A processing method for rapid aluminum removal from pickled flame jellyfish

A processing method and technology of jellyfish, applied in the direction of food ultrasonic treatment, food heat treatment, food ingredients as taste improvers, etc., can solve the problems of bone toxicity and immunotoxicity, high residual aluminum in jellyfish, and long process time, so as to increase the throughput. Permeability and mass transfer rate, improving production efficiency and food safety, maintaining crispness and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

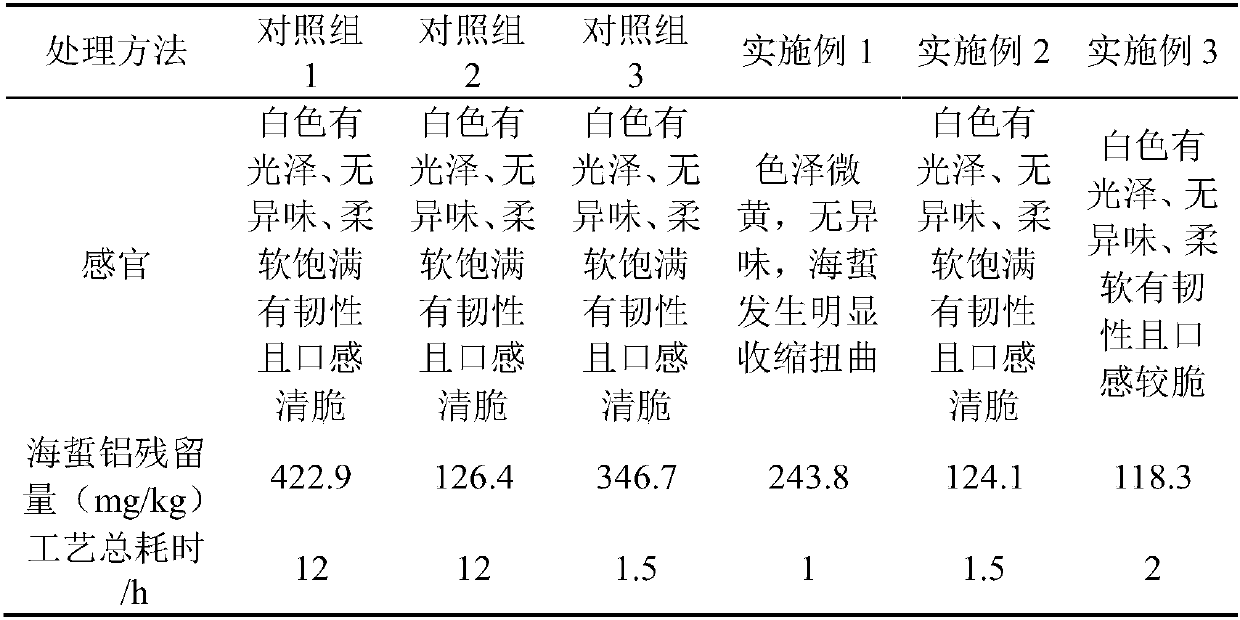

Embodiment 1

[0015] The technical scheme of the present invention is used to process the salted jellyfish skins purchased from the market with the traditional three-aluminum process, and determine the residual amount of aluminum therein.

[0016] A processing method for fast dealumination of salted jellyfish, the steps of which include cleaning, ultrasonic-assisted immersion in a mixed solution of acetic acid and calcium propionate and hot water blanching, and the specific steps are as follows:

[0017] 1) Cleaning: Wash the salted jellyfish with water to remove impurities and cut into pieces.

[0018] 2) Ultrasonic-assisted immersion in a mixed solution of acetic acid and calcium propionate: soak the above-mentioned salted jellyfish in a mixed solution of 0.6% acetic acid and calcium propionate at a material-to-liquid ratio of 1:7, and place it in an ultrasonic device for ultrasonic assistance. For dealumination, the ultrasonic power is 200W, the ultrasonic frequency is 25kHZ, the ultraso...

Embodiment 2

[0021] The technical scheme of the present invention is used to process the salted jellyfish skins purchased from the market with the traditional three-aluminum process, and determine the residual amount of aluminum therein.

[0022] A processing method for fast dealumination of salted jellyfish, the steps of which include cleaning, ultrasonic-assisted immersion in a mixed solution of acetic acid and calcium propionate and hot water blanching, and the specific steps are as follows:

[0023] 1) Cleaning: Wash the salted jellyfish with water to remove impurities and cut into pieces.

[0024] 2) Ultrasonic-assisted immersion in a mixed solution of acetic acid and calcium propionate: soak the above-mentioned salted jellyfish in a mixed solution of 0.7% acetic acid and calcium propionate at a material-to-liquid ratio of 1:7, and place it in an ultrasonic device for ultrasonic assistance. For dealumination, the ultrasonic power is 300W, the ultrasonic frequency is 28kHZ, the ultraso...

Embodiment 3

[0027] The technical scheme of the present invention is used to process the salted jellyfish skins purchased from the market with the traditional three-aluminum process, and determine the residual amount of aluminum therein.

[0028] A processing method for fast dealumination of salted jellyfish, the steps of which include cleaning, ultrasonic-assisted immersion in a mixed solution of acetic acid and calcium propionate and hot water blanching, and the specific steps are as follows:

[0029] 1) Cleaning: Wash the salted jellyfish with water to remove impurities and cut into pieces.

[0030] 2) Ultrasonic-assisted immersion in a mixed solution of acetic acid and calcium propionate: the above-mentioned salted jellyfish is soaked in a mixed solution of 0.8% acetic acid and calcium propionate at a material-to-liquid ratio of 1:7, and placed in an ultrasonic device for ultrasonic assistance. For dealumination, the ultrasonic power is 400W, the ultrasonic frequency is 40kHZ, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com