Preparation method and application of flexible stretchable sensing array based on bidirectional pre-stretching elastic substrate and aligned carbon nanotubes

A carbon nanotube and tensile sensing technology, which is applied in the direction of using electric/magnetic devices to transmit sensing components, can solve the problems of single function of flexible sensors, and achieve the effect of simple and convenient preparation method and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention is a method for preparing a flexible and stretchable sensor array based on bidirectionally pre-stretched elastic substrates and aligned carbon nanotubes, which specifically includes the following steps:

[0026] Step one, the preparation of the elastomer substrate.

[0027] In one example, a purchased common commercial product thermoplastic elastomer SEBS (saturated styrene-butadiene-styrene block copolymer) was rinsed with tap water, followed by ultrasonic cleaning with alcohol and deionized water for 10-30 min , put it into a blast drying oven at 40-50°C for 5-10 minutes, cut the washed elastic body into a square, and stretch it bidirectionally with a clamp as a bidirectionally pre-stretched elastic body SEBS.

[0028] Step 2, preparation of the mixed solution of the medium layer.

[0029] In one embodiment, 2.18 g of the cleaned thermoplastic elastomer SEBS was dissolved in 50 mL of cyclohexane, and the dissolution was accelerated by ultrasonic...

Embodiment 1

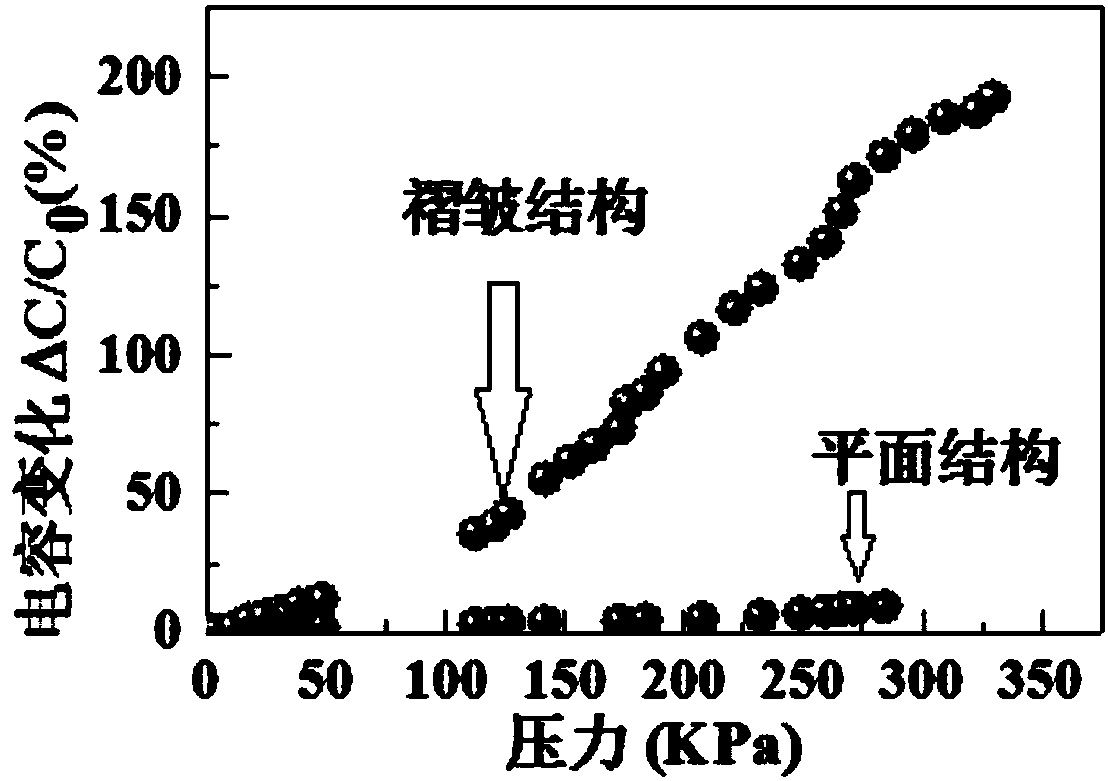

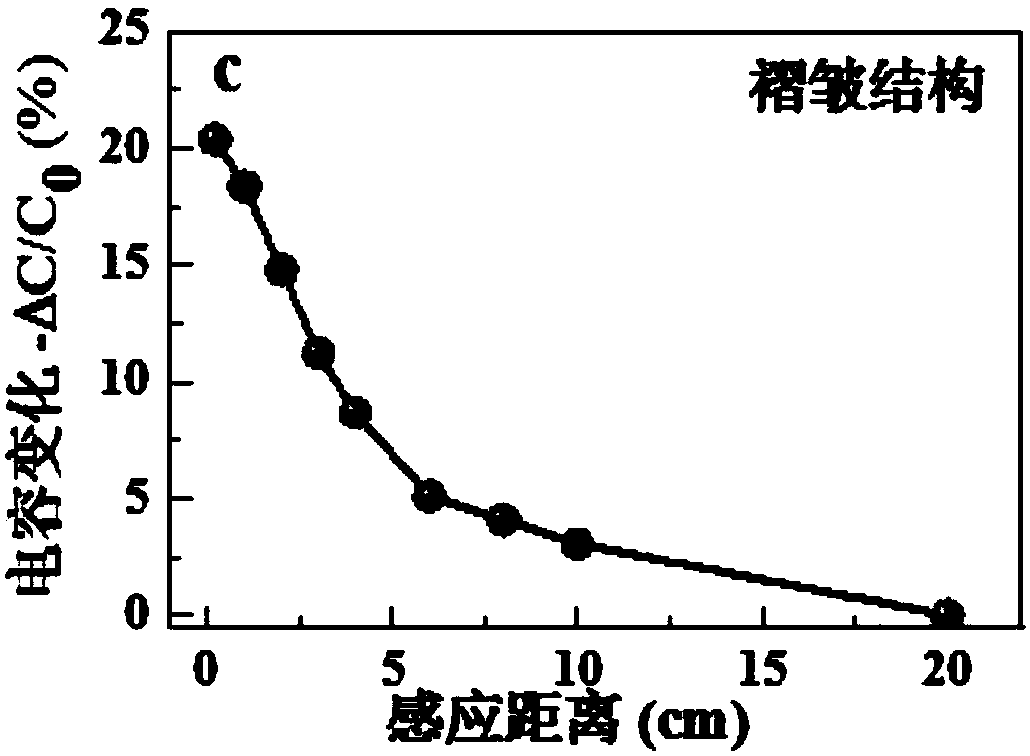

[0039] Fabrication of flexible and stretchable sensor arrays based on bidirectionally pre-stretched elastic substrates and aligned carbon nanotubes.

[0040] Step 1: Preparation of elastomeric substrate: The purchased common commercial product thermoplastic elastomer SEBS (saturated styrene-butadiene-styrene block copolymer) was rinsed with tap water, followed by ultrasonic cleaning with alcohol and deionized water for 30 min , put it into a blast drying oven at 50°C for 10 minutes, and cut the cleaned elastomer into 5×5cm 2 The square shape is biaxially stretched with a jig as the base material.

[0041] Step 2: Preparation of the mixed solution of the medium layer: Dissolve 2.18 g of the cleaned thermoplastic elastomer SEBS in 50 mL of cyclohexane, and accelerate the dissolution by ultrasonication for 60 min, and set aside.

