Alkaline zinc-iron plating bath

A zinc-iron, alkaline technology, applied in the field of alkaline zinc-iron plating bath, can solve problems such as low current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

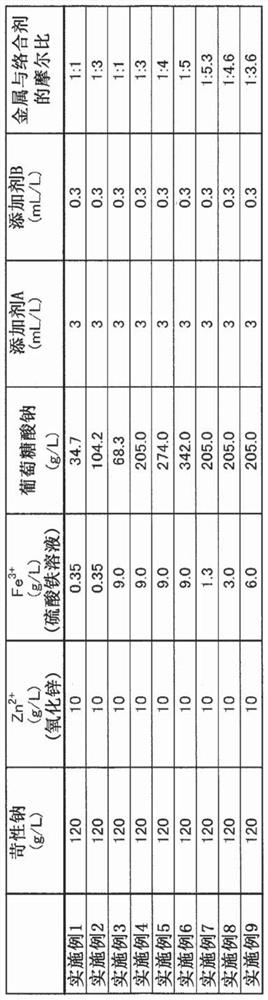

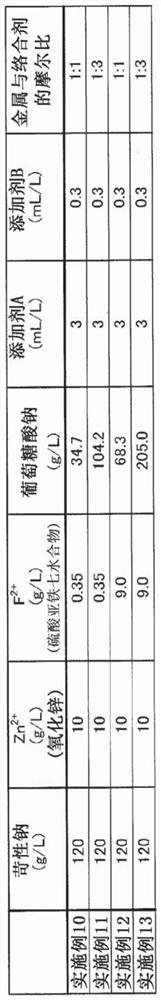

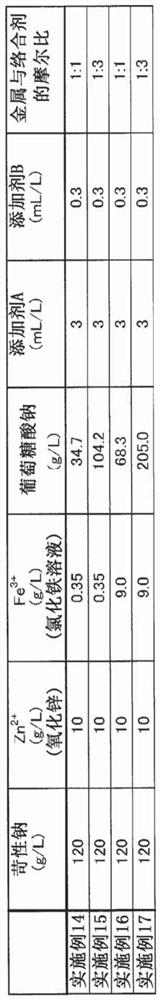

[0159] Hereinafter, the present invention will be described in more detail with reference to Examples. However, this invention is not limited to this Example, According to the knowledge of those skilled in the art, it can implement in various forms which made various changes and improvements.

[0160] use Figure 1 to Figure 15 Alkaline zinc-iron plating baths of Examples 1 to 53 and Comparative Examples 1 to 14 were constructed with the raw materials in the indicated ratios. In addition, the details of each raw material are as follows.

[0161] Caustic soda (NaOH): Product made in Tokuyama Co., Ltd.

[0162] Zinc oxide (ZnO): manufactured by Hakusui Tech Co., Ltd.

[0163] Ferric sulfate solution (Fe 2 (SO 4 ) 3 ): manufactured by Jujo Institute of Synthetic Chemistry Co., Ltd.

[0164] Ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O: manufactured by Fujifilm Wako Pure Chemical Industries, Ltd.

[0165] Ferric chloride solution (FeCl 3 ): Product made in Hiiei Store C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com