PFA photoresist regeneration stripping solution and preparation method and application thereof

A technology of stripping liquid and photoresist, which is applied in the field of electronic chemicals, can solve the problems of high content of metal impurity particles, constant stripping ability, and short copper corrosion time, so as to achieve simple components and prolong the corrosion time , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

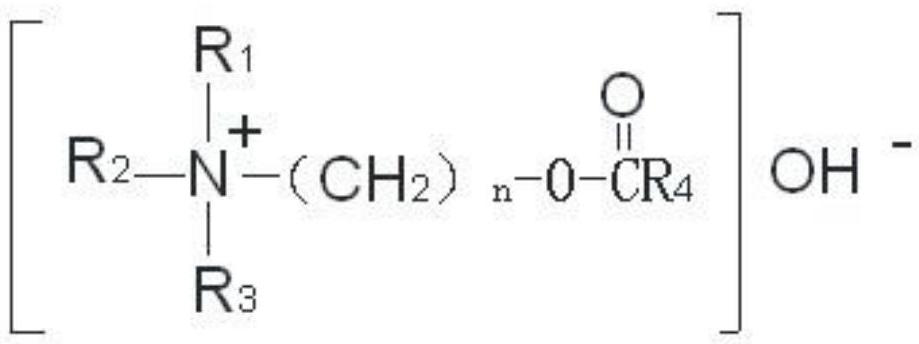

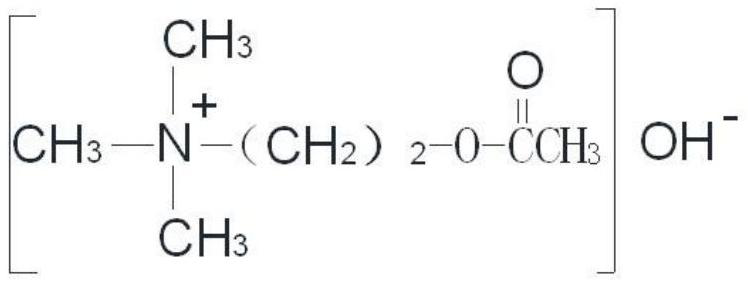

[0040] PFA photoresist regeneration stripping solution is composed of the following components by weight:

[0041]

[0042] 7 servings, R 1 —O—R 2 —NH—R 3 5 parts, 75 parts of ethylene glycol, 0.5 part of nonionic surfactant, 0.1 part of corrosion inhibitor, 12.4 parts of deionized water.

[0043] The ester-based hydroxide in this embodiment is firstly generated methyl ethanolamine ethyl ester salt from methyl ethanolamine, acetic acid and methyl chloride, and then the corresponding methyl ethanolamine is prepared by the reaction of methyl ethanolamine ethyl ester salt and potassium hydroxide Ethyl ester hydroxide; non-ionic surfactant is silicone defoamer; corrosion inhibitor is phenyltriazole.

Embodiment 2

[0045] PFA photoresist regeneration stripping solution is composed of the following components by weight:

[0046]

[0047] 20 servings, R 1 —O—R 2 —NH—R 3 12 parts, 60 parts of propylene glycol, 0.5 parts of corrosion inhibitor, 2.0 parts of non-ionic surfactant, 8.5 parts of deionized water.

[0048] In this embodiment, the ester hydroxide is methyl ethyl alcohol amine methyl hydroxide; the nonionic surfactant is sucrose ester; and the corrosion inhibitor is iminodiacetic acid.

Embodiment 3

[0050] PFA photoresist regeneration stripping solution is composed of the following components by weight:

[0051]

[0052] 15 servings, R 1 —O—R 2 —NH—R 3 10 parts, 70 parts of ethylene glycol, 0.5 parts of corrosion inhibitor, 2.0 parts of non-ionic surfactant, and 2.5 parts of deionized water.

[0053] In this embodiment, the ester hydroxide is methyl alcoholamine ethyl ester hydroxide; the nonionic surfactant is sucrose ester; the corrosion inhibitor is a 1:1 mixture of iminodiacetic acid and TTA, R 1 —O—R 2 —NH—R 3 for ethanolamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com