Plate grid corrosion test method at high temperature and apparatus therefor

A technology for corrosion testing and high-temperature environments, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as long time consumption, high test cost, product scrap loss, etc., to achieve accurate closure and reduce testing cost, the effect of simplifying the testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

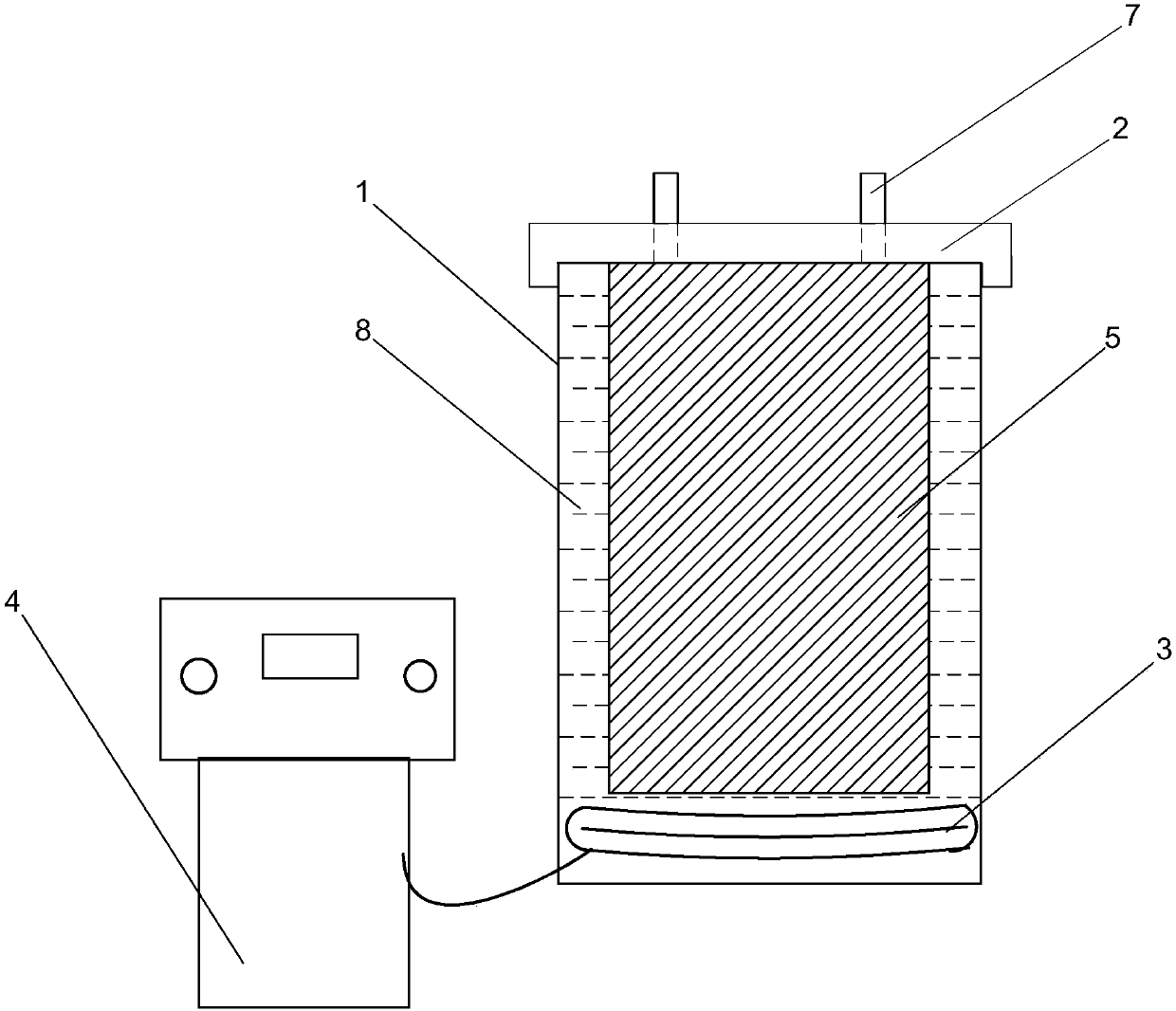

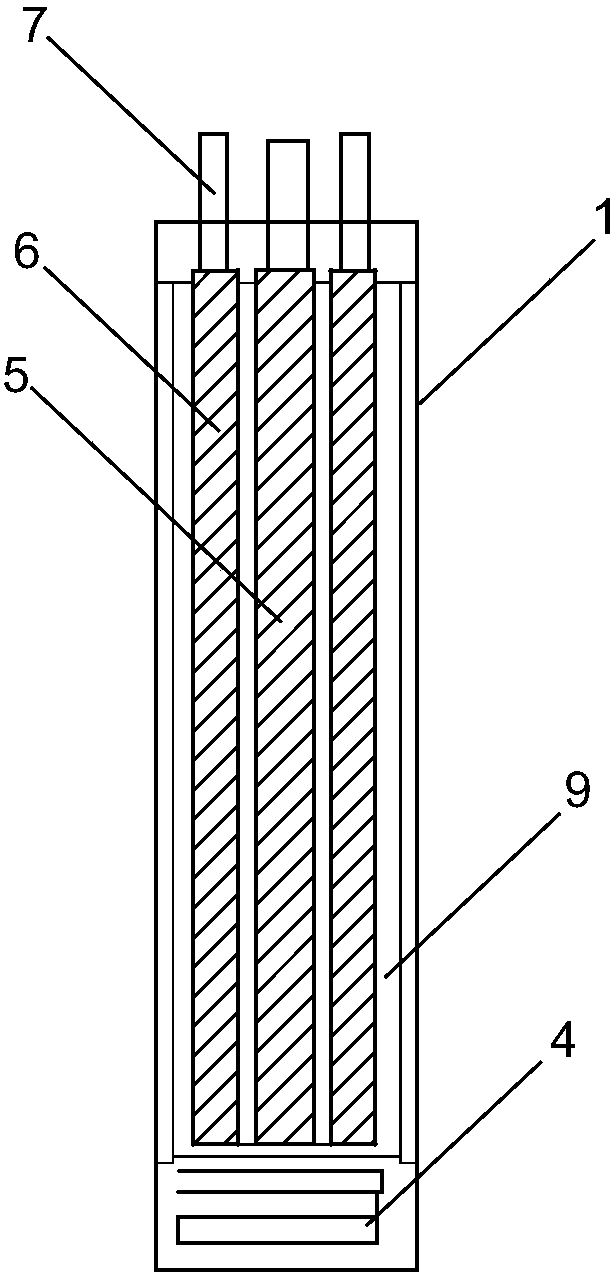

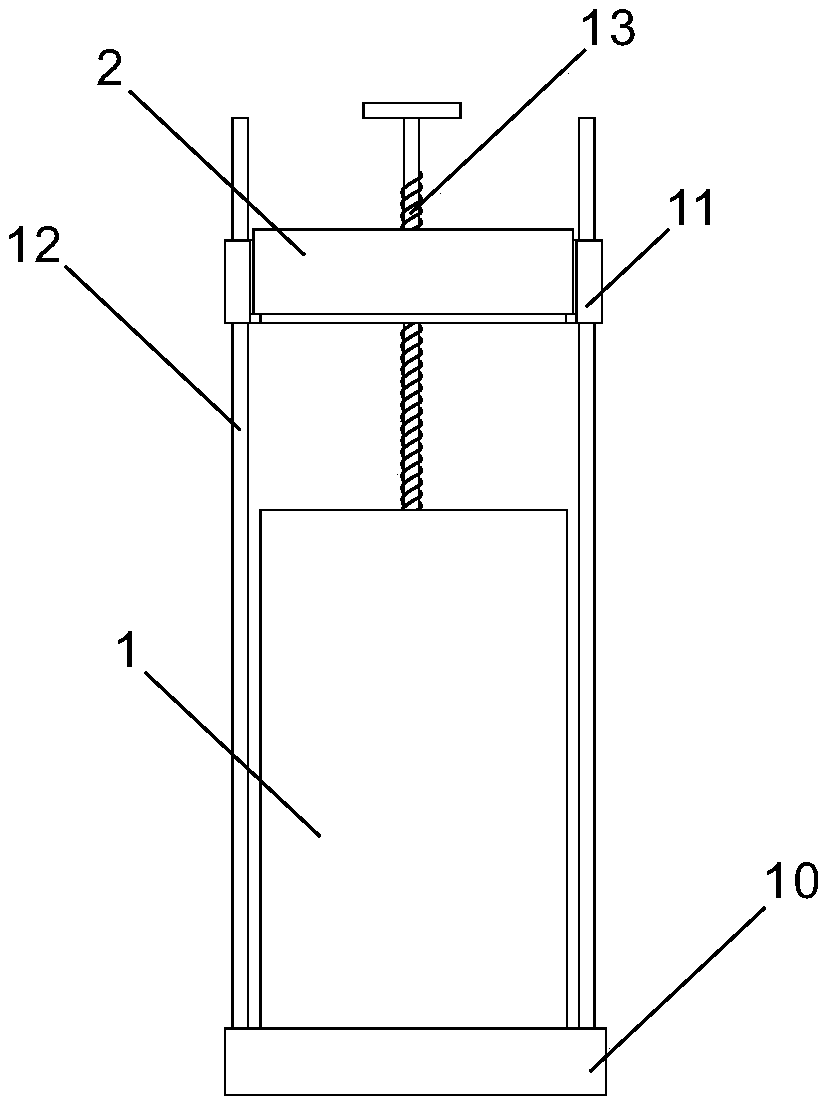

[0033] Such as figure 1 , figure 2 As shown, a high-temperature environment grid corrosion test method includes the following steps:

[0034] A. Make a special high-temperature environment grid corrosion test device;

[0035] B. Select the positive grid and negative grid sample pieces made according to their respective standards, cut out a grid sample piece on each grid, and press it straight. The length of the grid sample piece is 198mm, and the width is 198mm. 98mm, and each grid sample piece retains a tab on the grid;

[0036] C. Use a balance to weigh the grid sample piece in turn, record the weight of the grid sample piece before the corrosion test, and the weighing result is accurate to four decimal places;

[0037] D. Cover the positive grid sample piece 5 with a single piece of AGM separator of the corresponding specification, and then use the negative grid sample piece 6 to paste and press on both sides of the positive grid sample piece 5 coated by AGM to form...

Embodiment 2

[0046] The length of the grid sample piece is 200mm and the width is 100mm. The density of the colloidal electrolyte used is 1.24g / cm 3 , the electrolyte temperature was 58°C, and the battery was charged with a constant current of 1.8A for 169h. The components of the corrosion film treatment solvent are 3.5% sodium hydroxide, 14% glucose, and the rest are water. There are three pairs of clamping block embedding grooves and reaction tank cover clamping blocks respectively. All the other are with embodiment 1.

Embodiment 3

[0048] The length of the grid sample piece is 202mm, and the width is 102mm. The density of the colloidal electrolyte used is 1.26g / cm 3 , the temperature of the electrolyte is 62°C, and the battery is charged with a constant current of 2.0A for 168h. The components of the corrosion film treatment solvent are 4% sodium hydroxide, 16% glucose, and the rest are water. There are four pairs of clamping block embedding grooves and reaction tank cover clamping blocks respectively. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com