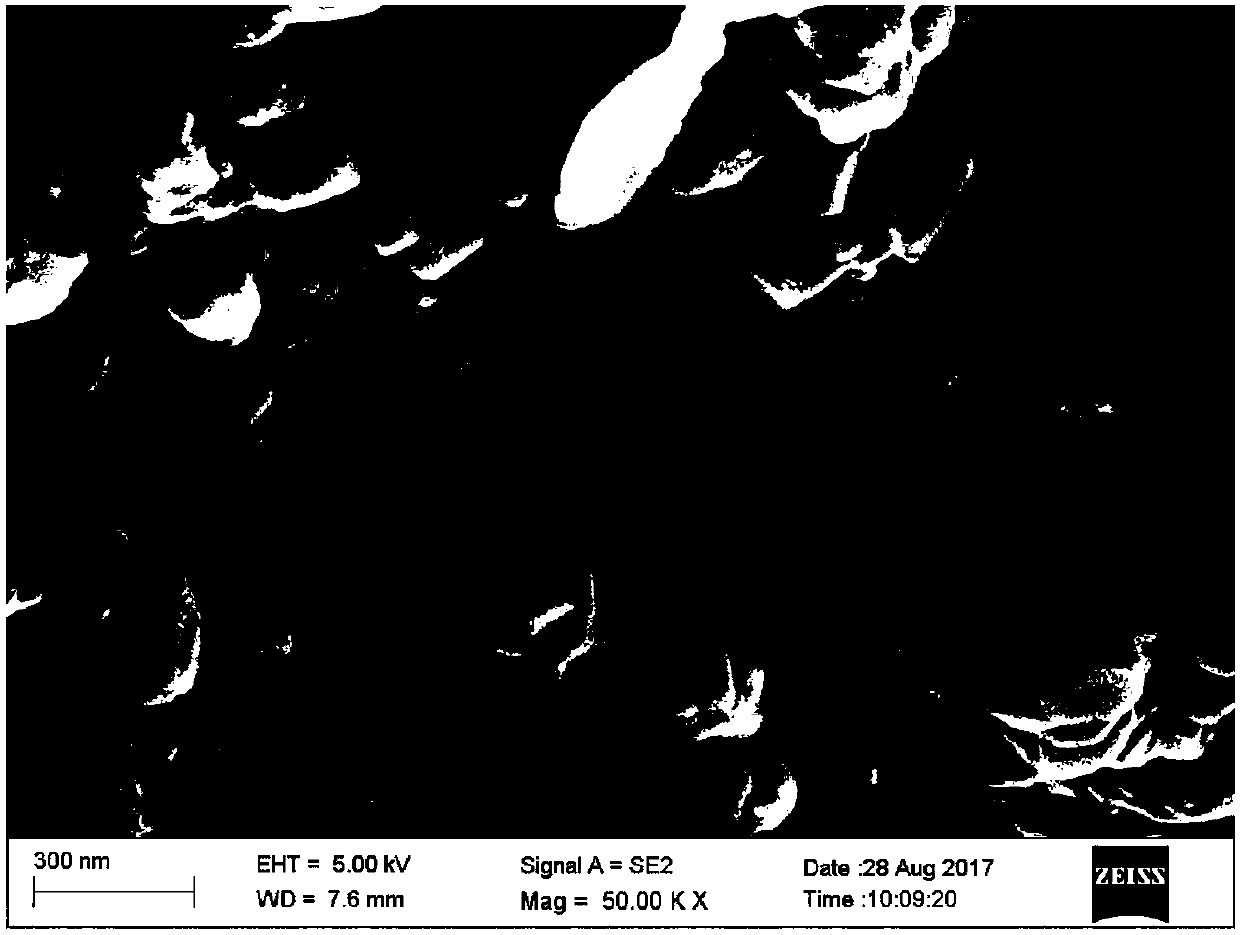

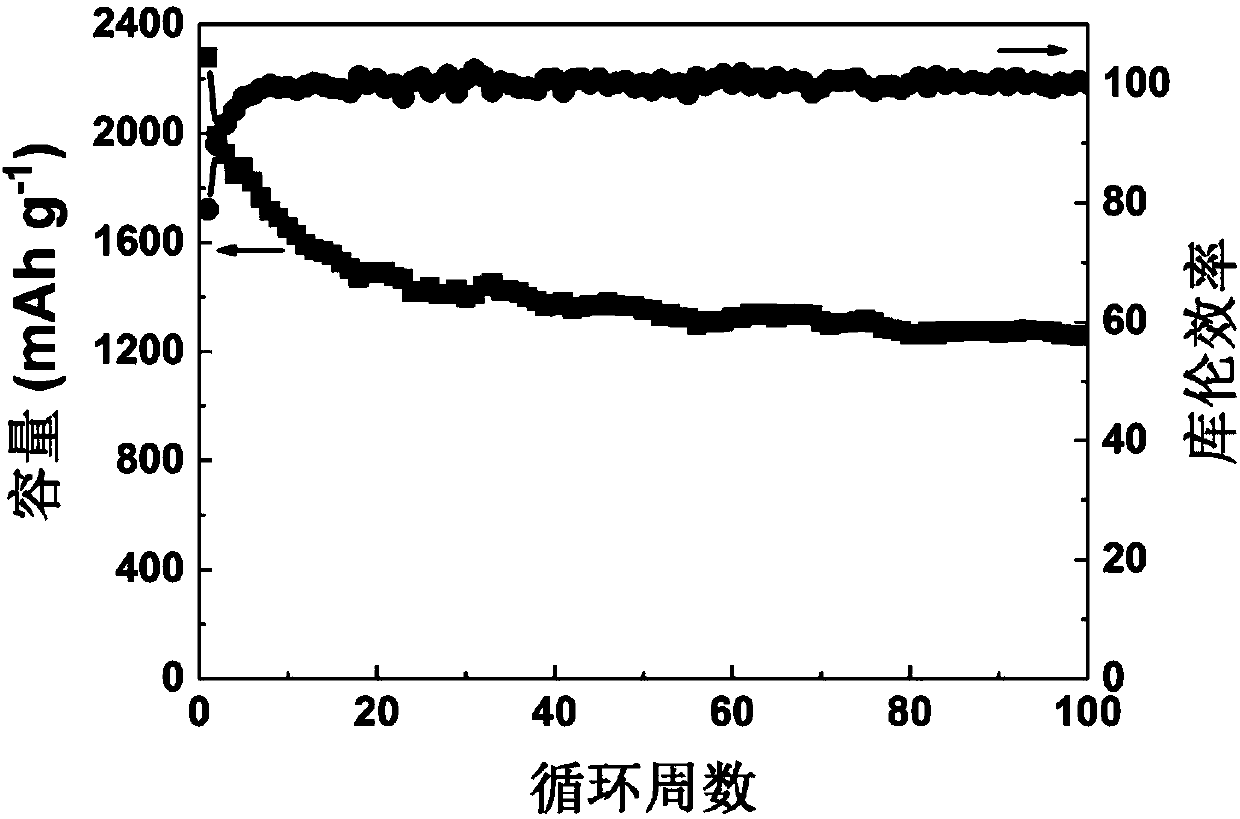

Preparation method of nanoporous silicon of negative electrode material of lithium battery

A nanoporous, negative electrode material technology, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of low specific energy, complex preparation method and high cost of porous silicon negative electrode materials, and achieve the realization of The effect of large-scale production, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 100g of nano-magnesium-silicon alloy, put it into a JVOQ433 vacuum heat treatment furnace, keep it at 1200°C for 30min under high vacuum, and keep the vacuum at -0.08MPa to obtain porous silicon.

Embodiment 2

[0036] Weigh 100g of nano-alumina-magnesium-silicon alloy, put it into a JVOQ433 type vacuum heat treatment furnace, keep warm at 1300°C for 20min under high vacuum, and keep the vacuum at -0.01MPa to obtain porous silicon.

Embodiment 3

[0038] Weigh 100g of nano-zinc-cadmium-silicon alloy, put it into a JVOQ433 type vacuum heat treatment furnace, keep warm at 1000°C for 50min under high vacuum, and keep the vacuum at -0.05MPa to obtain porous silicon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com