A kind of protection method of metal electrode when soi MEMS sacrificial layer corrodes

A metal electrode and sacrificial layer technology, applied in the direction of metal material coating process, coating, and process for producing decorative surface effects, etc., can solve the problem of short extension time, achieve good integrity, increase flexibility, and extend The effect of corrosion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly understand the technical solution of the present invention, its detailed structure will be presented in the following description. Obviously, the implementation of the embodiments of the invention is not limited to specific details familiar to those skilled in the art. The preferred embodiments of the present invention are described in detail below, and there may be other implementations besides those described in detail.

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

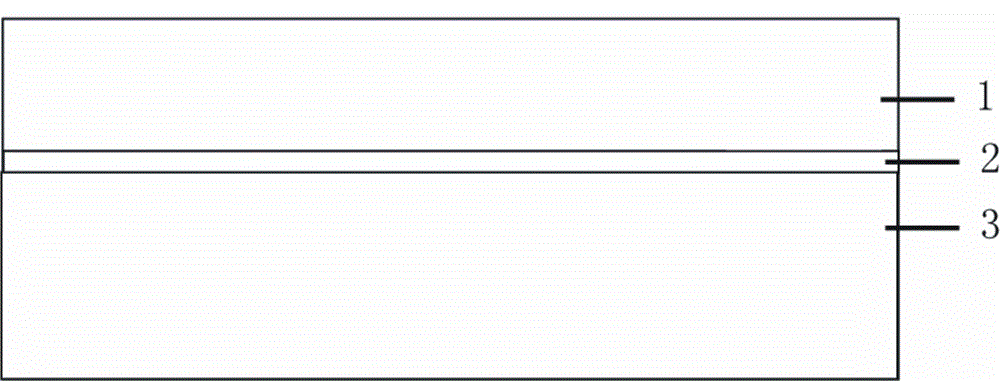

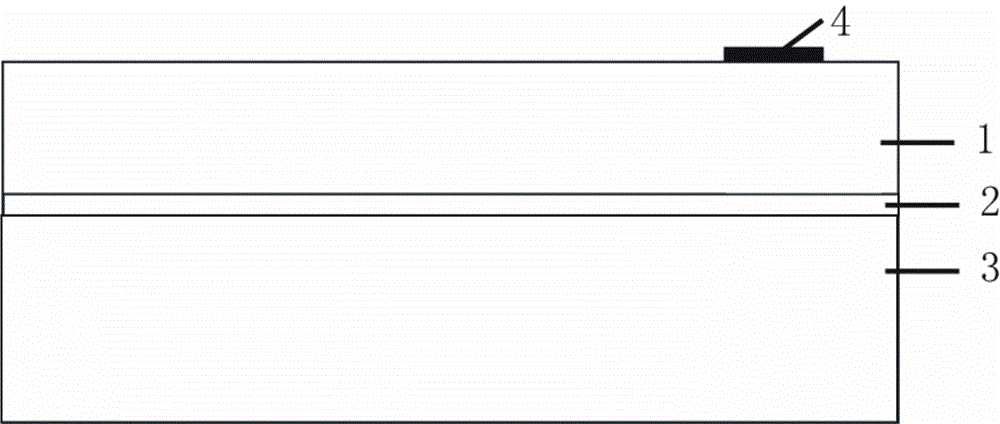

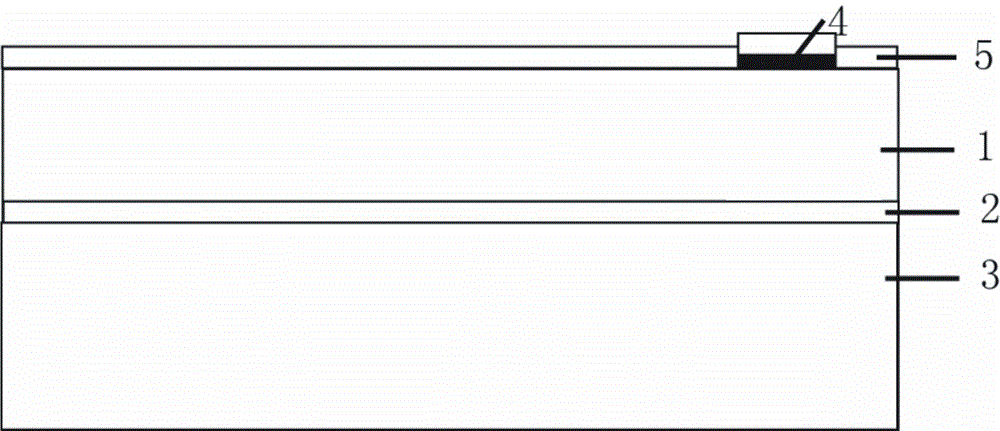

[0027] refer to figure 1 , the material used in this embodiment is an SOI silicon wafer, and the SOI includes a structural layer 1, a substrate layer 3, and an insulating layer 2 between the structural layer 1 and the substrate layer 3, and the thickness of the structural layer 1 is 80 μm. N-type silicon, resistivity 0.01~0.1Ω / cm, crystal orientation; insulating layer 2 thickness 5 μm; substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com