A kind of anti-flash rust waterborne acrylic iron red antirust primer and preparation method thereof

A technology of acrylic iron red and anti-rust primer, applied in anti-corrosion coatings, biocide-containing paints, anti-fouling/underwater coatings, etc., can solve the cracked metal corrosion of paint film, the expansion of corrosion of metal workpieces, and the flash rust of metal workpieces and other problems, to achieve the effect of inhibiting corrosion, inhibiting redissolution, and excellent anti-flash rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

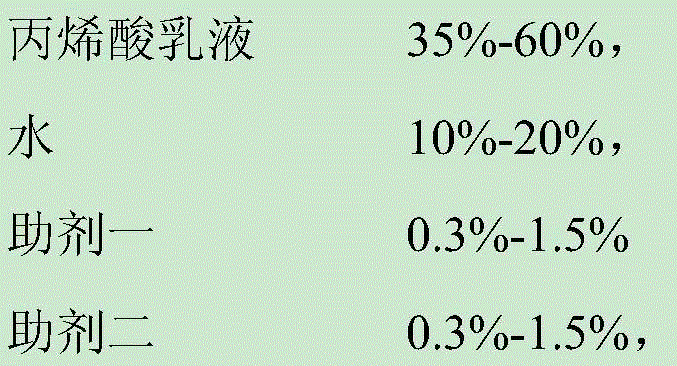

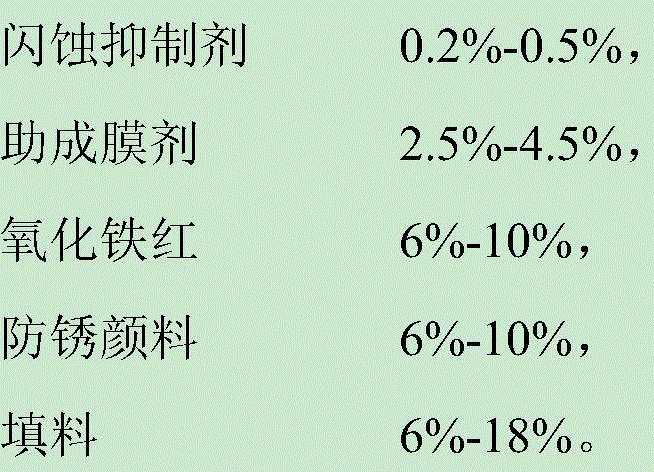

[0027] A kind of anti-flash rust waterborne acrylic iron red antirust primer, wherein each component and mass percentage are as follows:

[0028] Acrylic emulsion (DSMXK-86) 60%, water 11%, additive 1 0.7% (including wetting and dispersing agent 0.35%, bactericide 0.2%, defoamer 0.15%), additive 2 0.8% (including defoamer 0.1%, thickener 0.17%, substrate wetting agent 0.15%, leveling agent 0.3%, PH regulator 0.08%), flash corrosion inhibitor 0.5%, film-forming agent 4.5% (dipropylene glycol monoethyl ether 2.25%, Dodecyl alcohol ester 2.25%), iron oxide red 6.7%, anti-rust pigment ( ZCP PLUS , a zinc silicate orthophosphate hydrate containing calcium, strontium, aluminum) 8%, filler 7.8%;

[0029] Among them, the filler formula is: precipitated barium sulfate 30%, silicon micropowder 15%, talc powder 20%, gray mica 20%, kaolin 10%, hydrated magnesium aluminum silicate 2%, montmorillonite 3%.

[0030] The preparation method of above-mentioned antirust primer is as follows: ...

Embodiment 2

[0035] A kind of anti-flash rust waterborne acrylic iron red antirust primer, wherein each component and mass percentage are as follows:

[0036] Acrylic emulsion (DSMXK-86) 55%, water 12%, additive 1 0.8% (including wetting and dispersing agent 0.45%, bactericide 0.2%, defoamer 0.15%), additive 2 0.8% (including defoamer 0.1%, thickener 0.17%, substrate wetting agent 0.15%, leveling agent 0.3%, PH regulator 0.08%), flash corrosion inhibitor 0.3%, film-forming agent 4.5% (dipropylene glycol monoethyl ether 2.25%, Dodecyl alcohol ester 2.25%), iron oxide red 7.6%, anti-rust pigment ( ZCP PLUS ) 8%, filler 11%;

[0037] Among them, the filler formula is: precipitated barium sulfate 30%, silica powder 7%, talc powder 25%, gray mica 25%, kaolin 10%, montmorillonite 3%.

[0038] The preparation method of above-mentioned antirust primer is as follows:

[0039] (1) Preparation of flash corrosion inhibitor: Mix 40 parts of sebacic acid and 30 parts of boric acid, heat to 65°C and...

Embodiment 3

[0043] A kind of anti-flash rust waterborne acrylic iron red antirust primer, wherein each component and mass percentage are as follows:

[0044] Acrylic emulsion (DSMXK-86) 45%, water 16%, additive 1.0% (including wetting and dispersing agent 0.65%, bactericide 0.2%, defoamer 0.15%), additive 2 0.8% (including defoamer 0.2%, thickener 0.32%, substrate wetting agent 0.20%, PH regulator 0.08%), flash corrosion inhibitor 0.4%, film-forming agent 3.5% (dipropylene glycol monoethyl ether 1.75%, lauryl alcohol ester 1.75 %), iron oxide red 9.3%, anti-rust pigment 8%, filler 16%;

[0045] The filler formula is: precipitated barium sulfate 30%, silica powder 30%, gray mica 20%, kaolin 18%, montmorillonite 2%.

[0046] The preparation method of above-mentioned antirust primer is as follows:

[0047] (1) Preparation of flash corrosion inhibitor: Mix 20 parts of tannic acid and 15 parts of boric acid, heat to 80°C, stir, melt and mix for 5 minutes, then add 15 parts of thiourea, 10 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com