Solar energy cell silicon chip etching water film solution and application thereof

A solar cell and water film technology, applied in the field of solar cells, can solve the problems of destroying the PN junction, aggravating the corrosion damage of the PN junction, and being unable to protect the PN junction very well, so as to achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

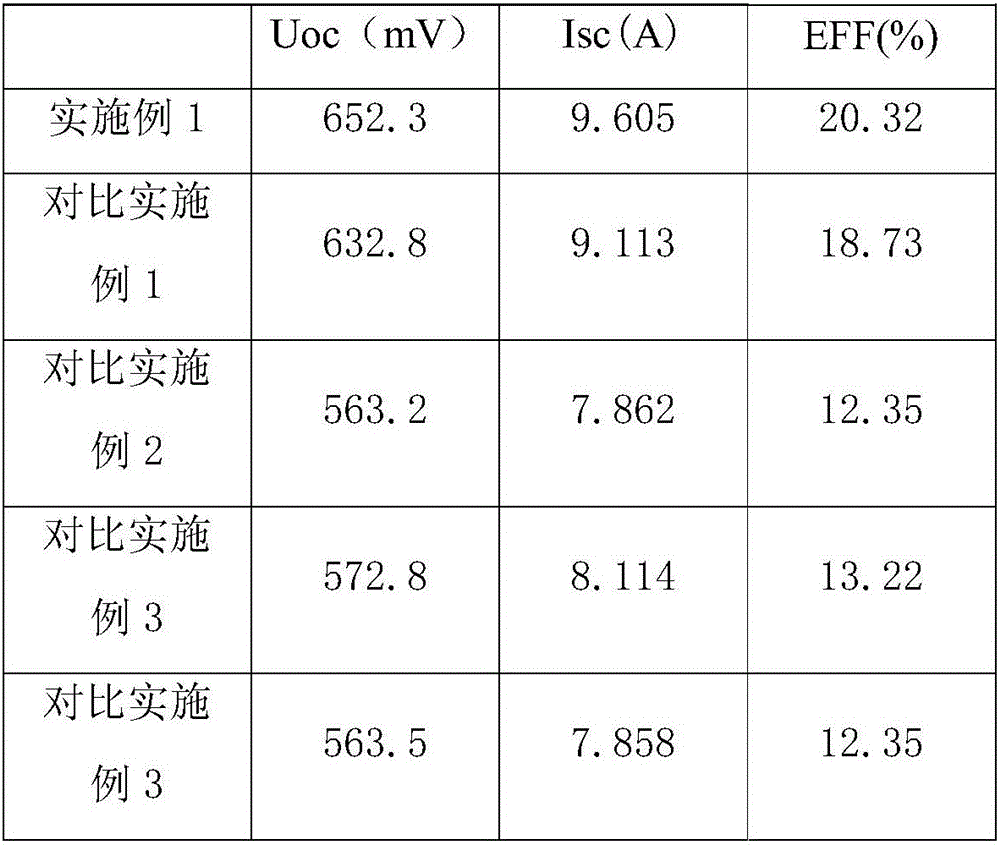

Examples

Embodiment 1

[0018] Preparation glucose content is 2.0g / L, bisfluorosulfonimide sodium content is the aqueous film solution of 0.25mol / L,

[0019] (1) Through the water film spray covering technology, the above-mentioned water film is sprayed on the diffusion surface formed by diffusion on the surface of the silicon wafer to form a flat water film protective layer, and the water film protective layer continues to exist until the silicon wafer Complete the etching step,

[0020] (2) Put the silicon wafer processed in step (1) into the etching tank, and the etching solution is commonly used HF / HNO 3 / H 2 SO 4 Mixed acid, in the etching tank, the silicon wafer is etched by floating on the etching solution,

[0021] The etch amount on the backside of the silicon wafer is 8 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com