Synthesis method of discoid mordenite with different thickness

A technology of mordenite and synthesis method, which is applied in the direction of mercerized crystalline aluminosilicate zeolite, chemical instruments and methods, crystalline aluminosilicate zeolite, etc., can solve the problem of unfavorable catalytic activity, agglomeration of nano-zeolite crystals into spherical shapes, and reduction of catalytic reaction transmission. Mass rate and other issues, to achieve the effect of improving mass transfer and diffusion performance, improving regularity and smoothness, crystallinity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

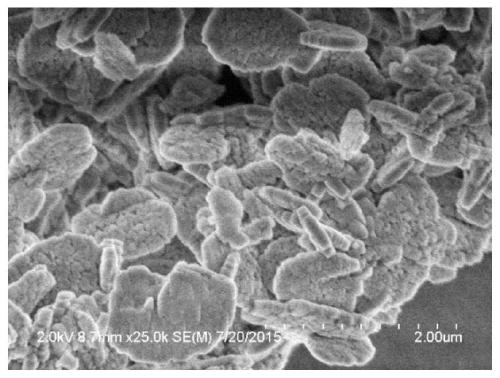

[0031] Dissolve 600 grams of water glass in 350 grams of water to form solution A; dissolve 65 grams of aluminum nitrate in 300 grams of water to form solution B; dissolve 125 grams of tetraethylammonium bromide in 150 grams of water to form solution c. Slowly add solution B to solution A dropwise, stir well and pour into solution C. Subsequently, AEO and dimethyl sulfone mixed oxygen-containing organic compounds with a molar ratio of 1:1 were added, so that the O / SiO 2 = 0.15, adjust the pH value of the gel solution with 95%wt concentrated sulfuric acid to 13, stir well at room temperature, and crystallize the formed gel at 180°C for 18 hours, filter and dry to obtain a molecular sieve sample, and synthesize the sample The SEM morphology of figure 1 shown.

Embodiment 2

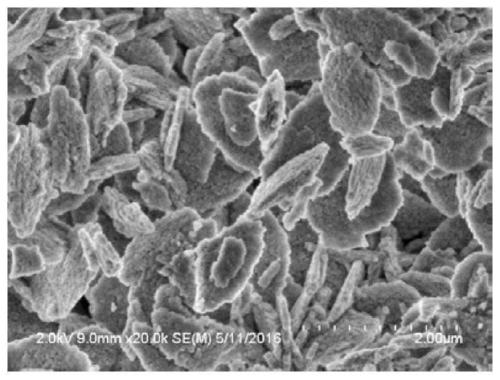

[0033] Dissolve 600 grams of water glass in 350 grams of water to form solution A; dissolve 65 grams of aluminum nitrate in 300 grams of water to form solution B; dissolve 125 grams of tetraethylammonium bromide in 150 grams of water to form solution c. Slowly add solution B to solution A dropwise, stir well and pour into solution C. Subsequently, AEO and dimethyl sulfone mixed oxygen-containing organic compounds with a molar ratio of 1:1 were added, so that the O / SiO 2 =0.005, adjust the pH value of the gel solution with 95%wt concentrated sulfuric acid to 13, stir well at room temperature, and crystallize the formed gel at 180°C for 18 hours, filter and dry to obtain a molecular sieve sample, and synthesize the sample The SEM morphology of image 3 shown.

Embodiment 3

[0035] Dissolve 600 grams of water glass in 350 grams of water to form solution A; dissolve 65 grams of aluminum nitrate in 300 grams of water to form solution B; dissolve 125 grams of tetraethylammonium bromide in 150 grams of water to form solution c. Slowly add solution B to solution A dropwise, stir well and pour into solution C. Subsequently, AEO and dimethyl sulfone mixed oxygen-containing organic compounds with a molar ratio of 1:1 were added, so that the O / SiO 2 = 0.3, adjust the pH value of the gel solution with 95%wt concentrated sulfuric acid to 13, stir well at room temperature, and crystallize the formed gel at 180°C for 18 hours, filter and dry to obtain a molecular sieve sample, and synthesize the sample The SEM morphology of Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com