Rebar surface set cement cleaning equipment used in construction site

A surface cleaning and construction site technology, applied in the direction of manufacturing tools, cleaning methods and utensils, ceramic molding machines, etc., can solve the problems of incomplete cleaning, time-consuming and labor-intensive, steel bar damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

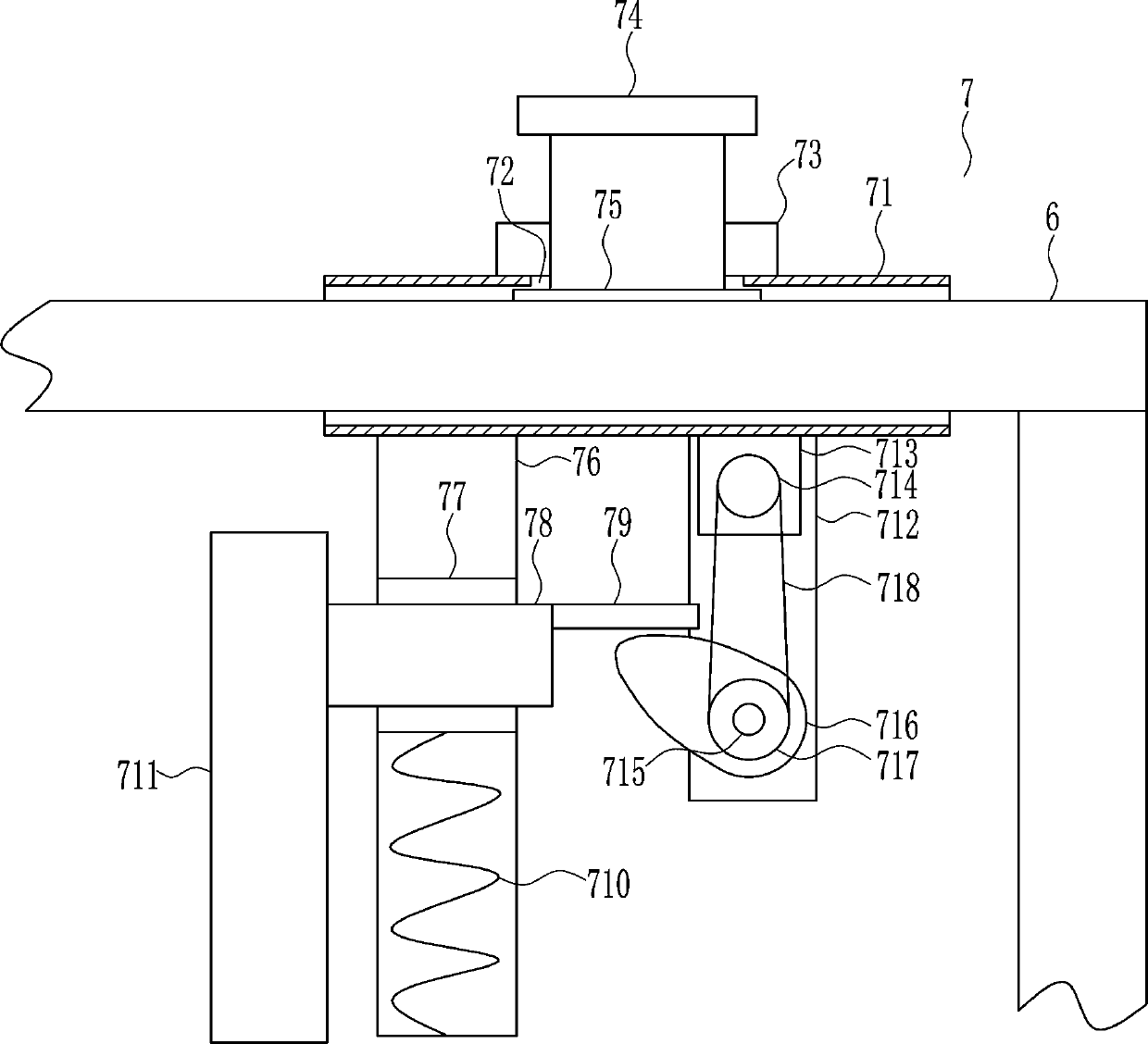

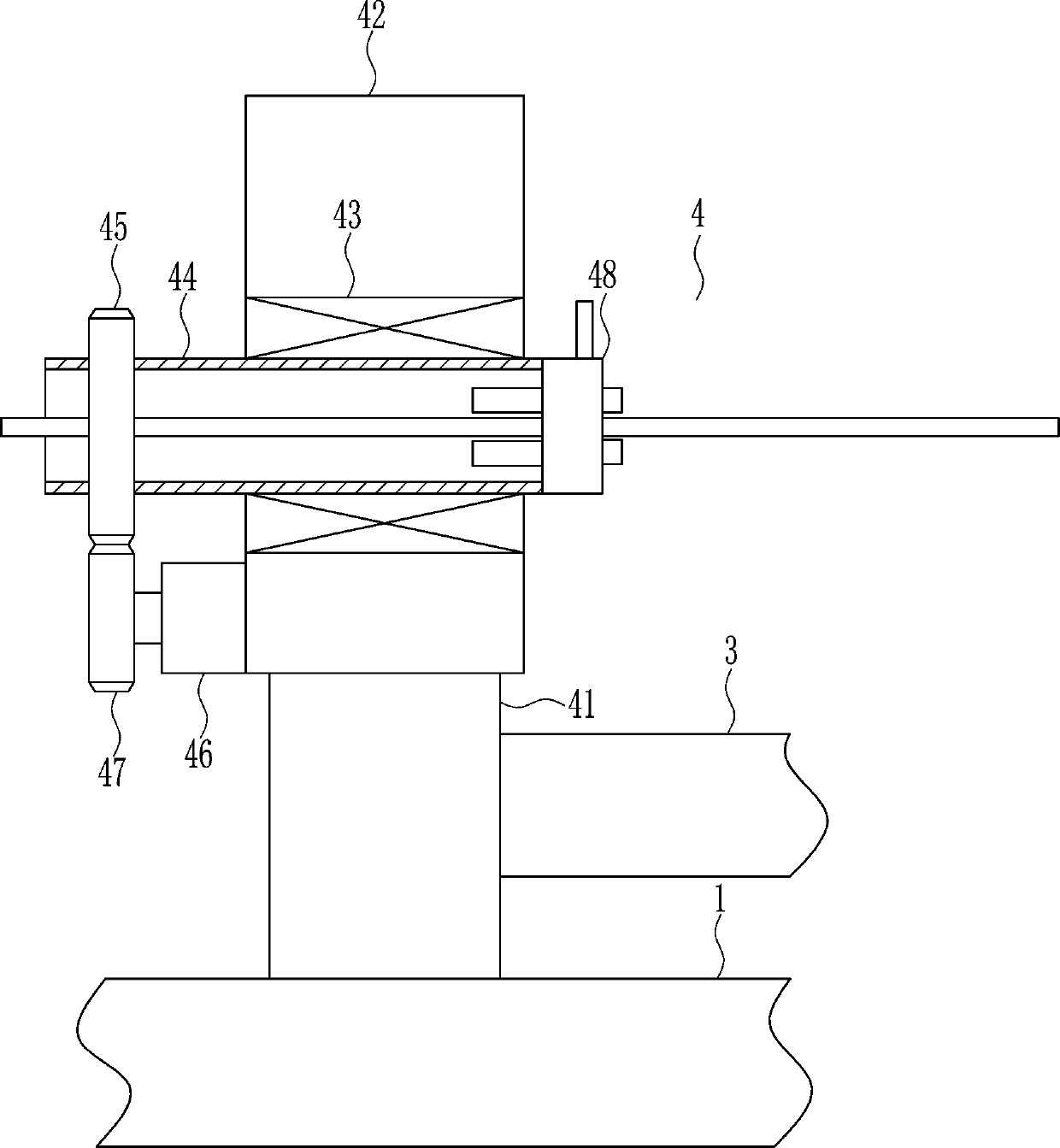

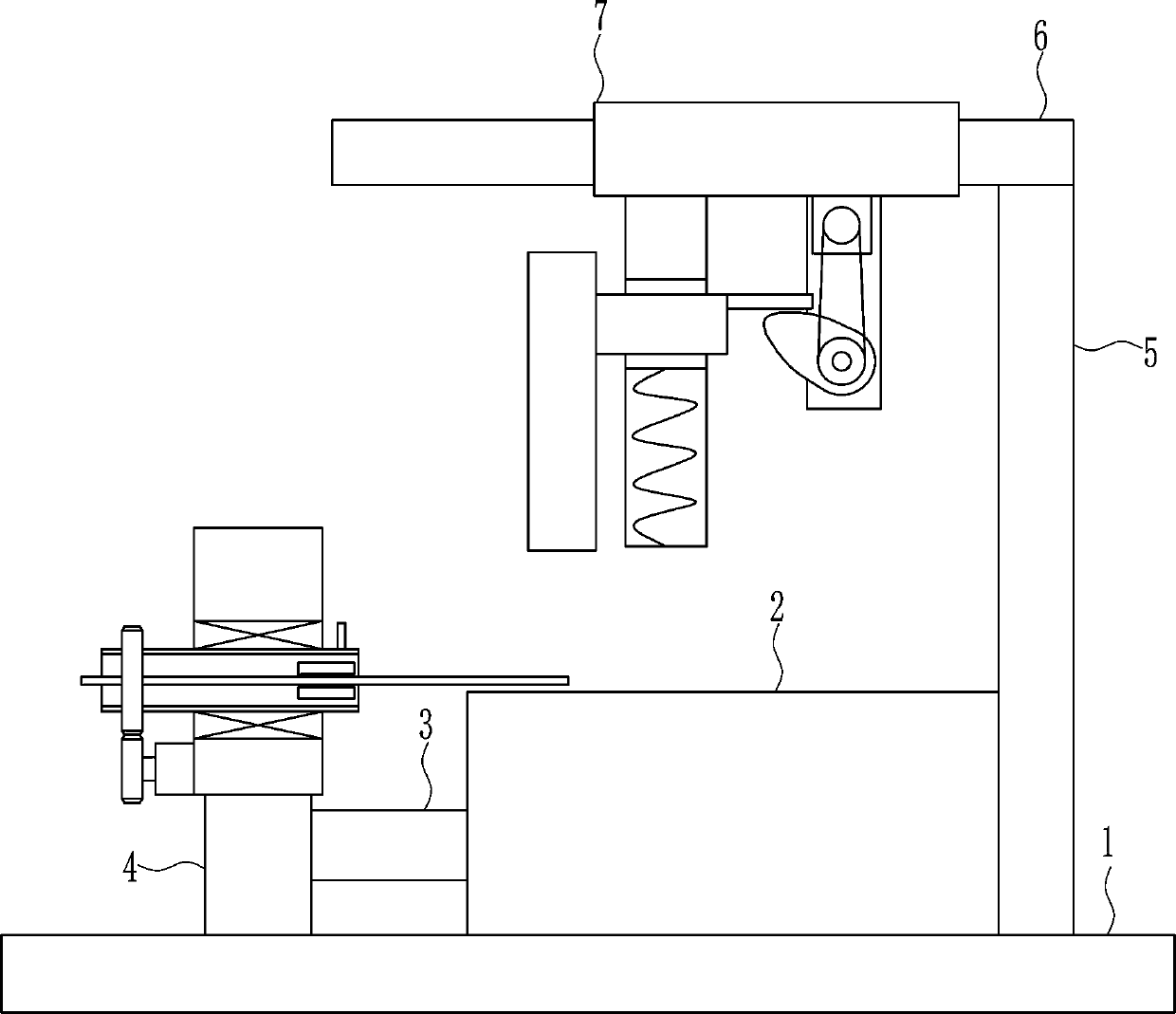

[0032] A kind of equipment for cleaning solidified cement on the surface of steel bars at a construction site, such as Figure 1-4 As shown, it includes a bottom plate 1, a placement table 2, a connecting rod 3, a fixing device 4, a support rod 5, a guide rail 6 and a vibration device 7. The upper right part of the bottom plate 1 is installed with a placement table 2 by welding, and A fixing device 4 is installed on the left side of the side, a connecting rod 3 is installed on the left end of the placing table 2 by welding, the right end of the connecting rod 3 is installed on the right side of the fixing device 4, and a support rod 5 is installed on the right side of the bottom plate 1 by welding, The support rod 5 is positioned at the right side of the placement table 2, and the upper end of the support rod 5 is equipped with a guide rail 6 by welding, and a vibrating device 7 is installed on the guide rail 6.

[0033] The fixing device 4 includes a supporting platform 41, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com