Surface enhanced Raman substrate and preparation method thereof

A surface-enhanced Raman and substrate technology, applied in Raman scattering, measuring devices, instruments, etc., can solve the problems of poor reproducibility of Raman scattering signals, and achieve the effect of regular arrangement, good reproducibility and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

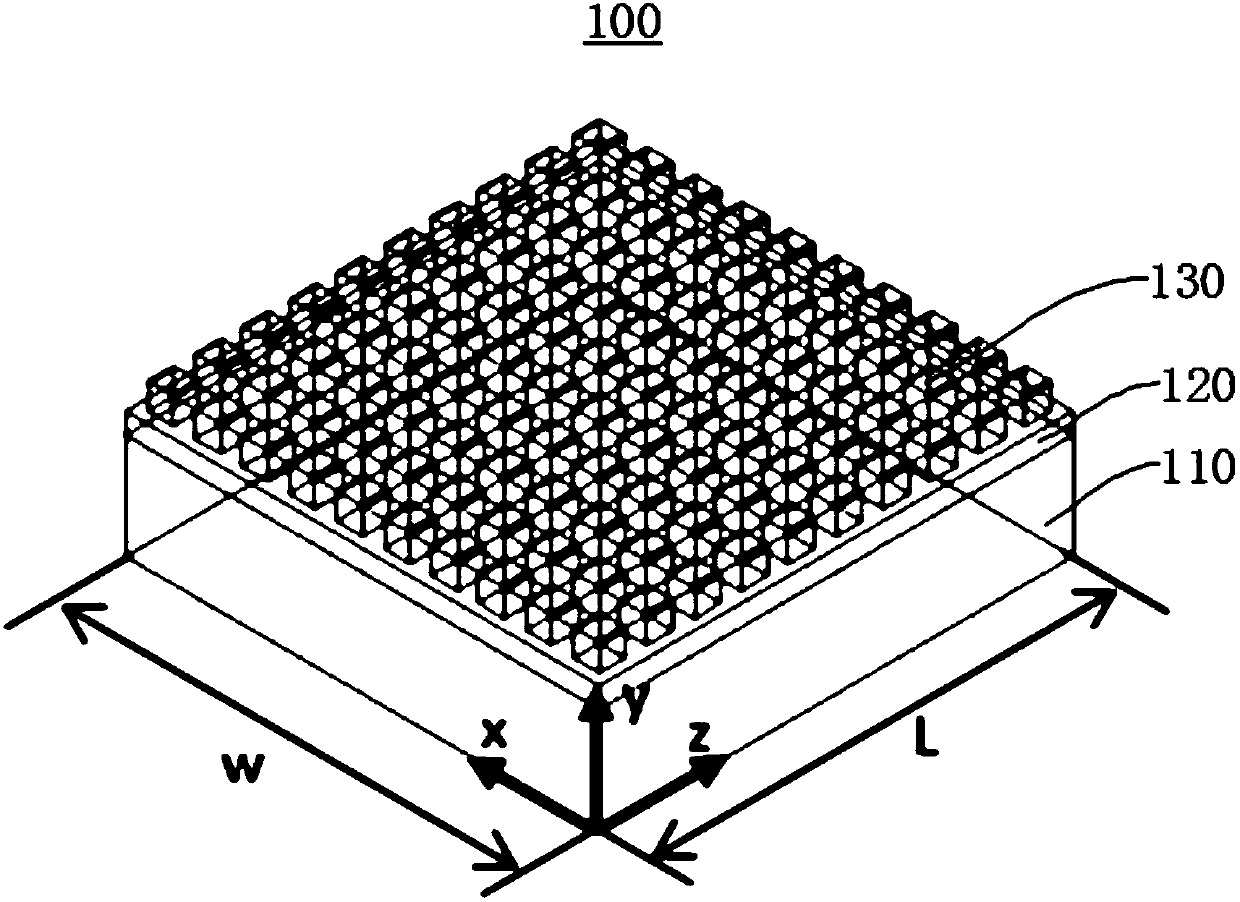

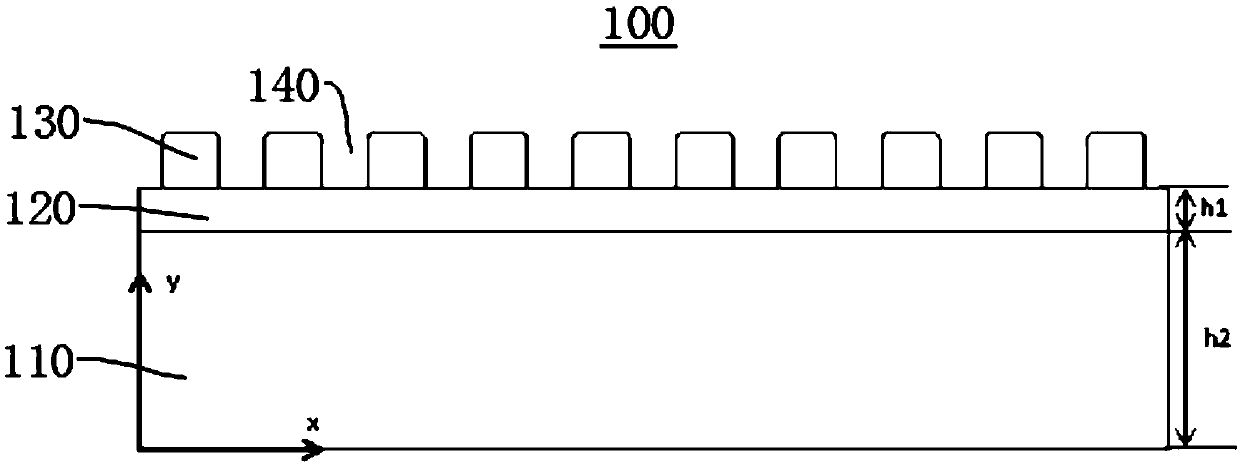

[0042] see figure 1 and figure 2, this embodiment provides a surface-enhanced Raman substrate 100, the surface-enhanced Raman substrate 100 is used to detect liquid samples, and the surface-enhanced Raman substrate 100 includes a substrate 110, a gold film 120 and gold nanocubes 130.

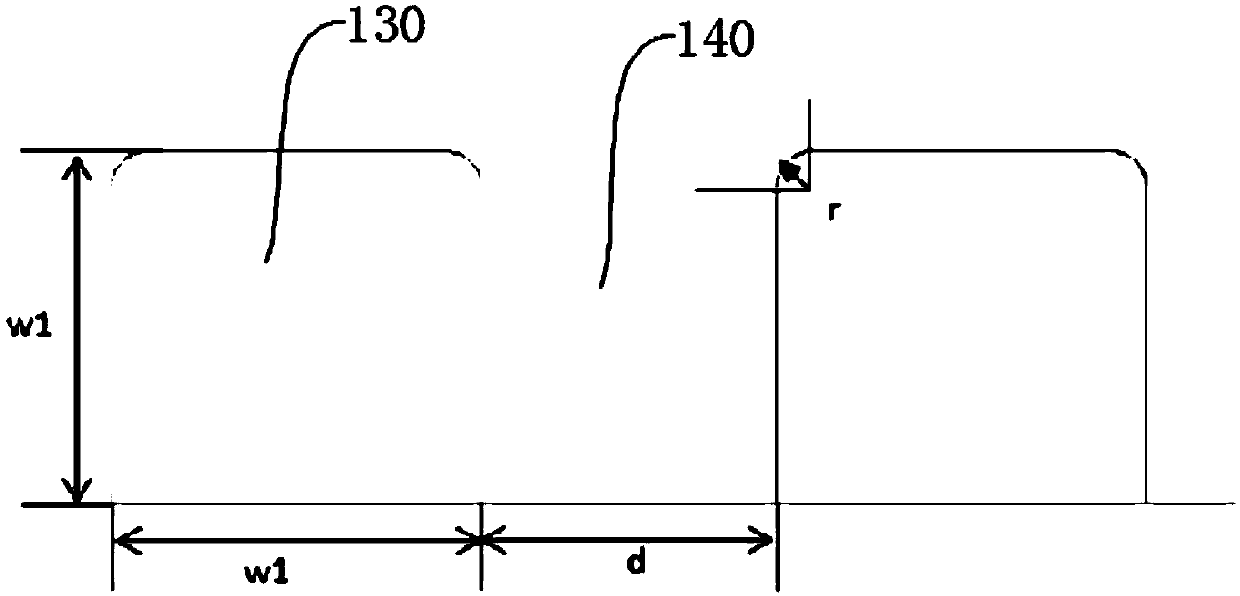

[0043] The substrate 110 is formed of silicon material, and the gold film 120 is disposed on the substrate 110 . Before forming the gold film 120 on the substrate 110 , a titanium layer is first formed on the substrate 110 , and then the gold film 120 is formed on the titanium layer. The gold nanocubes 130 are arranged on the gold film 120, and the gold nanocubes 130 are arranged in a matrix, and there are gaps 140 between the gold nanocubes 130, and the gaps 140 are used to inject liquid samples to be tested.

[0044] The substrate 110 has a cuboid structure, the length L of the substrate 110 is 2000 nm, the width W of the substrate 110 is 2000 nm, and the height h2 of the substrate 110 is 11...

no. 2 example

[0056] This embodiment provides a method for preparing a surface-enhanced Raman substrate, the method comprising:

[0057] S1: A silicon material is used to form a substrate.

[0058] The substrate 110 has a cuboid structure, the length L of the substrate 110 is 2000 nm, the width W of the substrate 110 is 2000 nm, and the height h2 of the substrate 110 is 110 nm.

[0059] S2: Depositing a titanium layer on the surface of the substrate, and plating a gold film on the titanium layer.

[0060] The gold film is formed by vacuum evaporation. The length of the gold film 120 is 2000 nm, the width of the gold film 120 is 2000 nm, and the gold film 120 completely covers the upper surface of the substrate 110 . The thickness of the gold film 120 is h1+W1=90nm.

[0061] S3: forming matrix-arranged gold nanocubes on the surface of the gold film by a metal lift-off method, with gaps between the gold nanocubes, and the gaps are used to inject liquid samples to be tested.

[0062] The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com