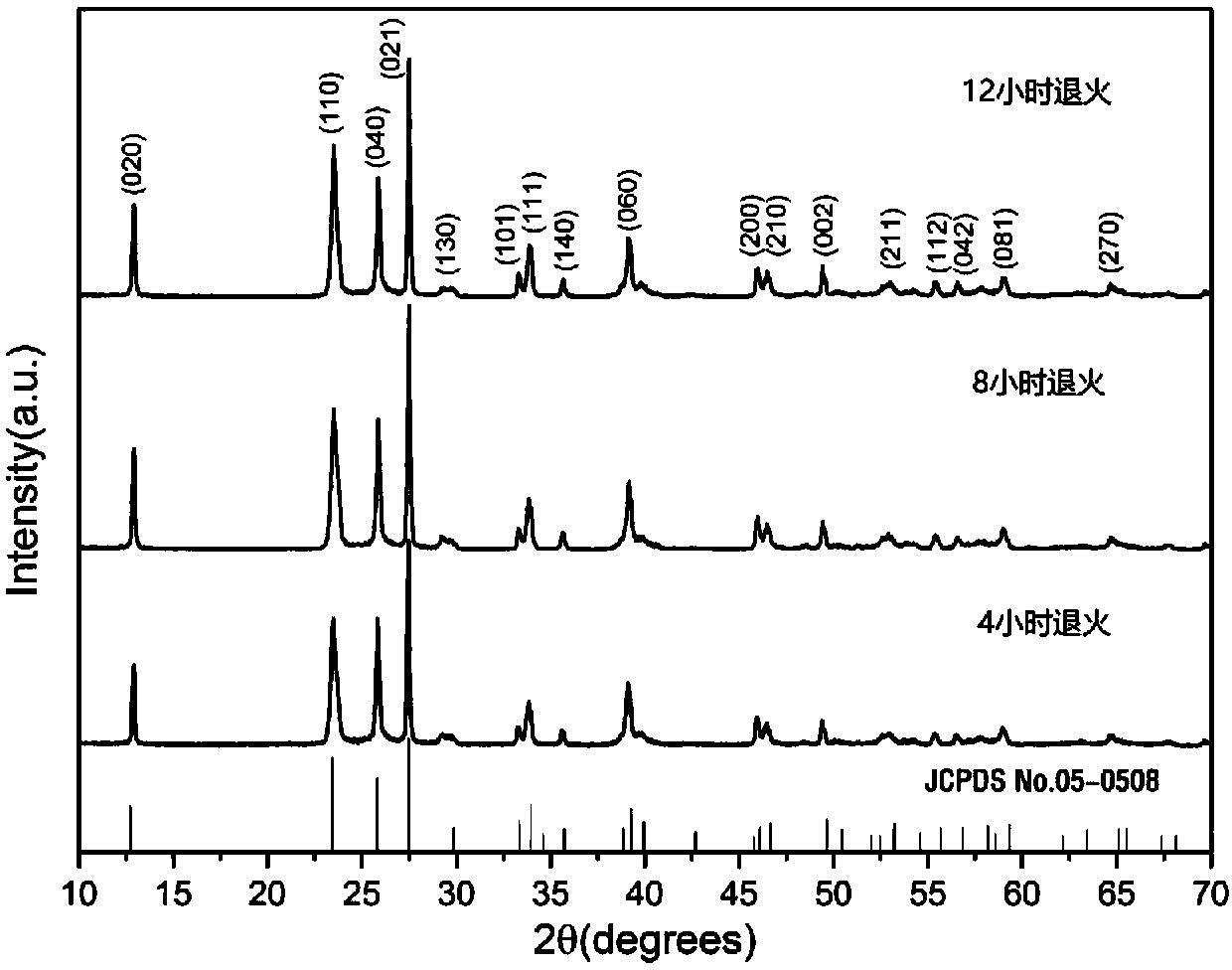

[0025] Example 1, α-MoO annealed for 4 hours 3 Preparation of Electrode Sheets

[0026] This example prepares α-MoO according to the following steps 3 Electrode sheet:

[0027] (1) h-MoO 3 Preparation of Nanomaterials

[0028] Will 0.005M (NH 4 ) 6 Mo 7 o 24 4H 2 O solution with 2M HNO 3 The solution was mixed evenly at a volume ratio of 8:1, and then placed in a constant temperature water bath at 85°C for 60 minutes; the resulting product was ultrasonically treated, filtered, and dried to obtain h-MoO 3 nanomaterials;

[0029] (2)α-MoO 3 Preparation of Nanolaminated Materials

[0030] h-MoO obtained in step (1) 3 Nanomaterials are placed in a muffle furnace, annealed at 500°C (the time required to rise from room temperature to 500°C is set to 100 minutes) for 4 hours, and then naturally cooled to room temperature to obtain α-MoO 3Nano laminated materials;

[0031] (3) Preparation of supercapacitor electrodes

[0032] The α-MoO obtained in step (2) 3 The nano-...

Embodiment 2

[0038] Example 2, α-MoO annealed for 4 hours 3 Preparation of Electrode Sheets

[0039] This example prepares α-MoO according to the following steps 3 Electrode sheet:

[0040] (1) h-MoO 3 Preparation of Nanomaterials

[0041] Will 0.005M (NH 4 ) 6 Mo 7 o 24 4H 2 O solution with 2M HNO 3 The solution was mixed evenly at a volume ratio of 8:1, and then placed in a constant temperature water bath at 85°C for 60 minutes; the resulting product was ultrasonically treated, filtered, and dried to obtain h-MoO 3 nanomaterials;

[0042] (2)α-MoO 3 Preparation of Nanolaminated Materials

[0043] h-MoO obtained in step (1) 3 Nanomaterials are placed in a muffle furnace, annealed at 500°C (the time required to rise from room temperature to 500°C is set to 100 minutes) for 8 hours, and then naturally cooled to room temperature to obtain α-MoO 3 Nano laminated materials;

[0044] (3) Preparation of supercapacitor electrodes

[0045] The α-MoO obtained in step (2) 3 The nano...

Embodiment 3

[0050] Example 3, α-MoO annealed for 12 hours 3 electrode sheet preparation

[0051] This example prepares α-MoO according to the following steps 3 Electrode sheet:

[0052] (1) h-MoO 3 Preparation of Nanomaterials

[0053] Will 0.005M (NH 4 ) 6 Mo 7 o 24 4H 2 O solution with 2M HNO 3 The solution was mixed evenly at a volume ratio of 8:1, and then placed in a constant temperature water bath at 85°C for 60 minutes; the resulting product was ultrasonically treated, filtered, and dried to obtain h-MoO 3 nanomaterials;

[0054] (2)α-MoO 3 Preparation of Nanolaminated Materials

[0055] With step (1) gained h-MoO 3 Nanomaterials are placed in a muffle furnace, annealed at 500°C (the time required to rise from room temperature to 500°C is set to 100 minutes) for 12 hours, and then naturally cooled to room temperature to obtain α-MoO 3 Nano laminated materials;

[0056] (3) Preparation of supercapacitor electrodes

[0057] The α-MoO obtained in step (2) 3 The nano-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com