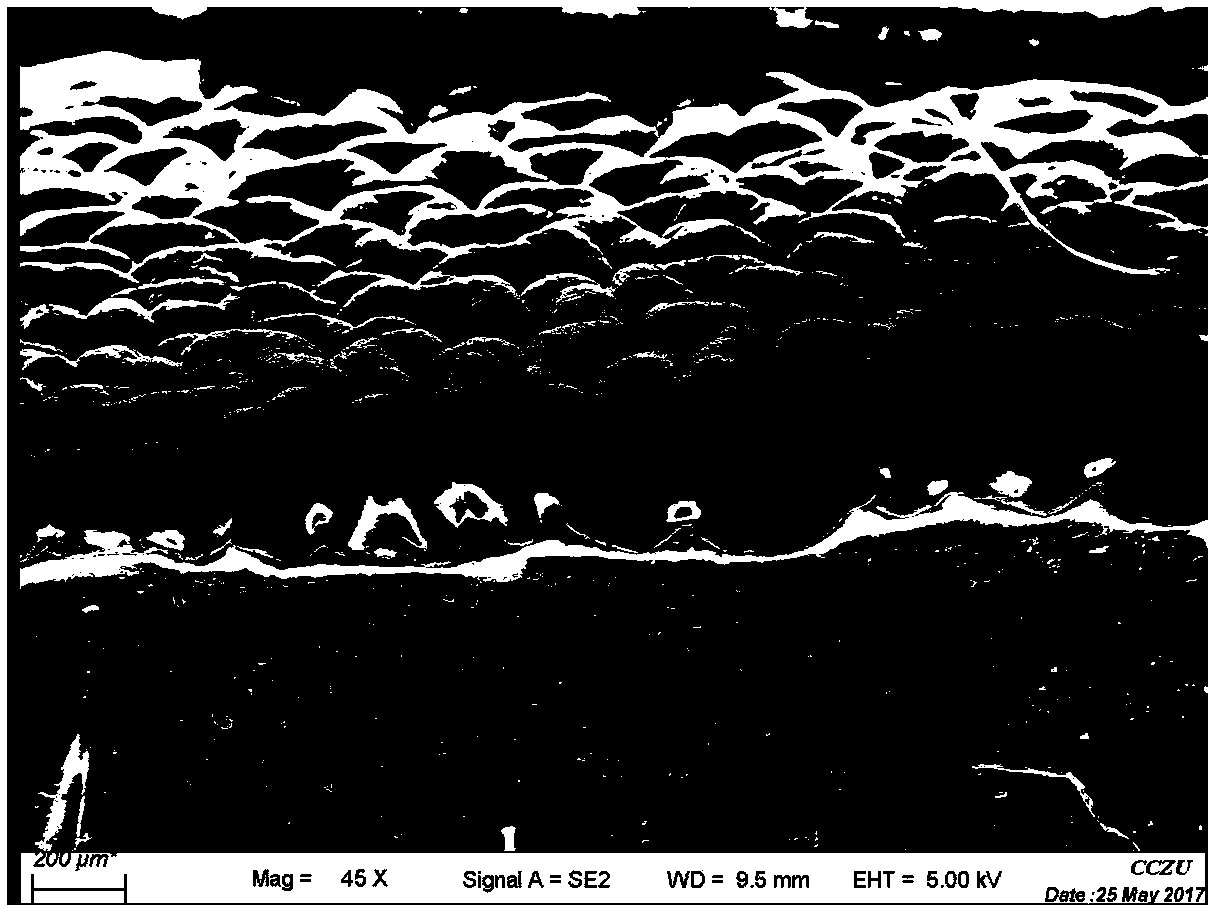

[0042] Step 3: Preparation of the aligned carbon nanotube film: directly extract the carbon nanotube film from the multi-walled carbon nanotube array ...

Embodiment 2

[0045] Fabrication of flexible and stretchable sensor arrays based on bidirectionally pre-stretched elastic substrates and aligned carbon nanotubes.

[0046] Step 1: Preparation of the elastomeric substrate: The purchased common commercial product thermoplastic elastomer SEBS (saturated styrene-butadiene-styrene block copolymer) was rinsed with tap water, followed by ultrasonic cleaning with alcohol and deionized water for 10 min , put it into a blast drying oven at 40°C for 5 minutes, and cut the washed elastomer into 5×5cm 2 The square shape is biaxially stretched with a jig as the base material.

[0047] Step 2: Preparation of the mixed solution of the medium layer: Dissolve 2.18 g of the cleaned thermoplastic elastomer SEBS in 50 mL of cyclohexane, and accelerate the dissolution by ultrasonication for 60 min, and set aside.

[0048] Step 3: Preparation of the aligned carbon nanotube film: directly extract the carbon nanotube film from the multi-walled carbon nanotube arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com