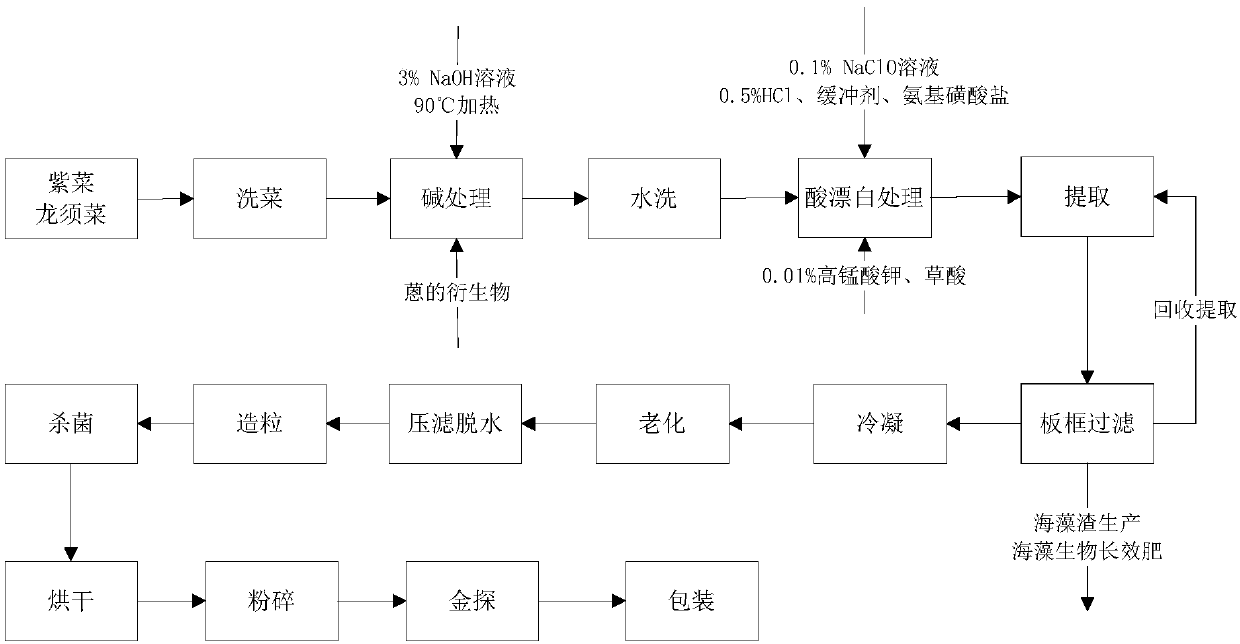

Method for extracting agar from nori and asparagus

A technology of asparagus and agar, which is applied in the field of extracting agar from laver and asparagus, which can solve the problems of excessive chemical residues and cumbersome processes, achieve broad export prospects, improve gel strength, and reduce chemical residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The first step, washing vegetables: 1.5 tons of seaweed or asparagus, prepare 15 tons of NaOH solution with a percentage content of 7%, and heat the sodium hydroxide solution to 80 ° C, pour the heated sodium hydroxide solution into the Soak in a vegetable washing tank containing 1.5 tons of vegetables for 2-4 hours at a constant temperature;

[0075] The second step, alkali treatment: after soaking, pump the NaOH solution into the heating tank, add water to spray the vegetable body, make the total amount of NaOH solution about 14 tons, and then add an appropriate amount of 30% liquid alkali to increase the alkali content of the lye. 3-10%, at the same time add 0.05% anthracene derivatives by weight of algae to increase the yield of agar;

[0076] The third step, water washing: soak in tap water for 2 hours for the first wash and discharge, soak for 4 hours in tap water for the second wash and discharge, soak in tap water for 6 hours in the third, fourth, and fifth wash...

Embodiment 2

[0100] The difference from Example 1 is that in the first step, 15 tons of 11% NaOH solution is prepared and heated to 90°C.

Embodiment 3

[0102] The difference from Example 1 is that the fourth step of acid bleaching treatment: after washing, add hydrochloric acid and sulfamic acid salt, add an available chlorine content of 0.1% sodium hypochlorite solution, adjust the pH value to 4, and perform a bleaching. After 30 minutes, add 0.01% potassium permanganate and oxalic acid, adjust the pH value to 5, and perform secondary bleaching. After 20-30 minutes, wash again until neutral;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whiteness | aaaaa | aaaaa |

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com