Graphene-modified culture solution for indoor hydroponic plants and preparation method of graphene-modified culture solution

A technology for graphene modification and hydroponic plants, applied in the field of soilless cultivation, can solve the problems of poor dispersion and uniformity of inorganic and organic nutrients, slow growth, hypoxia, etc., achieve good thermal conductivity and optical properties, and improve plant Good effect of photosynthetic reaction, dispersion and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

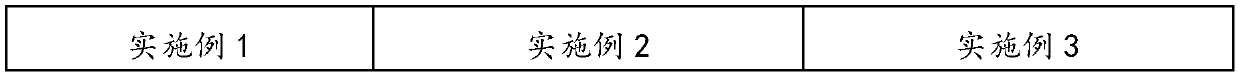

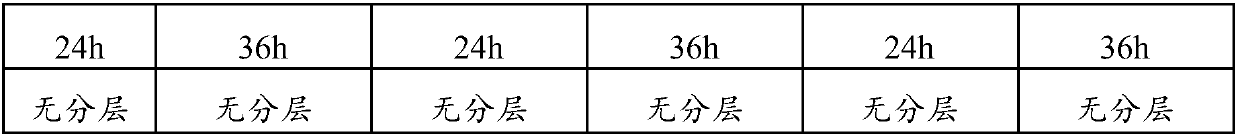

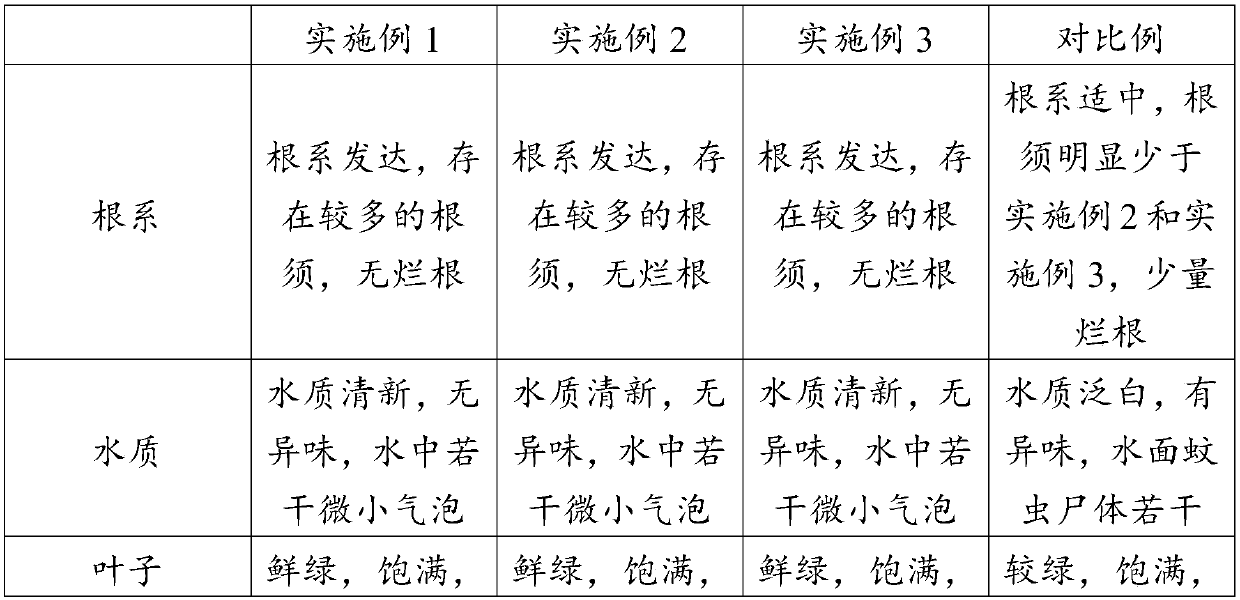

Embodiment 1

[0035] Graphene-modified indoor hydroponic plant culture fluid, said graphene-modified indoor hydroponic plant culture fluid is composed of basic culture fluid and ammonium polyphosphate-organobentonite / graphene composite nanomaterial additive, every 100 parts by weight of basic culture fluid Containing 8 parts by weight of ammonium polyphosphate-organobentonite / graphene composite nanomaterial additive;

[0036] The preparation method of graphene modified indoor hydroponic plant nutrient solution, described preparation method is as follows:

[0037] 1) Pour phosphoric acid with a mass fraction of 70% into the reactor, heat and stir, add urea and organic bentonite when the temperature rises to 75°C, add nanoscale graphene when the temperature rises to 110°C, and continue to heat up to Stir and react for 20 minutes at 120°C, then heat-treat the product at 160°C for 5 hours, cool to room temperature and perform nano-grinding to obtain ammonium polyphosphate-organic bentonite / grap...

Embodiment 2

[0047] Graphene-modified indoor hydroponic plant culture fluid, said graphene-modified indoor hydroponic plant culture fluid is composed of basic culture fluid and ammonium polyphosphate-organobentonite / graphene composite nanomaterial additive, every 100 parts by weight of basic culture fluid Containing 12 parts by weight of ammonium polyphosphate-organic bentonite / graphene composite nanomaterial additive;

[0048] The preparation method of graphene modified indoor hydroponic plant nutrient solution, described preparation method is as follows:

[0049] 1) Pour phosphoric acid with a mass fraction of 85% into the reactor, heat and stir, add urea and organic bentonite when the temperature rises to 80°C, add nanoscale graphene when the temperature rises to 120°C, and continue to heat up to Stir and react at 130°C for 10 minutes, then heat-treat the product at 180°C for 3 hours, cool to room temperature and perform nano-grinding to obtain ammonium polyphosphate-organic bentonite / g...

Embodiment 3

[0059] Graphene-modified indoor hydroponic plant culture fluid, said graphene-modified indoor hydroponic plant culture fluid is composed of basic culture fluid and ammonium polyphosphate-organobentonite / graphene composite nanomaterial additive, every 100 parts by weight of basic culture fluid Containing 10 parts by weight of ammonium polyphosphate-organic bentonite / graphene composite nanomaterial additive;

[0060] The preparation method of graphene modified indoor hydroponic plant nutrient solution, described preparation method is as follows:

[0061] 1) Pour phosphoric acid with a mass fraction of 80% into the reactor, heat and stir, add urea and organic bentonite when the temperature rises to 78°C, add nanoscale graphene when the temperature rises to 115°C, and continue to heat up to Stir and react for 15 minutes at 125°C, then heat-treat the product at 170°C for 4 hours, cool to room temperature and perform nano-grinding to obtain ammonium polyphosphate-organic bentonite / g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com